Construction method for collision detection system

A technology of collision detection and construction method, which is applied in the construction field of collision detection system, can solve problems such as poor human-computer interaction, penetration, and non-compliance with assembly requirements, and achieve the effect of easy principle, strong practicability, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

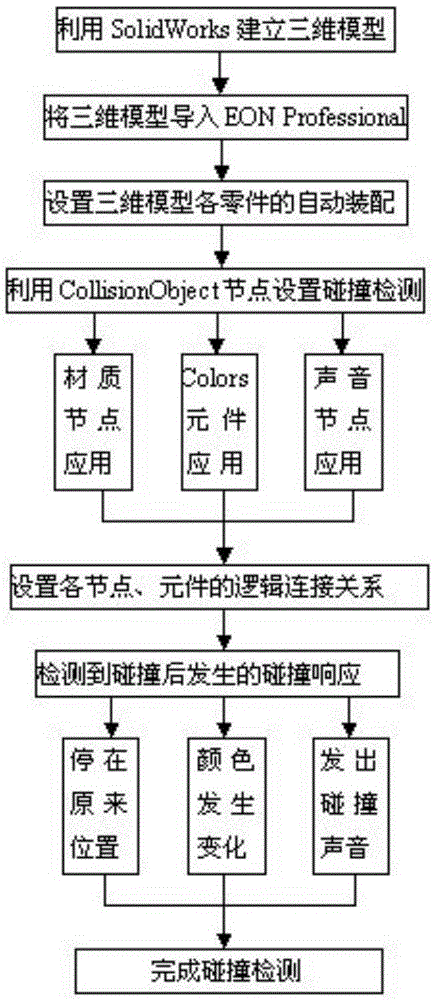

[0029] see figure 1 , a construction method of a collision detection system, the present invention takes the collision detection between the main shaft and the pulley of the CNC lathe headstock as an example, and describes the implementation process of the present invention in detail, including the following steps:

[0030] step one:

[0031] Create a 3D model of the CNC lathe headstock in SolidWorks, and import the built 3D model into EON Professional, the software will automatically assign part nodes to each part of the CNC lathe headstock;

[0032] Step two:

[0033] Set the automatic assembly of the spindle box. This process mainly uses the Place node. Drag the Place node to each part node, double-click the node, and set the part along the X-axis or Y-axis during the automatic assembly process in the pop-up property window. Or the dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com