High-temperature waste recycling type embedded scraper transporter

A technology of buried scraper conveyor and waste recycling, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., which can solve the problem of damaged equipment and achieve the effect of reducing the operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

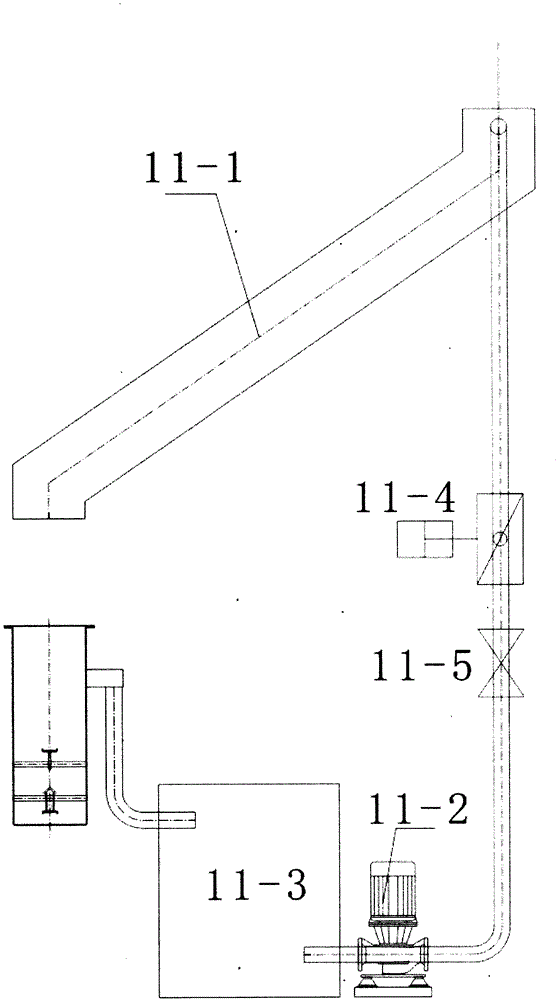

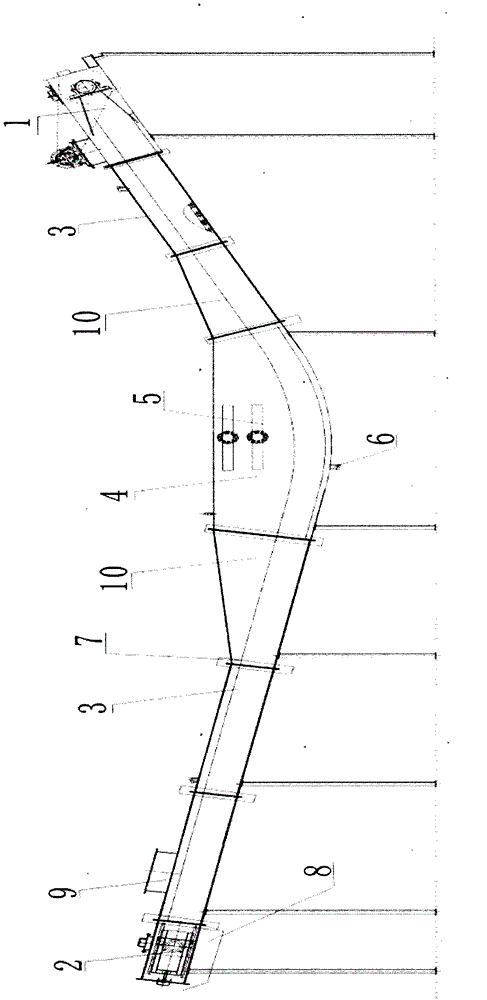

[0015] Such as figure 1 As shown, the high-temperature waste recovery type buried scraper conveyor includes the head 1 of the buried scraper conveyor, the tail 2 of the buried scraper conveyor, the middle section 3 of the buried scraper conveyor, and the feeding of the buried scraper conveyor Section 9, the transition section 10 of the buried scraper conveyor.

[0016] The buried scraper conveyor is provided with a settling section 4, the settling section 4 is provided with a plurality of overflow outlets 5, the lower part of the settling section 4 is provided with a filter and drainage holes 6, and the settling section 4 is provided with a space occupying device . The settling section 4 is curved in terms of its geometric dimensions. When bulk materials are conveyed in a curved space, the interengaging force space between materials is easily destroyed and difficult to convey. The space occupying device is to add a set of devices in the curved sedimentation section to reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com