Reinforced waste soil dumper back door

A dump truck and enhanced technology, which is applied to doors, vehicle parts, transportation and packaging, etc., can solve the problems of poor deformation resistance of the back door, and achieve the effects of enhanced deformation capacity, increased strength, and strong bending deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

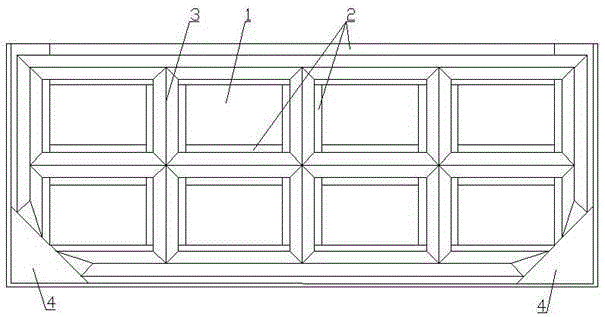

[0015] Reinforced muck dump truck rear door, including door panel 1. A reinforcing rib 2 is welded on one end surface of the door panel, and the reinforcing ribs 2 are distributed on the end surface of the door panel 1 in a grid pattern in a criss-cross pattern.

[0016] The upper end of the reinforcement rib 2 is welded with a triangular prism-shaped strip angle steel 3 , and the strip angle steel 3 is connected to each other and criss-crossed to form a grid and is welded on the upper end of the reinforcement rib 2 .

[0017] The door panel 1 is welded with a triangular steel plate 4 at the corner of the end face on the side with the reinforcing rib 2, and there are two triangular steel plates 4, which are respectively welded at the upper and lower corners of the side opposite to the side where the door shaft is installed on the door panel 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com