Circulating water cooling device

A heat dissipation device and circulating water technology, applied in lighting devices, cooling/heating devices of lighting devices, lighting and heating equipment, etc., can solve the problems of low heat dissipation efficiency, affecting the light efficiency and life of LED light sources, high temperature of LED light sources and power supplies, etc. problem, to achieve the effect of simple gate valve structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

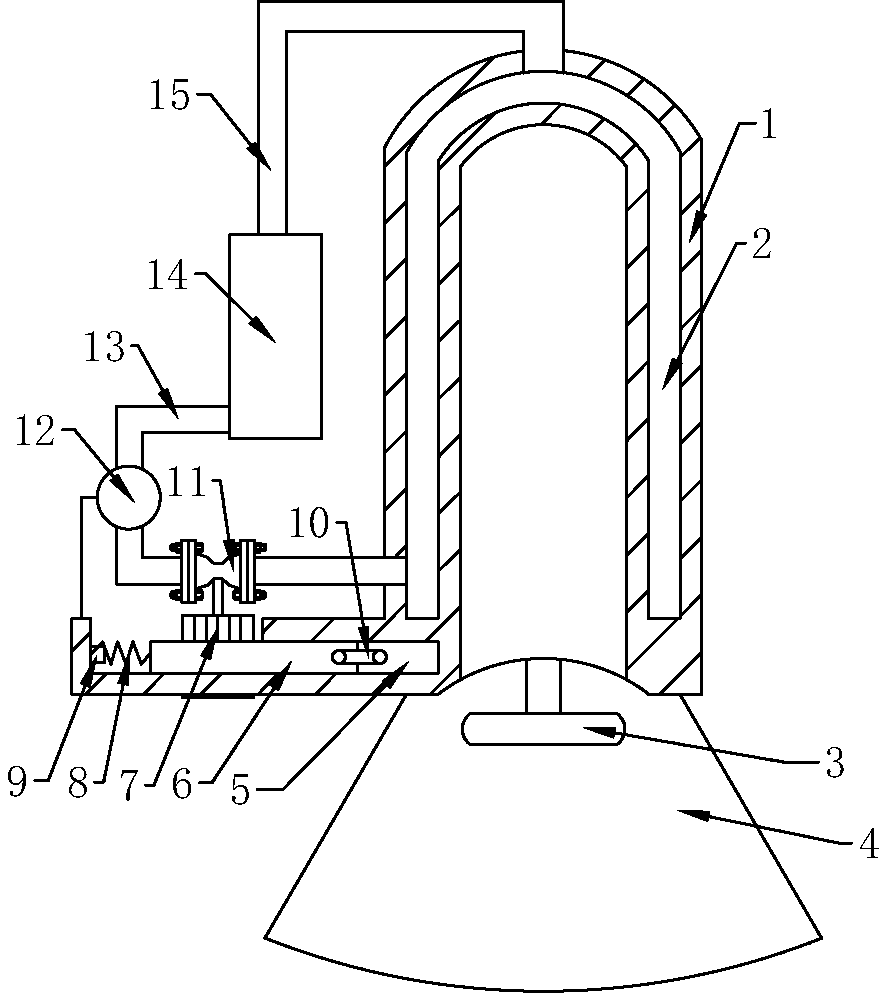

[0016] The reference signs in the drawings of the specification include: heat dissipation cover 1, cavity 2, LED lamp 3, LED lampshade 4, rubber block 5, rack 6, gear 7, spring 8, switch 9, connector 10, gate valve 11, Water pump 12, water inlet pipe 13, cooling box 14, water outlet pipe 15.

[0017] Example basic reference figure 1 Shown: a circulating water type cooling device, including a cooling cover 1, an LED lampshade 4 is fixedly connected under the cooling cover 1, an LED lamp 3 is arranged inside the LED lampshade 4, a cavity 2 is arranged inside the cooling cover 1, and the bottom of the cavity 2 is connected to There is a water inlet pipe 13, an outlet pipe 15 is connected to the upper part of the cavity 2, a cooling box 14 is connected between the water inlet pipe 13 and the water outlet pipe 15, a gate valve 11 is arranged on the water inlet pipe 13, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com