Ferrograph making oil flow speed control system

A flow rate control and oil technology, which is applied in the direction of control/regulation system, non-electric variable control, and simultaneous control of multiple variables, etc., can solve the problems of changing action time, insensitive response, flow rate fluctuations, etc., and achieve the goal of reducing fluctuations Range, solve the effect of output instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

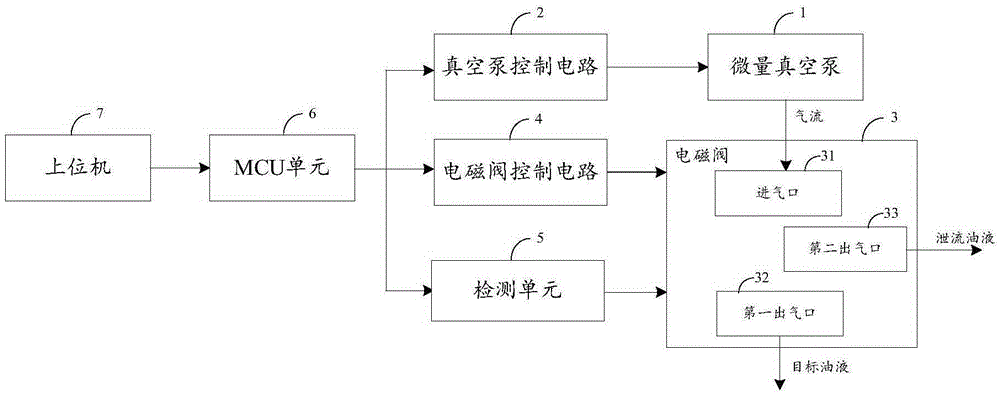

[0034] Such as figure 1 As shown, the ferrographic production oil flow rate control system includes a micro vacuum pump 1, a vacuum pump control circuit 2, a solenoid valve 3, a solenoid valve control circuit 4, a detection unit 5, an MCU unit 6, and a host computer 7, wherein:

[0035] The micro vacuum pump 1 is connected with the MCU unit 6 through the vacuum pump control circuit 2 as an oil source; the solenoid valve 3 is connected with the MCU unit 6 through the solenoid valve control circuit 4 to receive the control signal of the MCU unit 6, and the solenoid valve 3 is also connected with the micro The vacuum pump 1 is connected, and the oil source is shunted through the control signal; the detection unit 5 is respectively connected with the solenoid valve 3 and the MCU unit 6, and is used to detect the oil information of the solenoid valve 3, and transmit the detection result to the MCU unit 6 , can feed back the oil information of the solenoid valve 3 to the MCU unit 6 ...

Embodiment 2

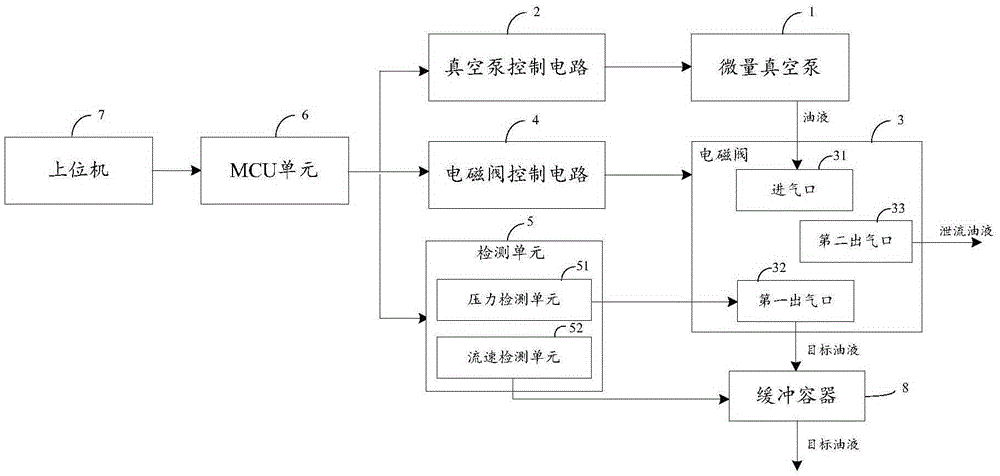

[0042] Such as figure 2 As shown, the ferrography production oil flow rate control system includes a micro vacuum pump 1, a vacuum pump control circuit 2, a solenoid valve 3, a solenoid valve control circuit 4, a detection unit 5, an MCU unit 6 and a host computer 7.

[0043] In this embodiment, on the basis of embodiment 1, a buffer container 8, a pressure detection unit 51 and a flow rate detection unit 52 are added, and the same parts as those in the embodiment are not repeated here.

[0044] Further, the oil flow rate control system for ferrography further includes a buffer container 8 connected to the first air outlet 32 for buffering and outputting the target oil. The use of the buffer container 8 makes it easier for the electromagnetic valve 3 to adjust the fluctuation range.

[0045]Further, the detection unit 5 includes: a pressure detection unit 51 and a flow rate detection unit 52, the pressure detection unit 51 is respectively connected with the first air outle...

Embodiment 3

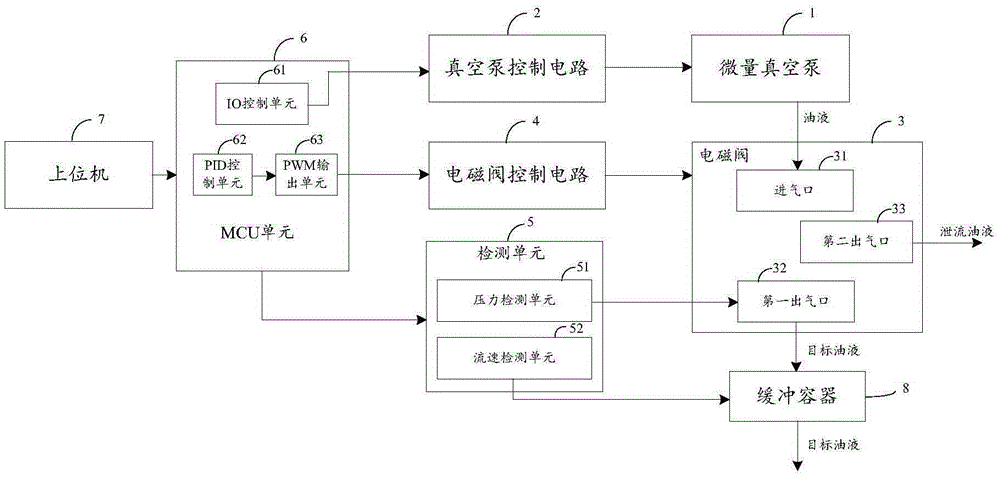

[0049] Such as image 3 As shown, the oil flow rate control system for ferrography production includes micro vacuum pump 1, vacuum pump control circuit 2, solenoid valve 3, solenoid valve control circuit 4, detection unit 5, MCU unit 6, host computer 7 and buffer container 8.

[0050] In this embodiment, an IO control unit 61 , a PID control unit 62 and a PWM output unit 63 are added on the basis of Embodiment 2, and the same parts as those in Embodiment 2 will not be repeated here.

[0051] Further, the MCU unit 6 includes: an IO control unit 61 , the IO control unit 61 is connected with the vacuum pump control circuit 2 , and is used to realize the IO control of the micro vacuum pump 1 by the MCU unit 6 .

[0052] Further, the MCU unit 6 also includes a PID control unit 62 and a PWM output unit 63, the PID control unit 62 is connected with the PWM output unit 63 for adjusting the PWM signal output by the PWM output unit 63; the PWM output unit 63 is also connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com