Design method of a brushless DC motor vibration detection system

A brushed DC motor and vibration detection technology, applied in the field of methods and tests, can solve the problems of inability to guarantee product safety, aggravated jitter, waste of resources, etc., and achieve the effect of great practicability, generalizability, and efficient detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

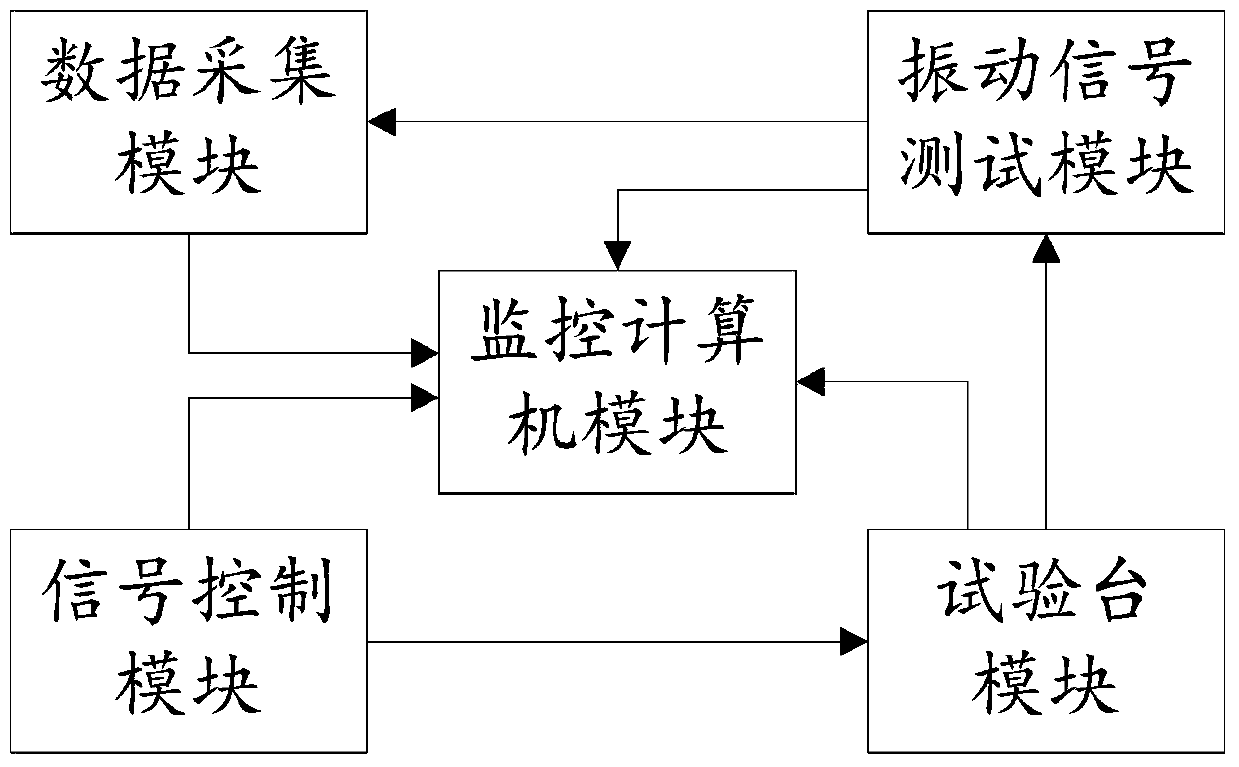

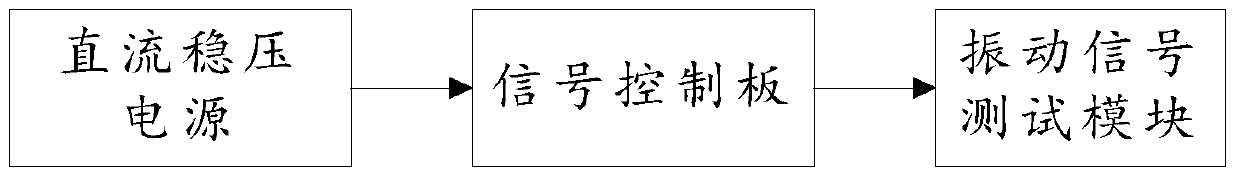

Method used

Image

Examples

Embodiment

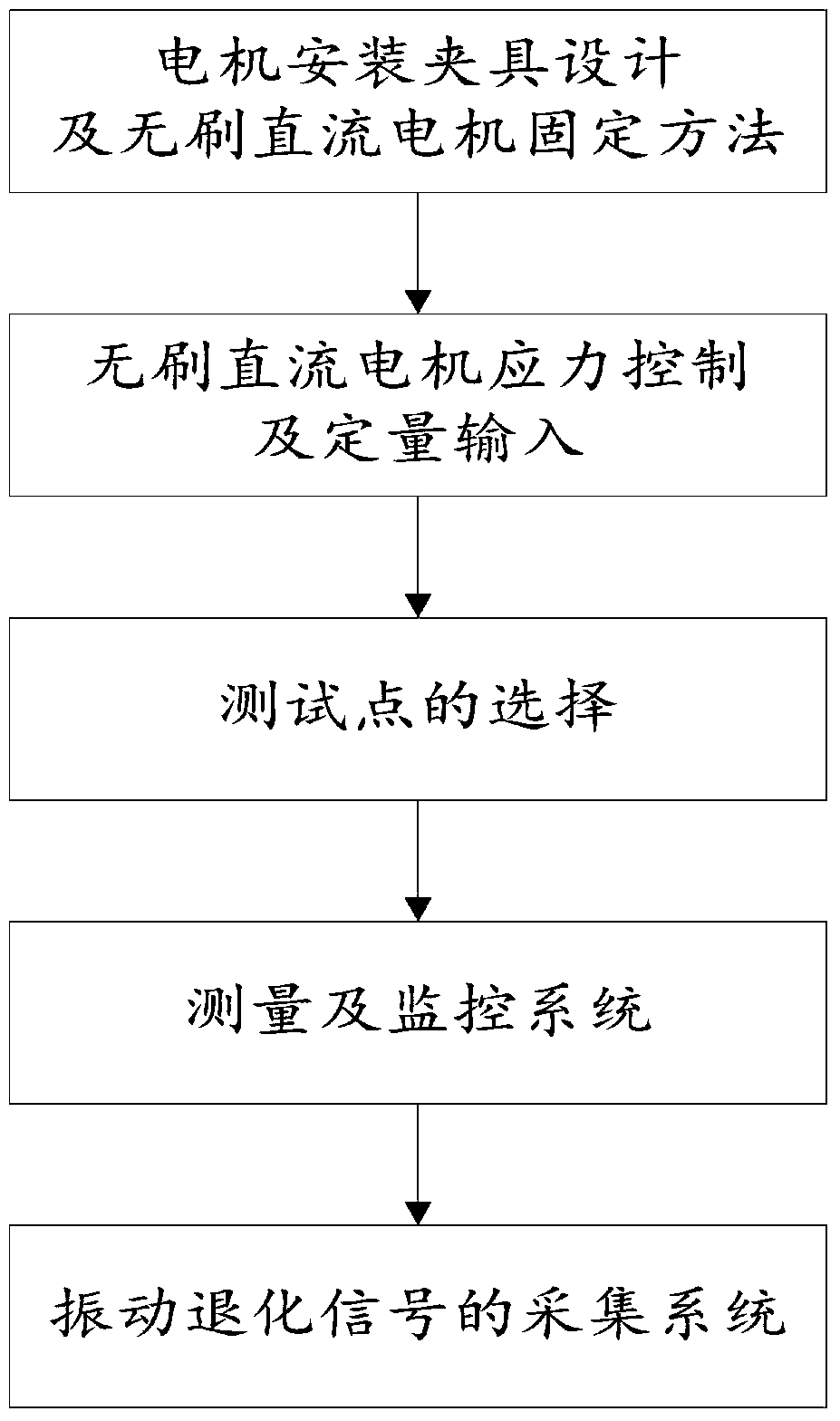

[0051] A certain type of brushless DC motor needs fault detection and life prediction to better carry out reliability assessment and safety prevention work. Now use the method proposed by the present invention to carry out corresponding tests to obtain the vibration signal degradation data of the brushless DC motor.

[0052] Step 1. Fixing method of test fixture and brushless DC motor

[0053] 1) Test fixture

[0054] According to the parameters and specifications of this type of brushless DC motor, the maximum pulling force generated by running with paddles is 20N, so in order to ensure the stability of the test bench during the test and avoid the motor pulling force from interfering with the vibration signal, the weight of the fixture should be much greater than 20N. In addition, the length of the blade of this model is 700mm, so in order to facilitate the placement of sensors, the fixture can be designed as an "I" shape, and the length of the fixture should be greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com