Corrugated expansion joint

A technology of corrugated expansion joints and bellows, which is applied in the field of expansion joints, can solve problems such as the difficulty of cleaning the bellows and polluting the internal environment of the bellows, and achieve the effects of keeping clean, improving the effect, and speeding up the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific embodiments.

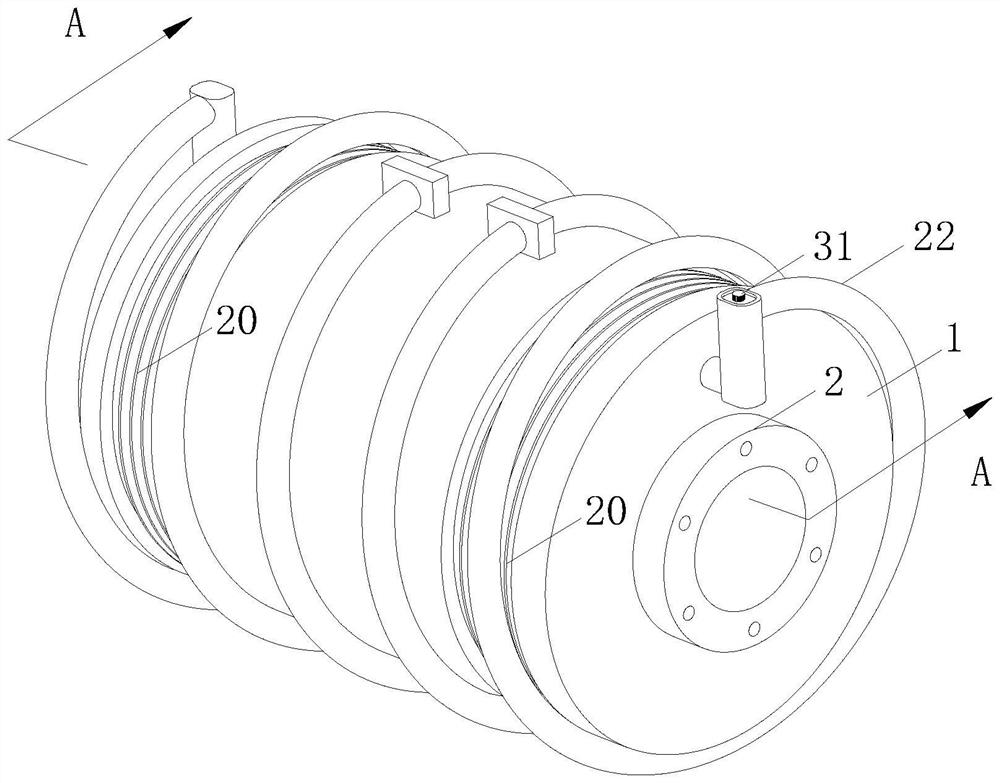

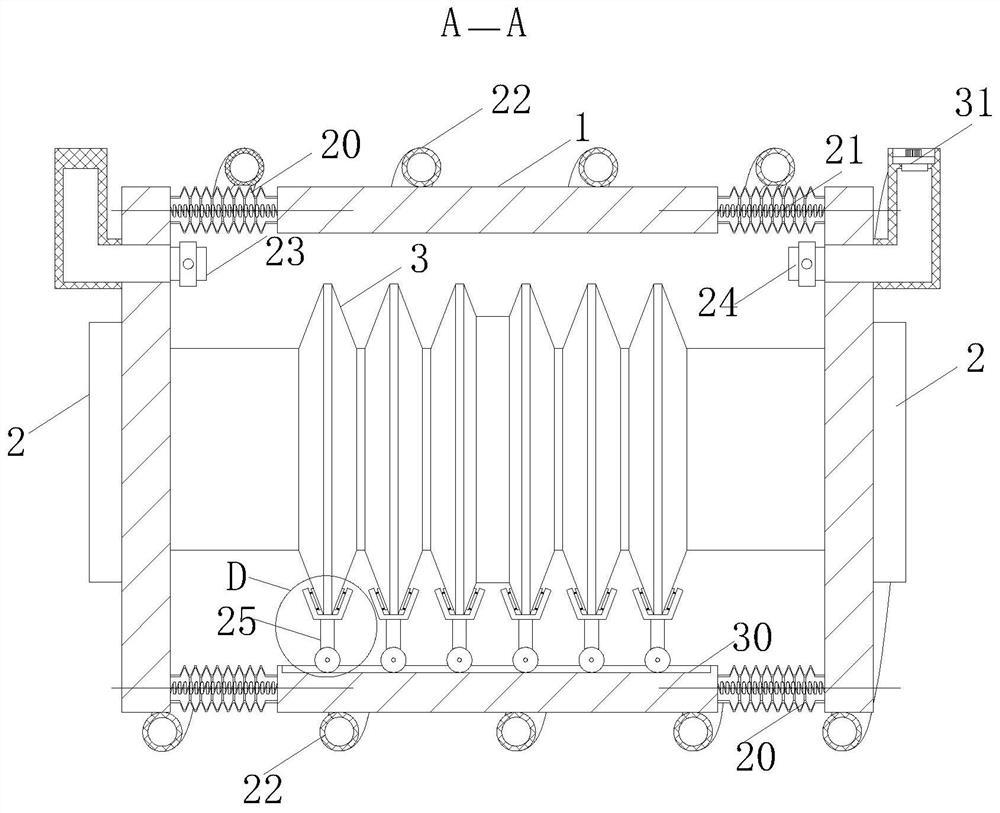

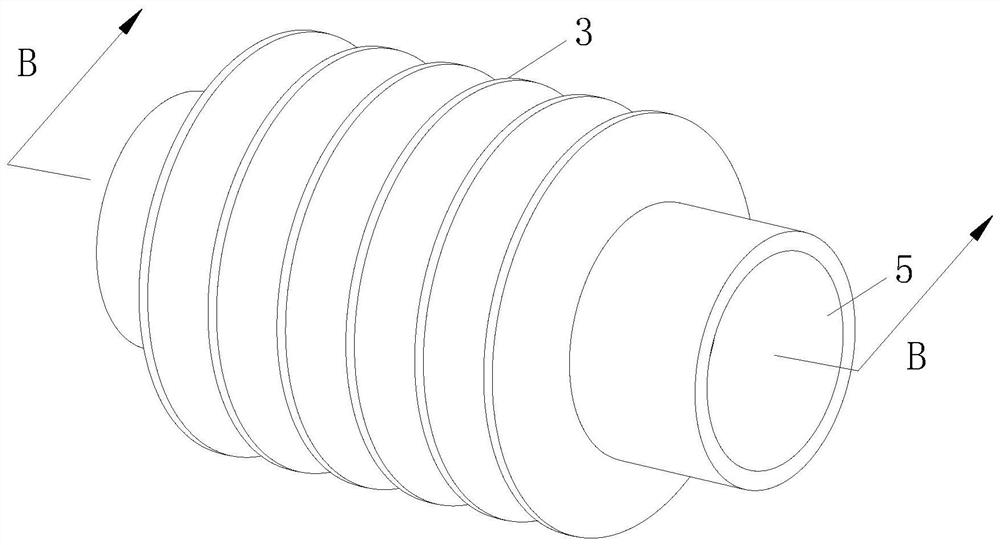

[0025] like Figure 1 - Figure 6 As shown, a corrugated expansion joint according to the present invention includes a protective tube 1, an inner bellows 3, a precipitated drainage mechanism, a water-cooling protection mechanism, and both ends of the protective tube 1 are provided with a mounting disk 2, a protective tube. 1 The internal bellows 3 is fixedly connected between the two mounting plates 2, and the inner bellows 3 is mounted between the inner bellows 3, and the inner bellows 3 and the protective tube 1 are installed with water-cooled protective mechanisms.

[0026] The anti-precipitation drainage mechanism includes an inlet 4, a liquid opening 5, an anti-settling groove 6, a fan sheet 9, and the end of the inner bellows 3 are opened, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com