a heat absorbing system

A technology of the first fluid and liquid channel, which is applied in lighting and heating equipment, cooling fluid circulation devices, household appliances, etc., and can solve problems such as power consumption, liquid waste, and large load of sewage pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

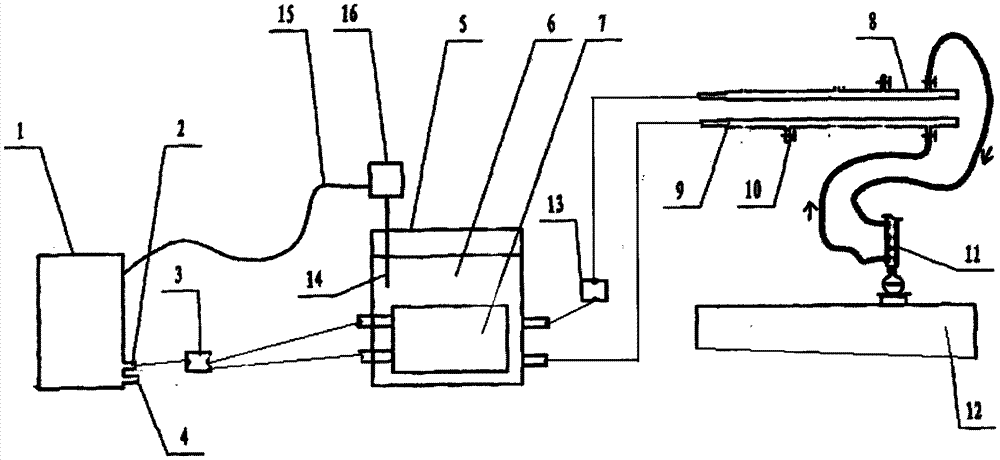

[0010] Below in conjunction with accompanying drawing, content of the invention is described further:

[0011] refer to figure 1 As shown, it includes a first liquid passage 8, a second liquid passage 9, a cooler 1, a first fluid driver 3 and a second fluid driver 13, the fluid outlet 2 of the cooler 1 and the fluid of the first fluid driver 3 The introduction end is connected, and the pipe diameter of described first liquid channel 8 is larger than the pipe diameter of second liquid channel 9, and described second liquid channel 9 and first liquid channel 8 are all hollow rods, and the second liquid Both the channel 9 and the first liquid channel 8 have some fluid channels 10 with valves, and also have a container 5 for storing liquid. The thermal energy induction switch 16 includes an induction component 14, and the induction component 14 of the thermal energy induction switch 16 is the same as The outer walls of the container 5 are in contact, and the wires of the cooler 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap