High-efficiency arc discharge preparation device of metal powder for 3D printing

A metal powder and arc discharge technology, which is applied in the field of high-efficiency arc discharge preparation devices for metal powders for 3D printing, can solve the problems of increasing electrical conductivity, affecting preparation efficiency, particle ablation damage, etc., to control the action time, improve preparation efficiency, Protects the effect of excessive ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

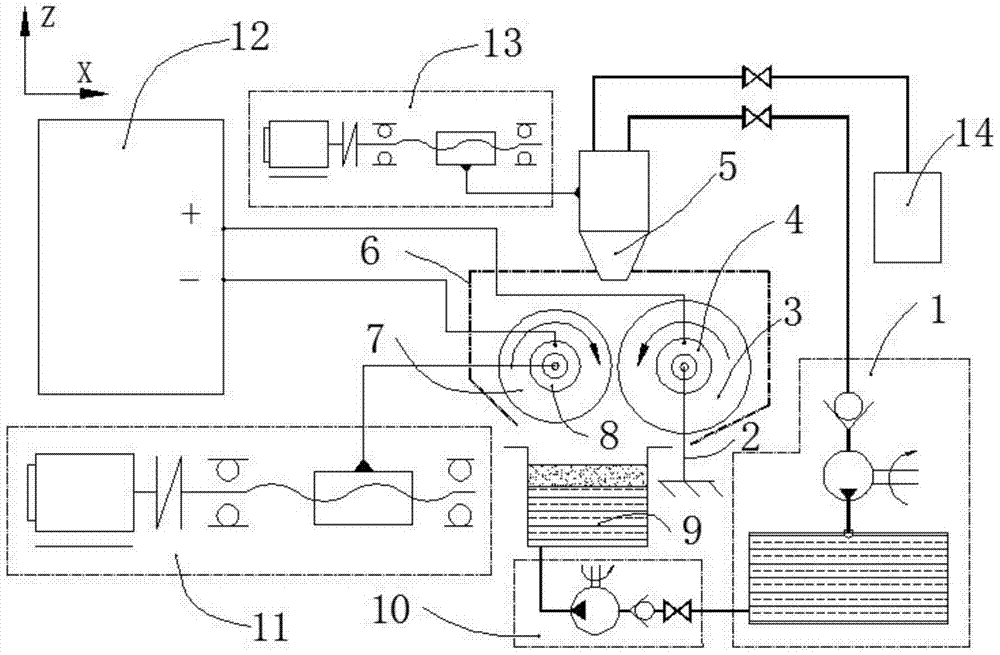

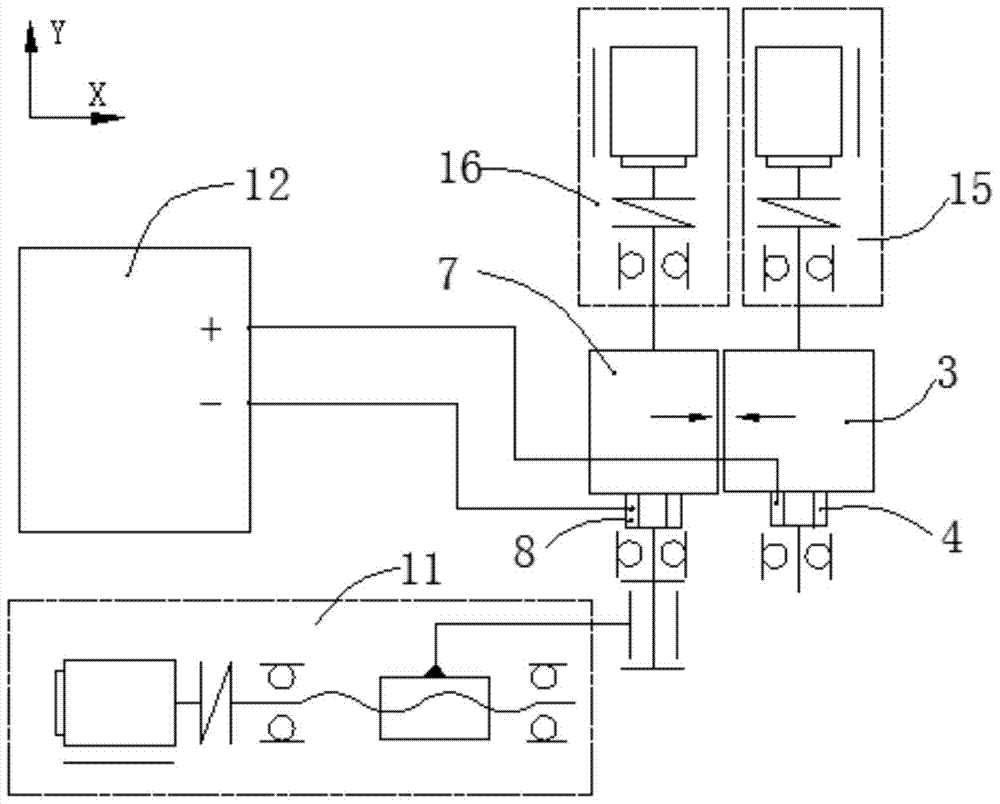

[0027] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the X-Z direction of the metal powder high-efficiency arc discharge preparation device for 3D printing of the present invention; figure 2 It is a schematic diagram in the X-Y direction of the high-efficiency arc discharge preparation device for metal powder for 3D printing of the present invention. As shown in the figure, a metal powder high-efficiency arc discharge preparation device for 3D printing includes a liquid supply system 1, a liquid pumping system 10, a gas supply system 14, a discharge power supply 12, a support seat 2, a main roller 3, and a main roller Electric brush 4, nozzle 5, baffle plate 6, slave roller 7, slave roller brush 8, collecting and filtering device 9, slave roller movement guiding mechanism 11, nozzle movement guiding mechanism 13, main roller pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com