C/C-SiC-ZrC-ZrB2 complex-phase ceramic-based frictional braking material and preparation method thereof

A friction brake material, ceramic technology, applied in friction linings, ceramic layered products, chemical instruments and methods, etc., can solve the problem of reduced friction coefficient, poor high temperature oxidation resistance, difficult to meet the all-weather and complex service of aircraft, etc. problems, to achieve the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

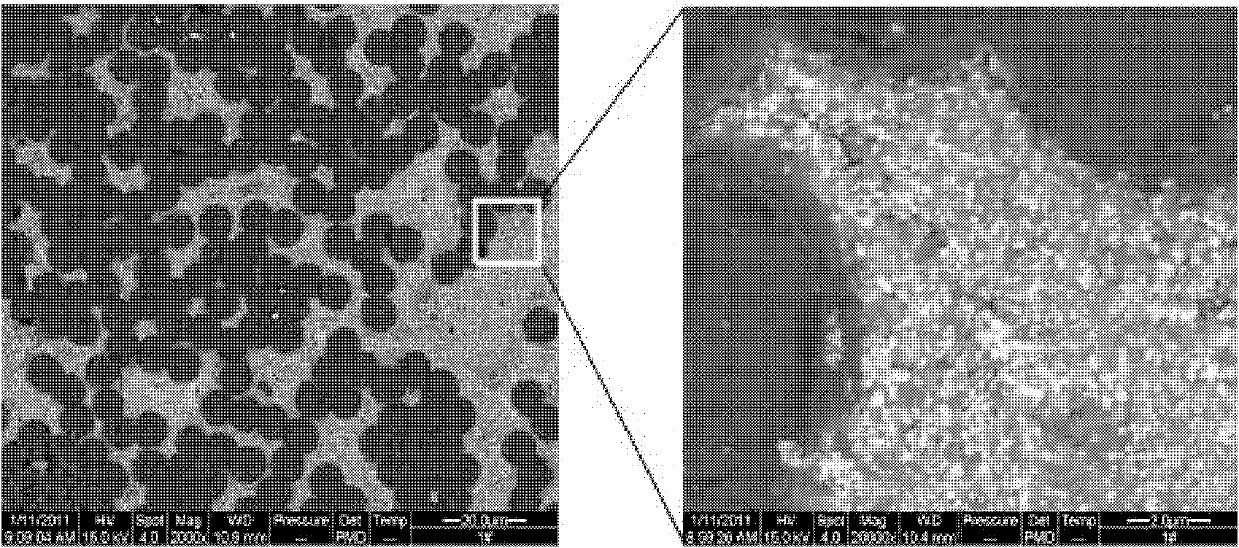

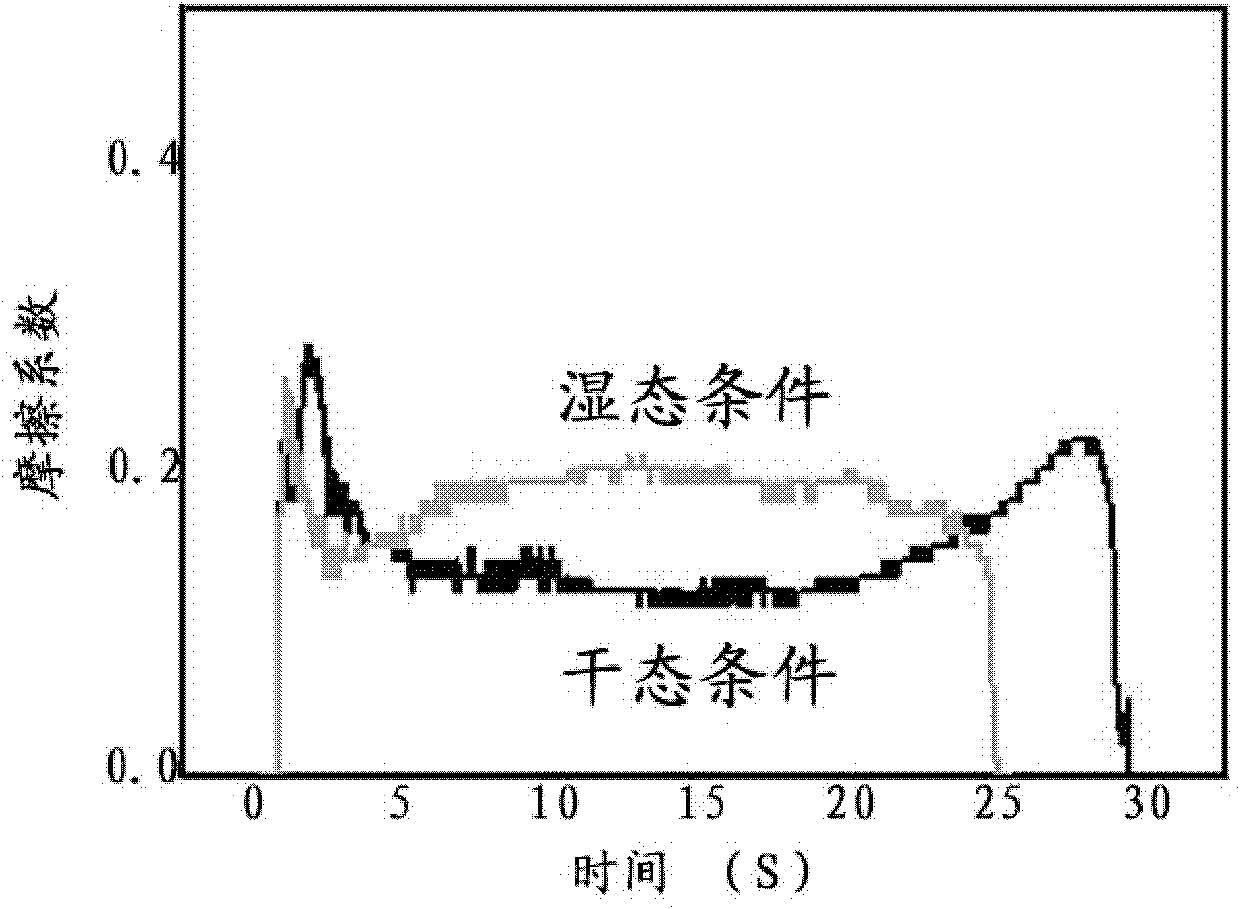

Image

Examples

Embodiment 1

[0037] The carbon fiber prefabricated body is made of T700 12K PANCF non-weft carbon cloth and a layer of T700 12K PANCF carbon fiber mesh tire, which is continuously needle-punched to form an integral structure fabric with a volume density of 0.28g / cm 3 .

[0038] Using methane as a carbon source, a chemical vapor deposition furnace is used to deposit a pyrolytic carbon interface layer on the carbon fiber surface of a carbon fiber preform. The process conditions are as follows: the deposition temperature is 1000°C, the total pressure is 5kPa; the methane flow rate is 2L / min, and the deposition time is 20h; the bulk density of the material obtained after deposition is 0.55g / cm 3 .

[0039] Use polycarbosilane, polycarbozircone, and polycarbaborazane as the multiphase ceramic precursors, and prepare solutions with xylene at a mass ratio of 50%, and then mix the three solutions at a mass ratio of 1:4:4 Dubbed as a multiphase ceramic precursor solution. Put the carbon fiber pr...

Embodiment 2

[0041] The carbon fiber prefabricated body is made of T700 12K PANCF non-weft carbon cloth and a layer of T700 12K PANCF carbon fiber net tire, and the overall structure fabric is formed by continuous needle punching, with a volume density of 0.50g / cm 3 .

[0042] Using propane as a carbon source, a chemical vapor deposition furnace is used to deposit a pyrolytic carbon interface layer on the carbon fiber surface of a carbon fiber preform. The process conditions are as follows: the deposition temperature is 950°C, the total pressure is 10kPa, the propane flow rate is 4L / min, the deposition time is 10h, and the bulk density of the deposited material is 0.81g / cm 3 .

[0043] Use polycarbosilane, polycarbozircone, and polycarbaborazane as the precursors of multiphase ceramics, and prepare solutions with xylene at a mass ratio of 50%, and then mix the three solutions at a mass ratio of 1:4:2 Dubbed as a multiphase ceramic precursor solution. Put the carbon fiber prefabricated bod...

Embodiment 3

[0045] The carbon fiber preform is woven into a 2.5D overall structure fabric with T700 carbon fiber, and the volume density is 0.82g / cm 3 .

[0046] Using propane as a carbon source, a pyrolytic carbon interface layer was prepared on the carbon fiber surface of a carbon fiber preform using a chemical vapor deposition furnace. The process conditions are as follows: the deposition temperature is 950°C; the total pressure is 10kPa; the propane flow rate is 4L / min; the deposition time is 10h, and the density of the deposited material reaches 1.1g / cm 3 .

[0047] Using polycarbosilane, polycarbozircone, and polycarbaborazane as the precursors of multiphase ceramics, they were formulated into solutions with toluene at a mass ratio of 50%, and then the three solutions were mixed at a mass ratio of 1:2:4. Form a multiphase ceramic precursor solution. Put the carbon fiber prefabricated body deposited with the pyrolytic carbon interface layer in a vacuum container, add the multiphas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com