Solid welding wire gas shield welding method for nickel-based plate type splicing

A technology of solid welding wire and gas shielded welding, which is applied in the direction of welding/welding/cutting items, welding equipment, welding media, etc., can solve the problem of high welding cost, achieve the effect of reducing welding cost, ensuring quality, and ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Take the automatic welding of finned tubes of a gasifier superheater as an example to illustrate:

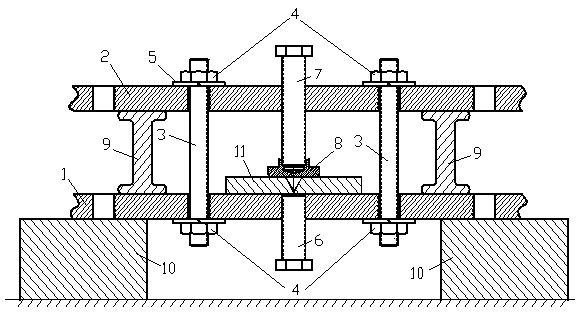

[0046] The finned tube material of the gasifier is SB-407N08800LC, see Image 6 , the length of a single tube is about 6m. During manufacture, 4 or 6 finned tubes are firstly used to splice into a tube panel, and the welding seam at the splicing part is beveled on one side. The specific process is as follows.

[0047] Use the welding staggered edge control tool to assemble 4 or 6 finned tubes into a tube panel, arrange an assembly tool every 1.5m in the length direction of the finned tube, and arrange 5 toolings in total to control the staggered edge of the groove. 0.5mm and below;

[0048] Use manual argon tungsten arc welding spot welding to splice welds, welding wire ERNiCrMo-3φ2.4, current 80A, voltage 14V, spot welding the side without groove first, spot welding 50mm long every 1m, and then turn over the tube screen to spot weld the groove side, 20mm long spot weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap