A calcium sulfate anti-static floor production device

An anti-static floor and production device technology, applied in the field of floor panel production devices, can solve the problems of low work efficiency, uneven heating, high energy consumption, etc., and achieve the effects of increased output and work efficiency, good visual effects, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

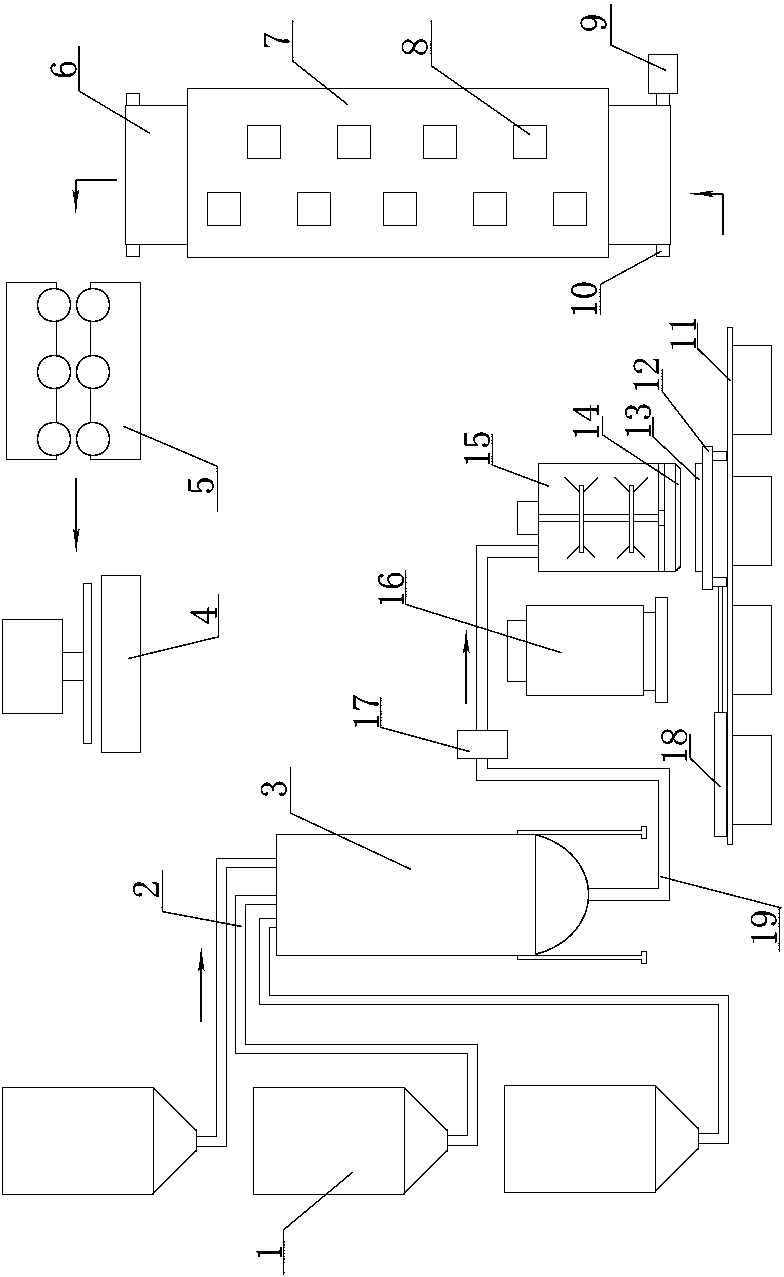

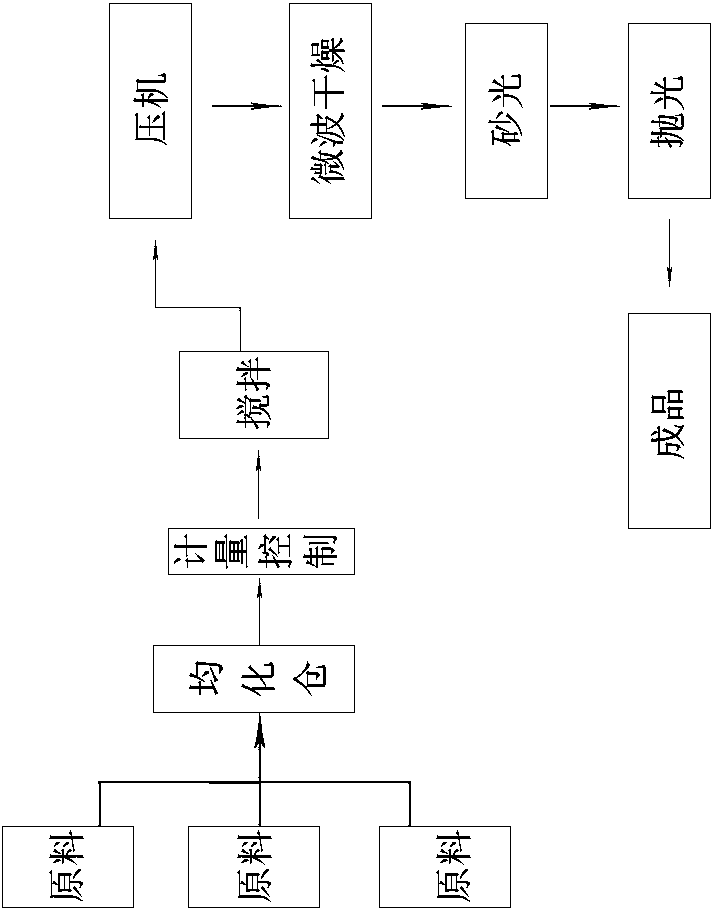

[0019] refer to figure 1 and figure 2 , the present invention includes a homogenization bin 3 communicated with the raw material tank 1 through a pipeline 2; The tops of the mixing tank 15 are connected to each other; the bottom of the stirring tank 15 is provided with a discharge port 14, and the discharge port 14 is provided with a baffle plate that is slidingly connected to each other; Carry out horizontal displacement, and then control the unloading of mixing tank 15; One side of described mixing tank 15 is provided with press 16, and just below pressing machine 16 and mixing tank 15 is provided with its corresponding pushing slideway 11; A slide plate 12 is provided on the pushing slideway 11, and the slide plate 12 promotes horizontal displacement through an oil cylinder 18 at one end of the pushing slideway 11; The other end of described material pushing slideway 11 is provided with microwave heating box 7 with microwave generator 8, and the front end of conveyer bel...

Embodiment 2

[0023] A box body of a microwave heating box, which is prepared according to the following process:

[0024] Step 1) Put the vermiculite, montmorillonite, sepiolite and kaolinite into the crusher for crushing, and then put them into the ball mill tank for ball milling until the particle size is 20 microns, take out the ball mill and place it in a centrifugal mixer In, stir 3 minutes with the stirring speed of 500 revs / min, obtain mixed powder; Wherein, the weight ratio of vermiculite, montmorillonite, sepiolite and kaolinite is 3:2:2:1;

[0025] Step 2) Mix and stir nano-alumina and nano-silicon carbide evenly, and then disperse them in deionized water to prepare an emulsion colloid; wherein, the weight ratio of nano-alumina, nano-silicon carbide and deionized water is 2:1:7;

[0026] Step 3) Put the mixed powder, boron oxide and glass fiber in step 1) into the emulsion colloid in step 2) in sequence, and stir evenly to prepare a ceramic material; wherein, the weight of the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com