A rare earth permanent magnet material added with yttrium and its preparation method

A rare-earth permanent magnet and rare-earth element technology, which is applied in the fields of magnetic materials, metal processing equipment, inductors/transformers/magnets, etc., can solve the problems of reducing the saturation magnetization of alloys, fast consumption of dysprosium metal, and constant magnetic polarization. , to achieve the effect of reducing viscosity, filling the gap in magnet performance, and improving magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Another aspect of the present invention provides a kind of preparation method of the rare earth permanent magnet material that adds yttrium as described above, comprises the steps:

[0063] (1) Melting an alloy containing Sm, Y and Fe as main components and adding Co and / or Nb elements into an ingot, melting at a high temperature, casting to a rotating roller, and rotating and quenching to obtain a quenched thin strip;

[0064] (2) The ingot is melted at a high temperature and cast to a rotating roller, and then rotated for rapid quenching and cooling to obtain a rapid quenching thin strip;

[0065] (3) quenching the quick-quenched strip obtained in step (2) after crystallization treatment, and then pulverizing into alloy powder;

[0066] (4) Nitriding the alloy powder obtained in step (3) in a tube furnace to obtain the yttrium-added rare earth permanent magnet material.

[0067] The rare earth required for the prepared raw material adopts a single rare earth metal. ...

Embodiment 1

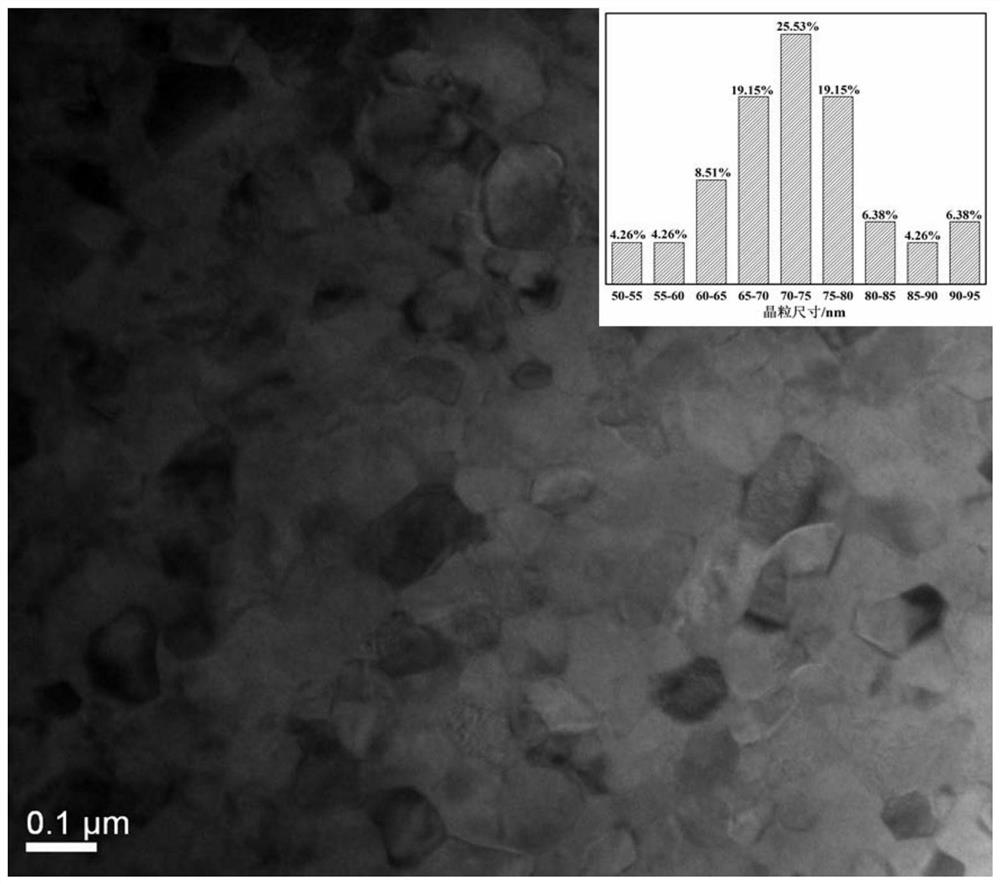

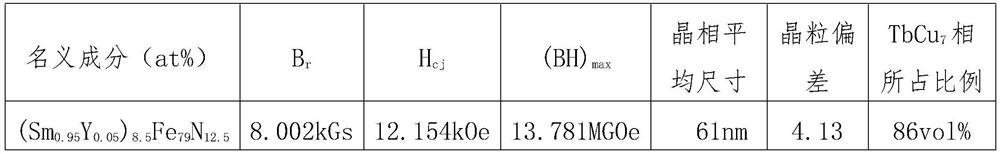

[0103] The permanent magnetic material prepared in this embodiment has the following alloy composition (Sm 0.95 Y 0.05 ) 8.5 Fe 79 N 12.5 (at%) permanent magnet, concrete steps are as follows:

[0104] (1) A master alloy equipped with the above alloy components, wherein the Sm, Y, and Fe elements in the raw materials are all added in the form of pure metals, and then the following steps are used to prepare the SmFeN rare earth permanent magnet material.

[0105] (2) Put the prepared raw materials into a vacuum electric arc furnace to melt evenly, turn off the current and wait for the alloy liquid to cool to obtain a master alloy ingot. Put the prepared ingot into the high-vacuum single-roll spin quenching equipment. 6 Cooling at ℃ / s cooling rate. Among them, the rapid cooling and quick quenching process is carried out under a protective atmosphere, and the alloy liquid is sprayed onto the roller rotating at a wheel speed of 35m / s to obtain a quick quenched thin strip.

...

Embodiment 2

[0113] The permanent magnetic material prepared in this embodiment has the following alloy composition (Sm 0.8 Y 0.2 ) 8.5 Fe 79 N 12.5 (at%) permanent magnet, concrete steps are as follows:

[0114] (1) A master alloy equipped with the above alloy components, wherein the Sm, Y, and Fe elements in the raw materials are all added in the form of pure metals, and then the following steps are used to prepare the SmFeN rare earth permanent magnet material.

[0115](2) Put the prepared raw materials into a vacuum electric arc furnace to melt evenly, turn off the current and wait for the alloy liquid to cool to obtain a master alloy ingot. Put the prepared ingot into the high-vacuum single-roll spin quenching equipment. 5 Cooling at ℃ / s cooling rate. Among them, the rapid cooling and quick quenching process is carried out under a protective atmosphere, and the alloy liquid is sprayed on the roller rotating at a wheel speed of 30m / s to obtain a quick quenched thin strip.

[011...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com