Diesel fork lift truck recycling method and installation package

A technology for internal combustion forklifts and installation kits, which is applied in the field of recycling and reuse of internal combustion forklifts, and can solve problems such as large changes, difficult implementation, and failure to meet modification requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

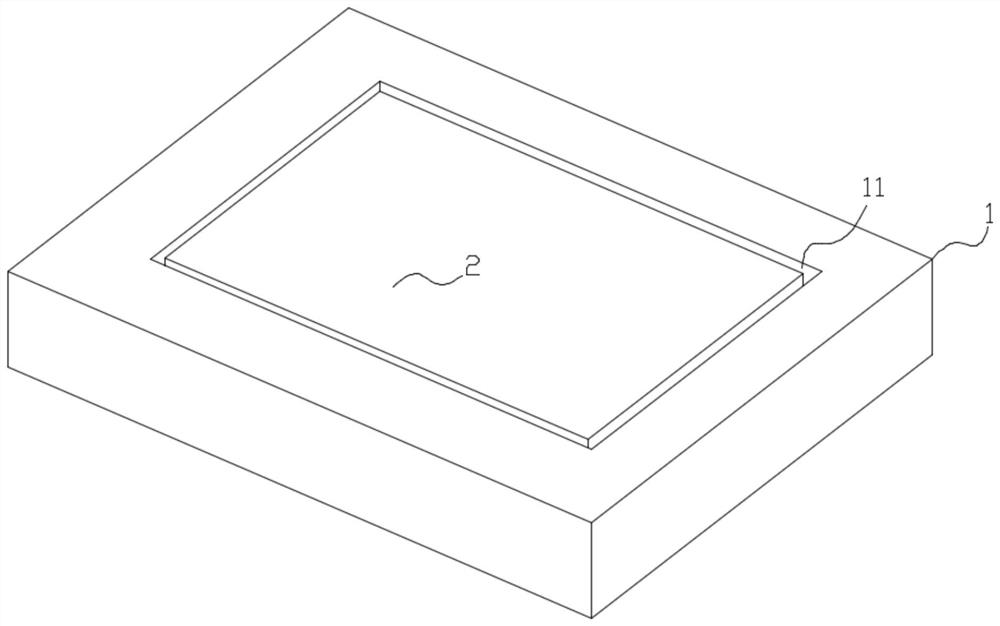

[0039] See figure 1 ,At figure 1 Among them, the vehicle frame 1 is the body frame of the original internal combustion forklift. After removing such as the engine, gearbox, air filter, water tank radiator, internal combustion forklift instrument panel, oil pipe, cooling water pipe, wiring harness, etc., the middle part is formed. The accommodating space 11 accommodated and assembled by the bag 2, because different vehicle frames themselves have differences in size and structure, etc., therefore, the accommodating space 11 can have a variety of spatial configurations, which can be irregular, open spaces or multiple continuous spaces. In order to facilitate understanding, only a relatively intuitive spatial configuration is shown here for illustration;

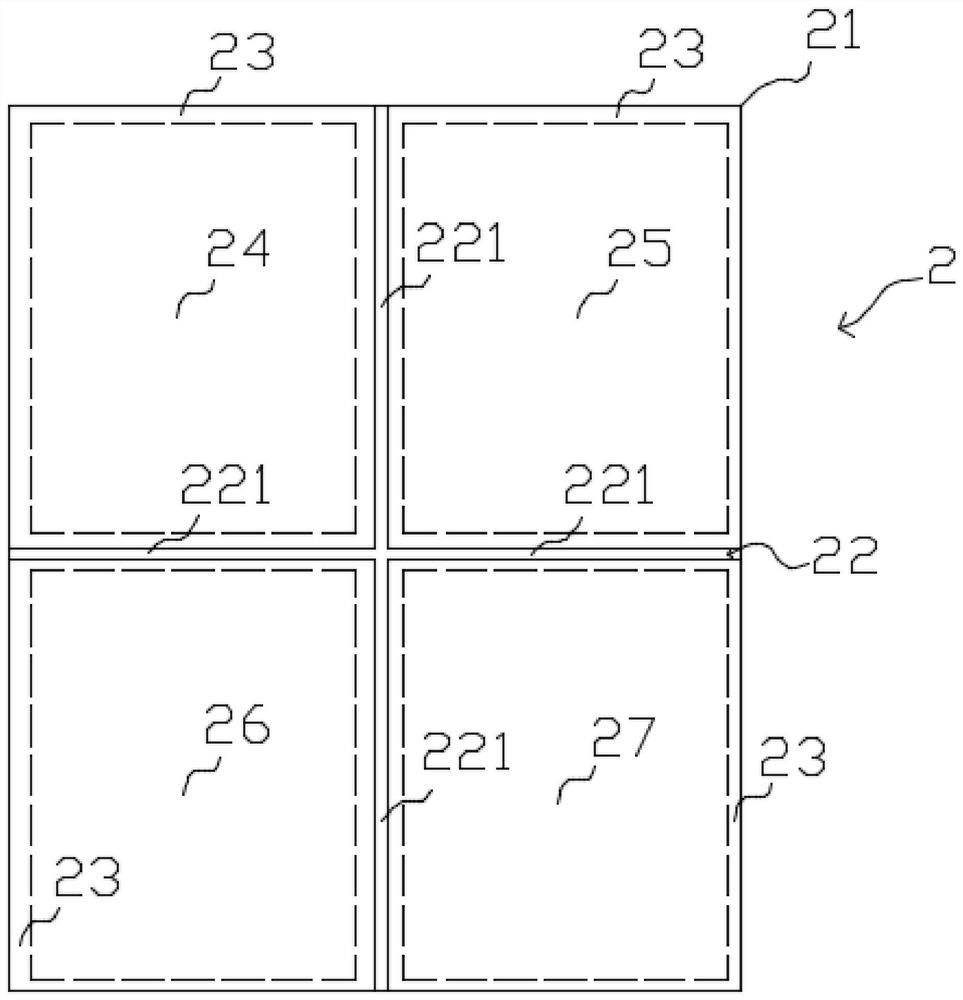

[0040] See figure 2 , figure 2 It is a perspective view of the installation package 2 from a top view angle. In the illustration, each integrated component is distributed in the space in the same horizontal direction, and t...

Embodiment 2

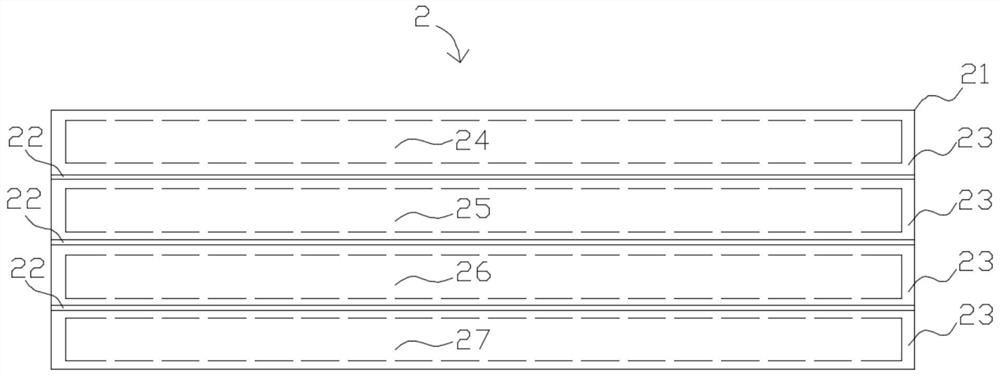

[0043] See image 3 , image 3 It is a perspective structural diagram of the installation package 2 on the side. The difference from Embodiment 1 is that each integrated component is distributed in the space in the vertical direction, and the storage space is divided into multiple independent assembly rooms by multiple laminates ;

[0044] The integrated components include integrated component one 24, integrated component two 25, integrated component three 26 and integrated component four 27, each of the integrated components includes the power integrated component, power integrated component or control integrated component, etc., independent of each other Each is located in the assembly chamber 23; it should be pointed out that, in order to distinguish the above-mentioned various integrated components in the independent assembly chamber 23, in this embodiment, a laminate 22 is used to block it, and the laminate 22 is arranged layer by layer from top to bottom, and each integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com