Curved block vibrating pulp extraction device

A curved block and vibration transmission technology, used in biochemical cleaning devices, enzymology/microbiology devices, biochemical instruments, etc., can solve problems such as low efficiency and large labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

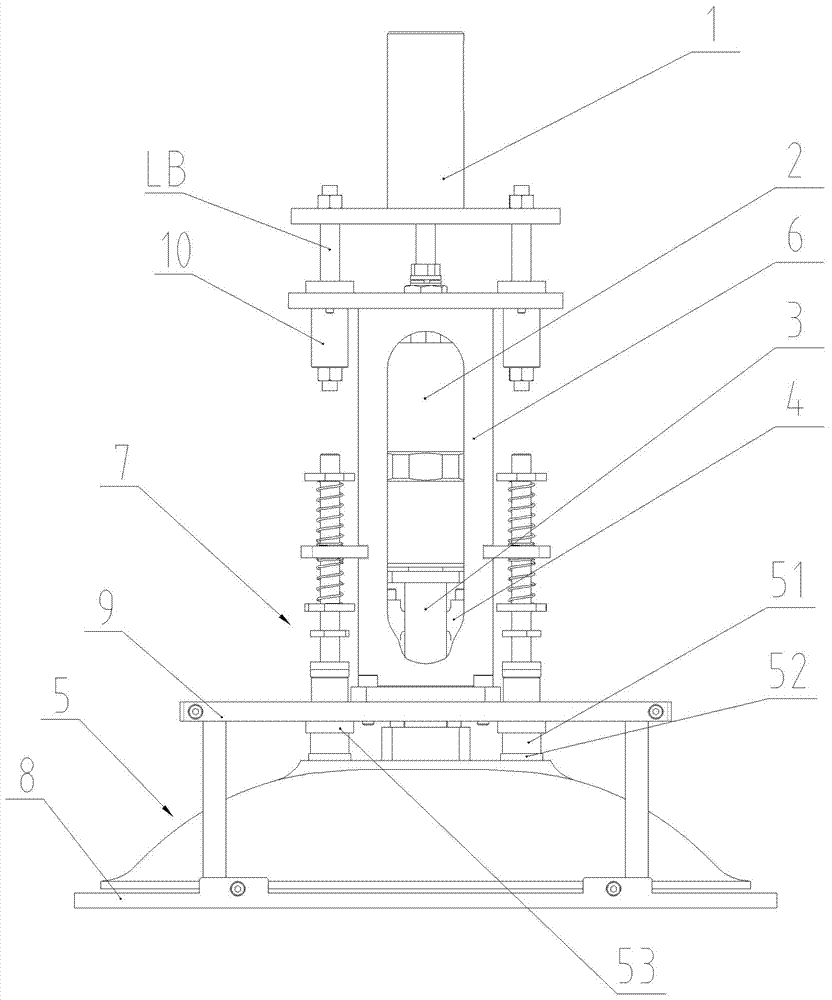

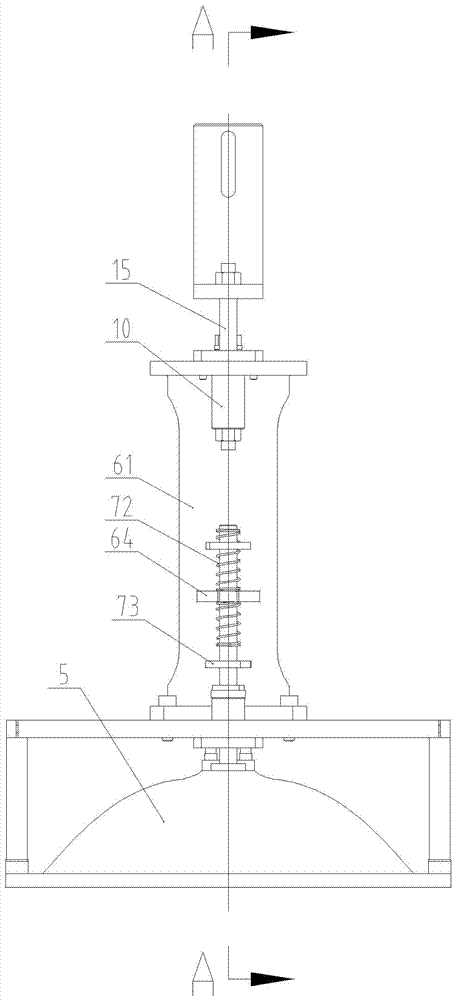

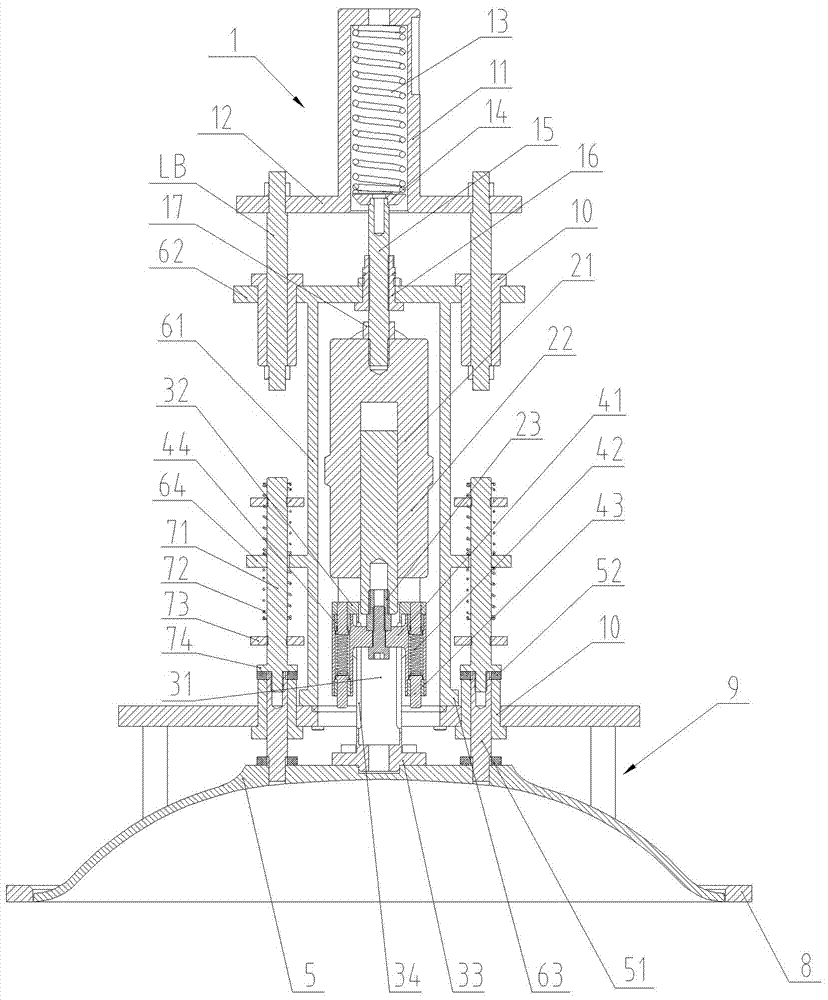

[0020] Such as Figure 1 to Figure 4 As shown, this embodiment discloses a curved block vibration extracting device, including a fixed connection head 1, a pneumatic vibrator 2, a vibration transmission shaft assembly 3, a blocking block assembly 4, a vibration shaping mold 5, a pillar 6, and an elastic buffer assembly 7. Press frame 8. Table-type fixed frame 9. Extended flange linear bearing 10.

[0021] The pressure frame 8 is a rectangular frame, and the vibration shaping mold 5 is a turtle-back-shaped cover in the middle of the bottom edge of the rectangle, which is fixed in the inner cavity of the pressure frame 8 with the bottom edge, and the table-shaped fixing frame 9 is connected to the upper side of the pressure frame 8. The top plate of type fixed mount 9 is positioned at the top of vibration shaping mold 5 tops.

[0022] Two upward connecting shafts 51 are connected to the two ends in the length direction of the top of the vibration shaping mold 5, and flange line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com