Low-speed electronic jacquard device

An electronic jacquard, low-speed technology, used in jacquard machines, textiles, textiles and papermaking, etc., can solve the problems of high component cost, low work efficiency, poor stability, etc., to achieve compact structure, cost reduction, easy assembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The structure and principle of the present invention will be further described below in conjunction with the accompanying drawings.

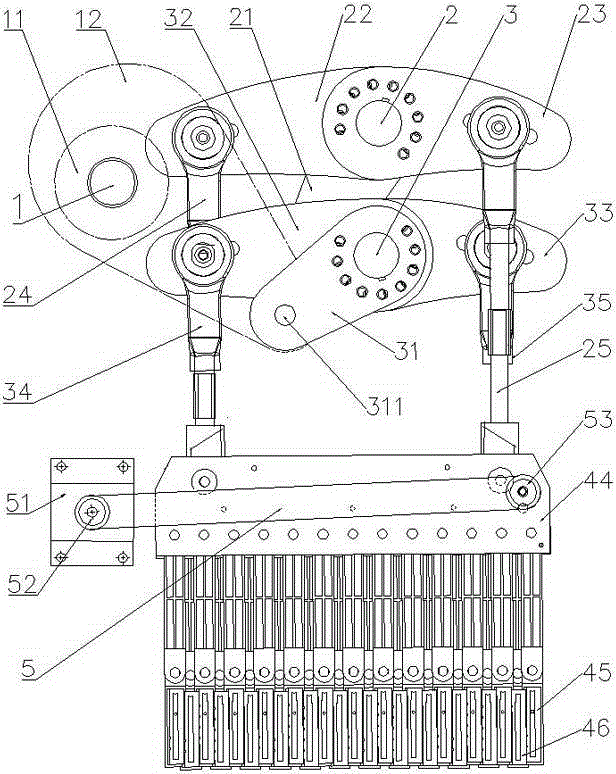

[0030] see figure 1 , provides a low-speed electronic jacquard device for electronic jacquard and warp selection, the whole machine is compact in structure, easy to assemble and maintain, low in cost, light in weight and excellent in performance.

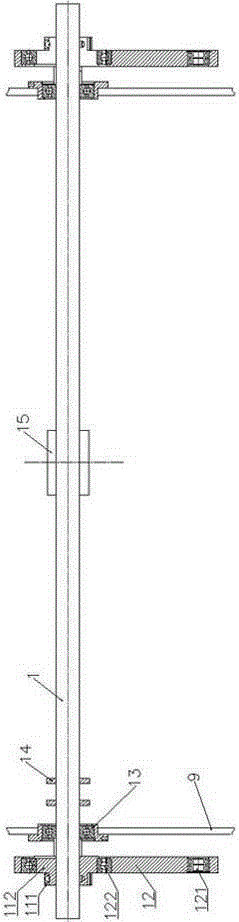

[0031] Since this device is Figure 4 As shown, the structures on the left and right sides of the frame 9 are basically the same, so in this embodiment, the structure on the left side of the frame 9 is used to illustrate the specific implementation of the embodiment. If the structure on the right side of the frame 9 is different from the left side, will be described separately.

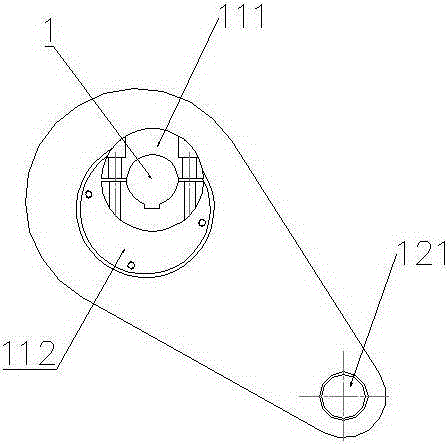

[0032] A low-speed electronic jacquard device, comprising: a casing and a frame 9 arranged in the casing, a driving shaft 1 is arranged on the frame 9, and two driven shafts arranged up and down on the same vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com