A kind of anti-blue light lens and preparation method thereof

An anti-blue light and lens technology, which is applied in the field of optical lenses, can solve problems such as object color display distortion, and achieve good blue light absorption performance and excellent anti-blue light performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

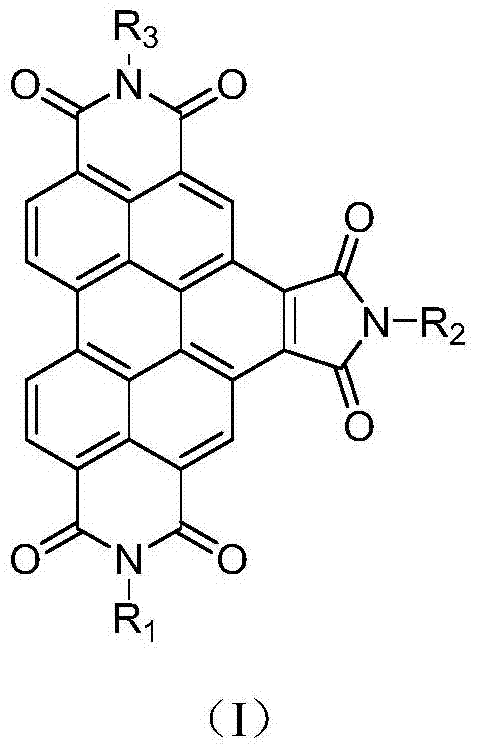

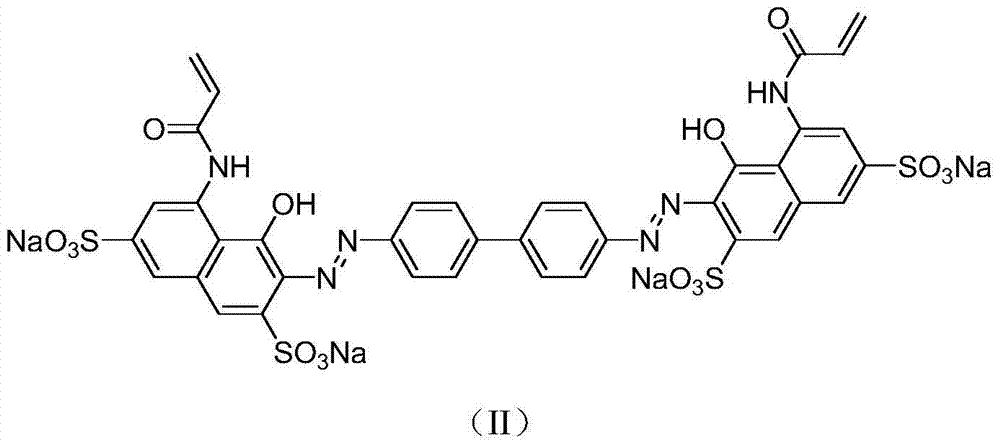

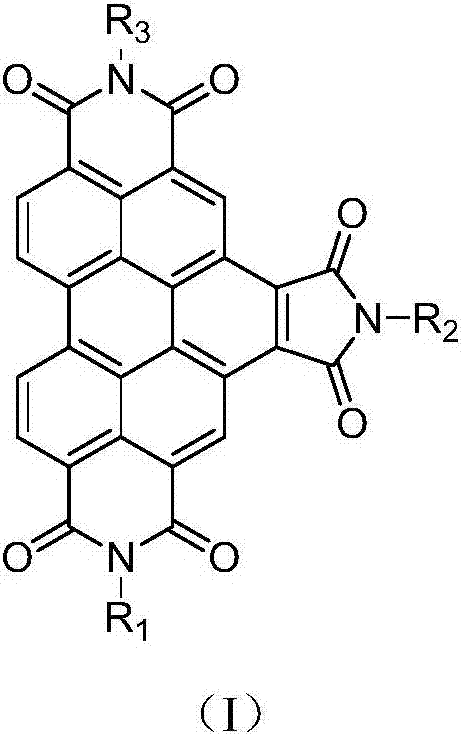

[0023] (1) Mix the raw material polymer polymethyl methacrylate, blue light absorber (molar ratio A:B=1:2) and ultraviolet absorber (mass ratio UV-31:UV-329=1:1) , and stir until the raw materials are evenly mixed; wherein the mass ratio of each component is 98% of high molecular polymer, 0.1% of blue light absorber, and 1.9% of ultraviolet absorber. R in Compound A 1 , R 2 and R 3 Respectively H, methyl, isopropyl.

[0024] (2) Heat and melt the uniformly mixed raw materials, and then pour them into a production mold for solidification and molding to obtain the optical lens 1 .

Embodiment 2

[0026] (1) Mix the raw material polymer polymethyl methacrylate, blue light absorber (molar ratio A:B=1:1) and ultraviolet absorber (mass ratio UV-31:UV-329=1:1) , and stir until the raw materials are evenly mixed; wherein the mass ratio of each component is 98% of high molecular polymer, 0.5% of blue light absorber, and 1.5% of ultraviolet absorber. R in Compound A 1 , R 2 and R 3 Respectively methyl, methyl, isopropyl.

[0027] (2) Heat and melt the uniformly mixed raw materials, and then pour them into a production mold for solidification and molding to obtain the optical lens 2 .

Embodiment 3

[0029] (1) Mix the raw material polymer polymethyl methacrylate, blue light absorber (molar ratio A:B=3:2) and ultraviolet absorber (mass ratio UV-75:UV-928=1:1) , and stir until the raw materials are evenly mixed; the mass ratio of each component is 96% of high molecular polymer, 2% of blue light absorber, and 2% of ultraviolet absorber. R in Compound A 1 , R 2 and R 3 Respectively methyl, tert-butyl, isopropyl.

[0030] (2) Heat and melt the uniformly mixed raw materials, and then pour them into a production mold for solidification and molding to obtain the optical lens 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com