Device and method for fabric camber test that simulates actual wearing

A test method and fabric technology, applied in textile testing, material inspection products, etc., can solve problems such as gaps and can not truly reflect fabric arching, and achieve good repeatability, labor saving, and good simulation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

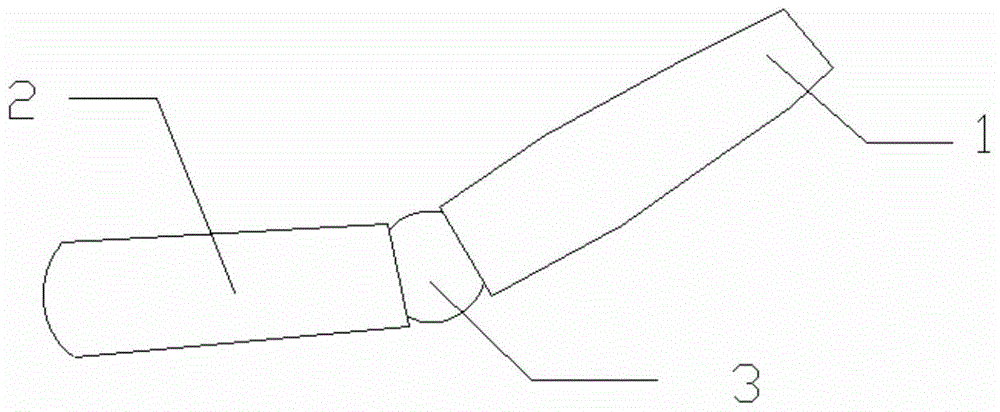

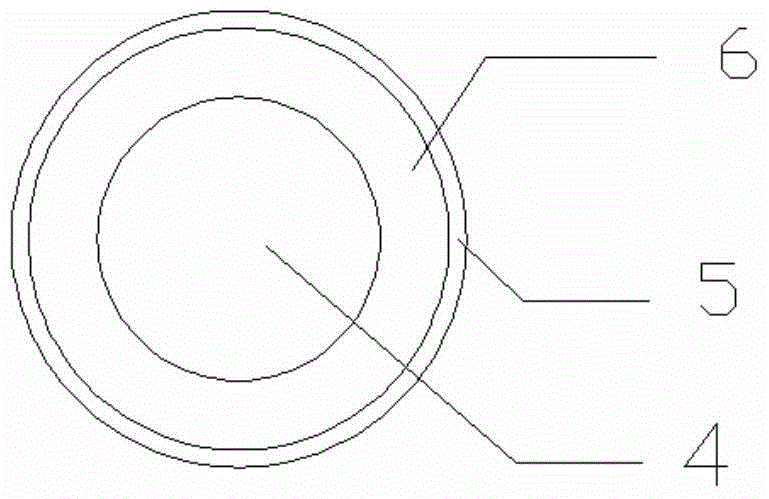

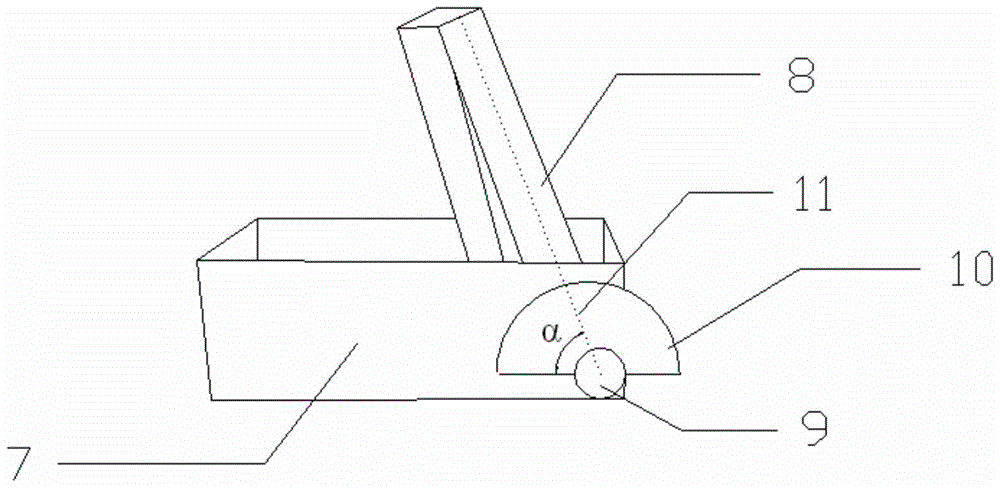

[0026] Such as figure 1 As shown, the test device for fabric camber that simulates actual clothing includes a joint simulation device and a bending fixation device. The joint simulation device is composed of a simulated arm 4, cotton 6 and knitted fabric 5; the simulated arm 4 is composed of a front wooden stick 1, a rear wooden stick 2, a spring and a wooden ball 3; 17cm, the outer perimeter of the thin end is 16cm, simulating the human arm; the front wooden stick 1 is 12cm long, the outer perimeter of the thick end is 16cm, and the outer perimeter of the thin end is 15cm, simulating the forearm of the human body. The thick end of the front stick 1 and the thin end of the back stick 2 are provided with arc grooves; the ball 3 and the spring connect the arc grooves of the front stick 1 and the back sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com