Macroscopic inspection machine capable of automatically positioning and measuring luminance

An automatic positioning and macro inspection technology, applied in the field of macro inspection machines, can solve problems such as potential safety hazards, inability to locate, and contamination of glass substrates, and achieve the effects of increased speed, fast illumination testing, and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

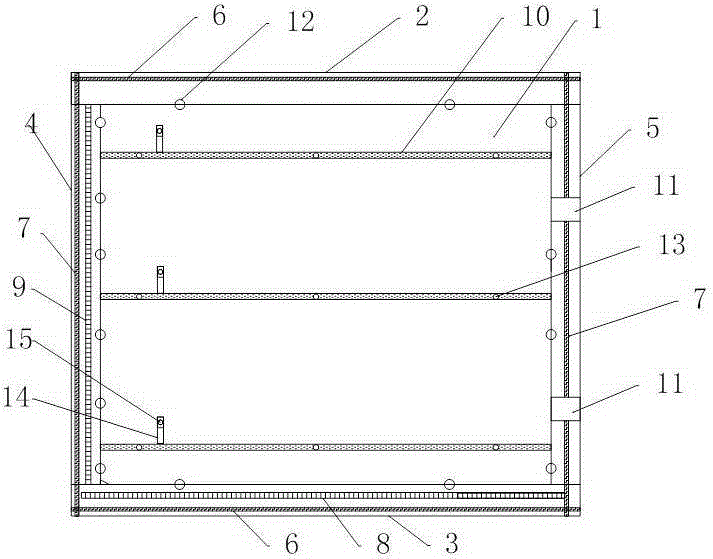

[0027] Such as figure 1 As shown, a macro-inspection machine that can automatically position and measure illuminance includes a machine table for carrying glass and a support rod, and a vacuum suction cup arranged on the support rod for absorbing glass is arranged inside the machine table for The clamp for clamping the glass and the workbench for operating the machine are characterized in that the machine is a frame composed of a first horizontal plane, a second horizontal plane, a first vertical plane, and a second vertical plane. A horizontal scale is installed on the first horizontal surface, a vertical scale is installed on the first vertical surface, and the first vertical surface and the second vertical surface of the water are provided with the first horizontal scale for moving the horizontal scale along the vertical direction. A guide rail, the first horizontal plane and the second horizontal plane are provided with a second guide rail for the vertical scale to move in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com