A vehicle transmission control device

A technology for operating devices and transmissions, applied in transmission control, components with teeth, belts/chains/gears, etc., can solve problems such as poor shifting smoothness, complicated changes in gear shifting resistance, etc., and reduce wear and collision. , Improve the operating feel and reduce the effect of the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

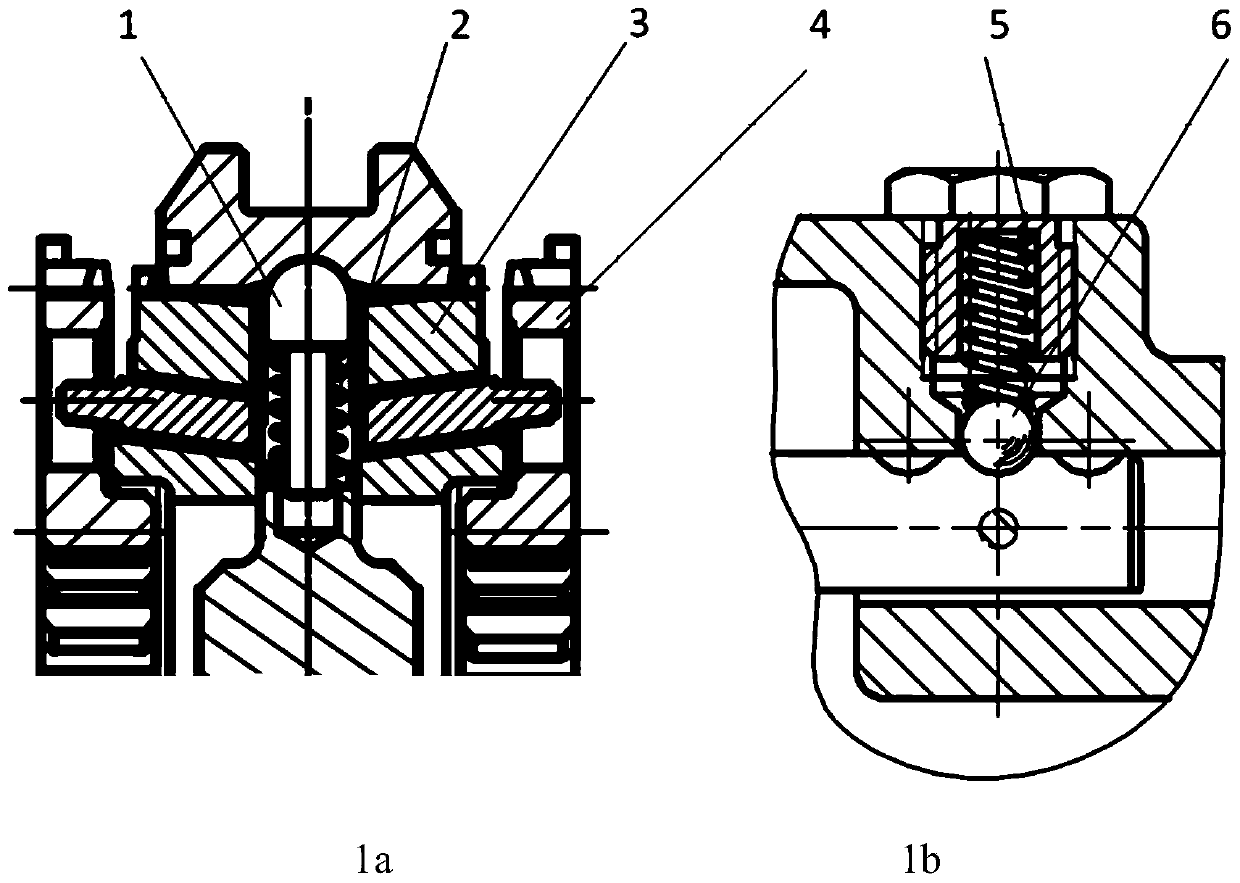

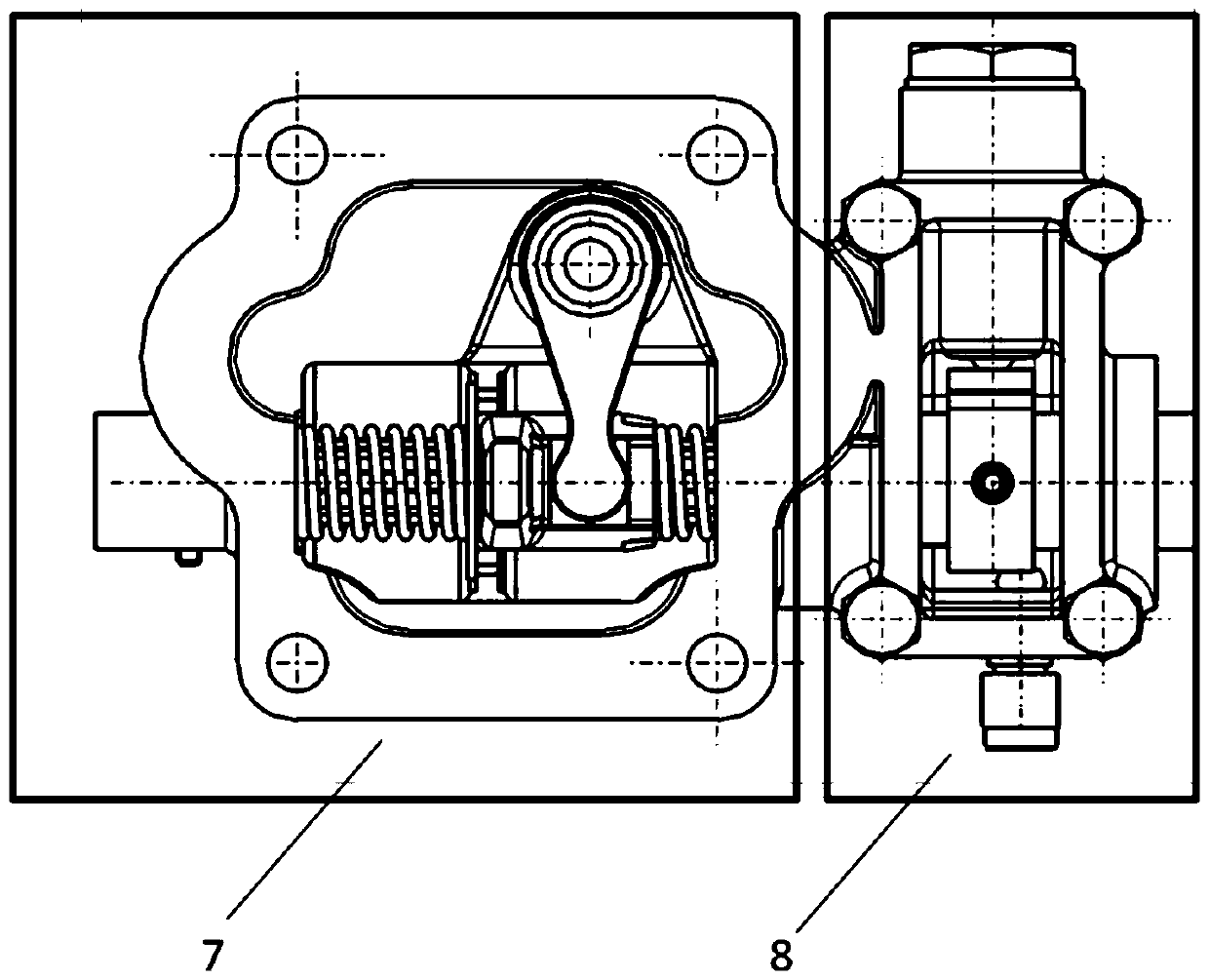

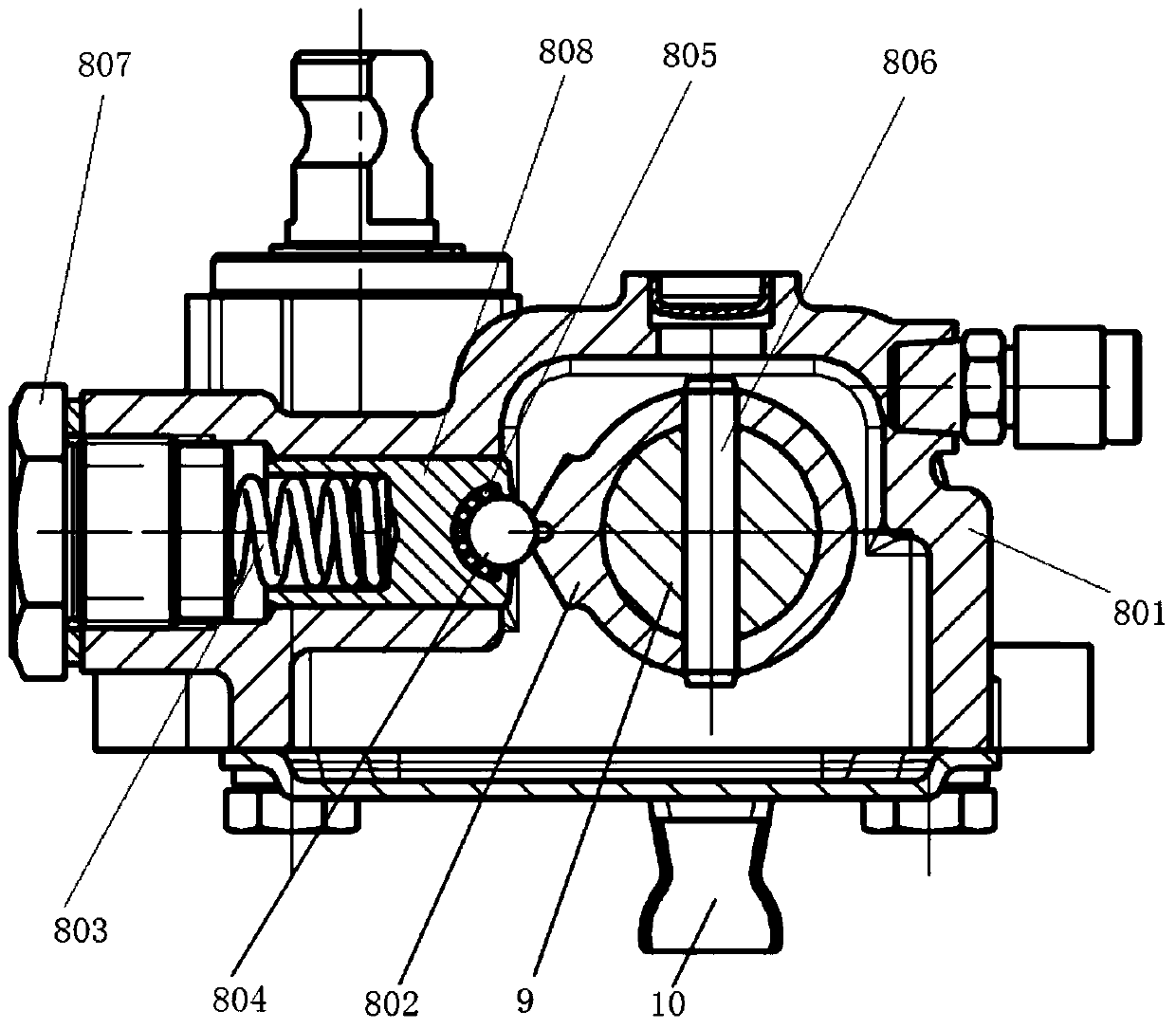

[0024] The invention relates to a vehicle transmission control device, which can especially improve the control performance of a light truck transmission. The present invention adds a central locator 8 on the basis of the original selection / shift device assembly 7. As shown in FIG. Column pin 808 realizes the neutral positioning of the shift head 10, such as image 3 As shown, the positioning cam 802 is designed to be V-shaped. Preferably, the steel ball at the head of the self-locking column pin 808 can accurately position the dial in the neutral position, and properly adjust the stiffness and preload of the self-locking compression spring 803, V The raised shape of the font, including the opening angle and the shape of the two sides, etc., on the one hand, can ensure the precise positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com