Sealing device for high-temperature and high-pressure rotating machinery

A high temperature and high pressure, sealing device technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of short service life, high maintenance frequency, nitrogen can not fully take away heat, etc., to achieve long service life, safety High, improve the effect of operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

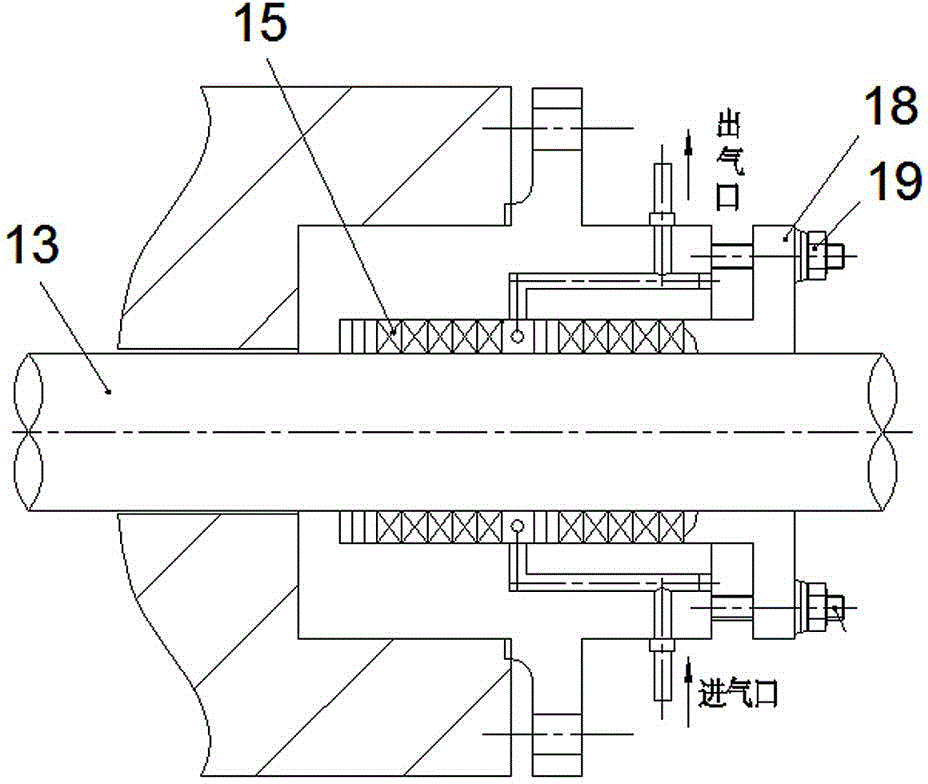

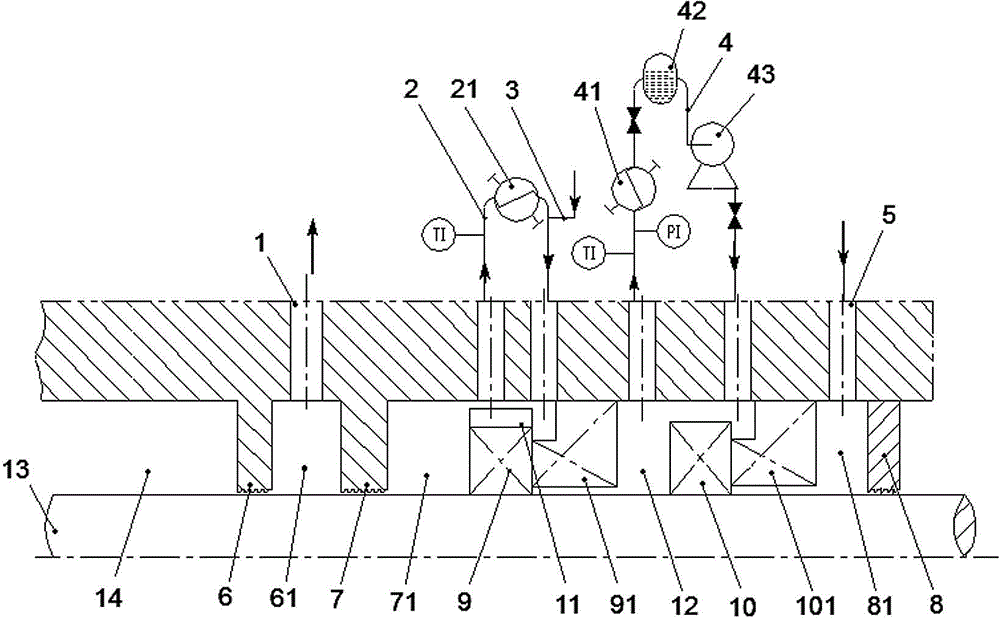

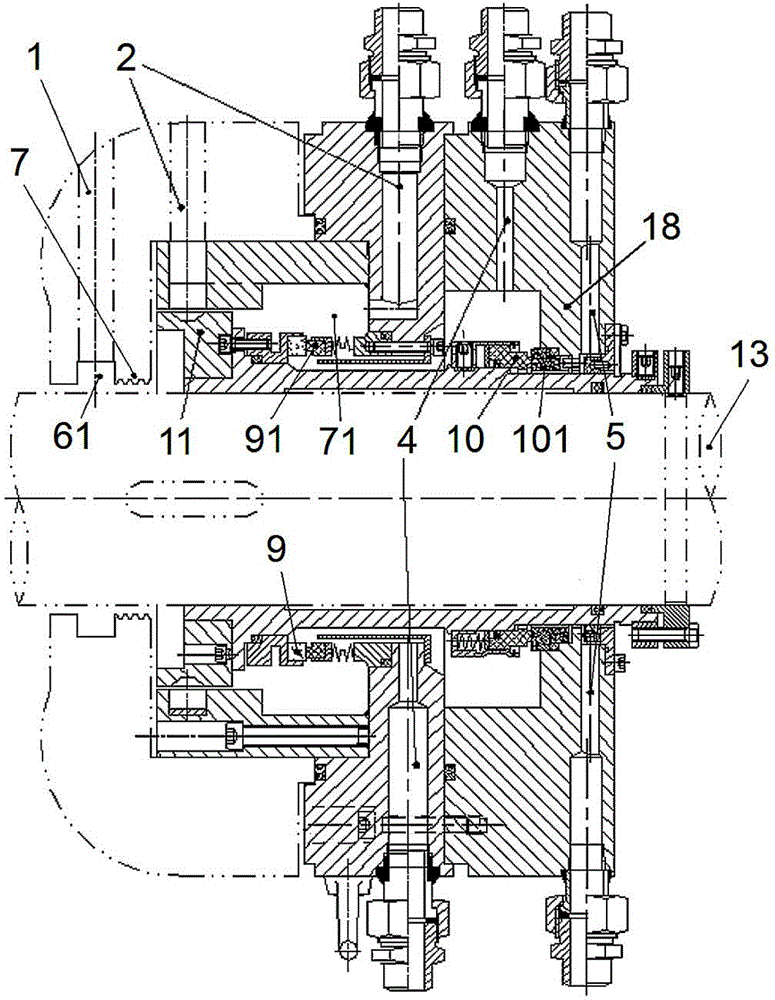

[0024] Such as figure 2 As shown, the sealing device for high-temperature and high-pressure rotary machines of the present invention includes two groups of rotating seal rings and rotary seal rings that are arranged adjacent to each other at the end of the rotating shaft 13 across the high-temperature and high-pressure medium zone 14 in sequence. An end face sealing unit composed of a stationary sealing ring fixedly connected to the base. in:

[0025] ——On the side of the high temperature and high pressure medium area of the first end face sealing unit (ie the main sealing unit) sealed by the metal bellows composed of the first rotating seal ring 9 and the first stationary seal ring 91, there is an adjacent rotary The shaft 13 is spaced apart from a pair of throttling units 6 and 7 to form a depressurization zone 61 . The decompression area 61 can communicate with the high-temperature and high-pressure medium area 14 and the sealing chamber 71 of the first end face sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com