Machining platform for aircraft hanger intersections

A processing platform and hanging technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as processing errors, assembly errors, and difficulty in further improving product quality, and achieve the effect of ensuring processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

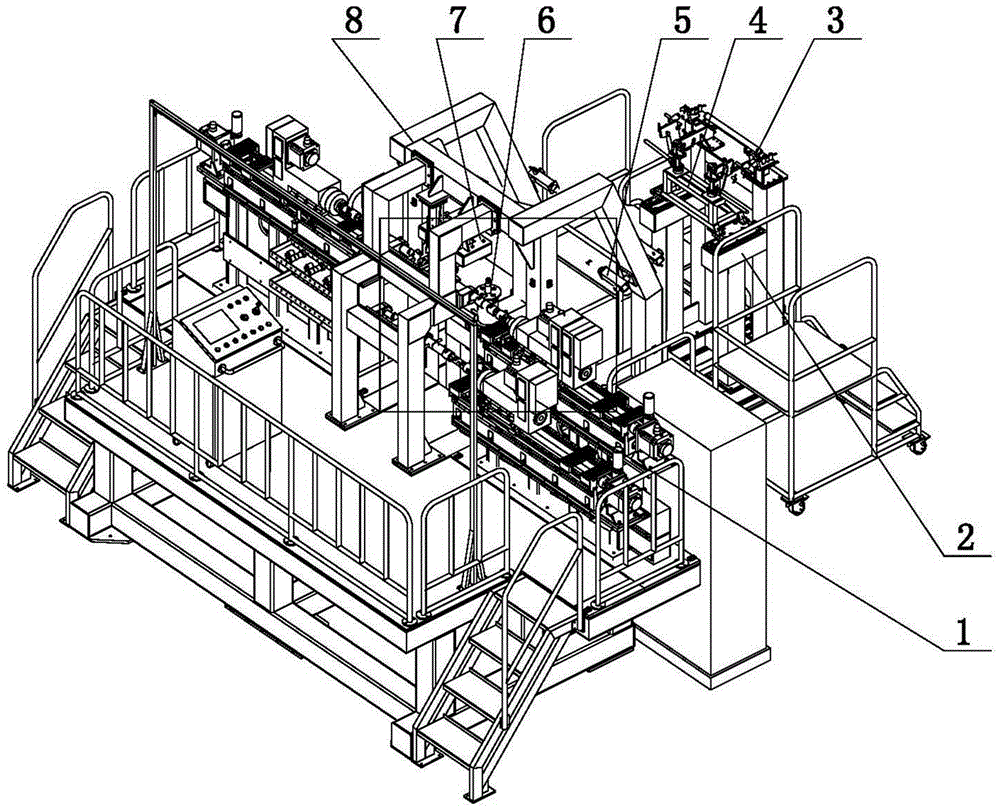

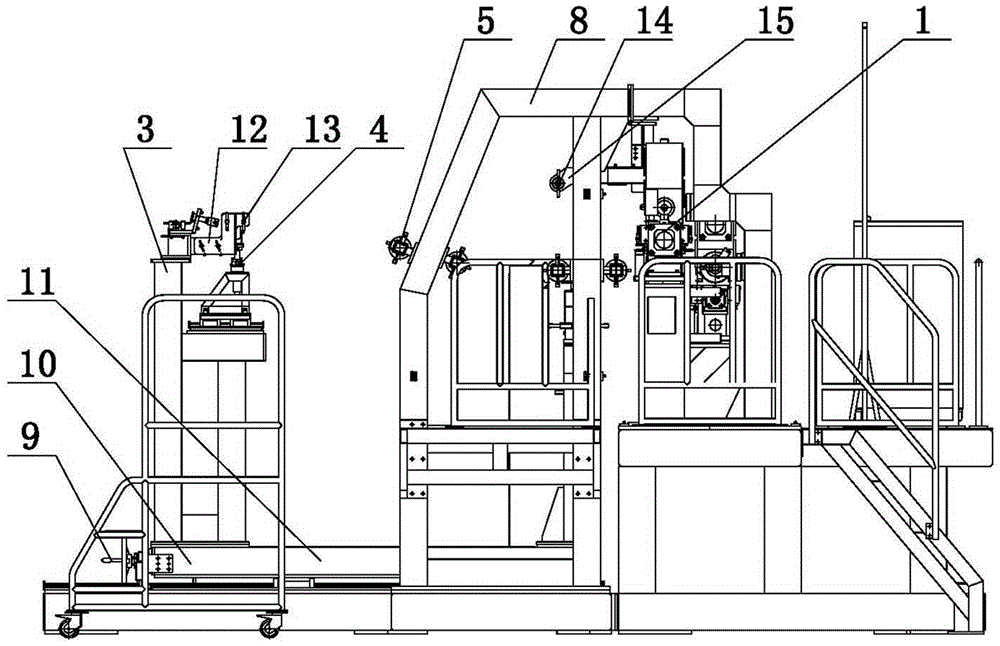

[0014] The present invention includes a frame 8 on which a positioning assembly 2 and a processing bed 1 are arranged. Positioning mechanism 6, middle lifting mechanism 4 and rear positioning mechanism 3; Described processing bed body 1 comprises the feeding device 44 that is arranged on the both sides of movable frame 10; The processing head 43 is arranged on the feeding device 44, and The output spindle of the output spindle is connected with the guide rod 41 through the universal joint 42; the end of the guide rod 41 is provided with a processing tool; The front positioning mechanism 6 is provided with a positioning surface 7 .

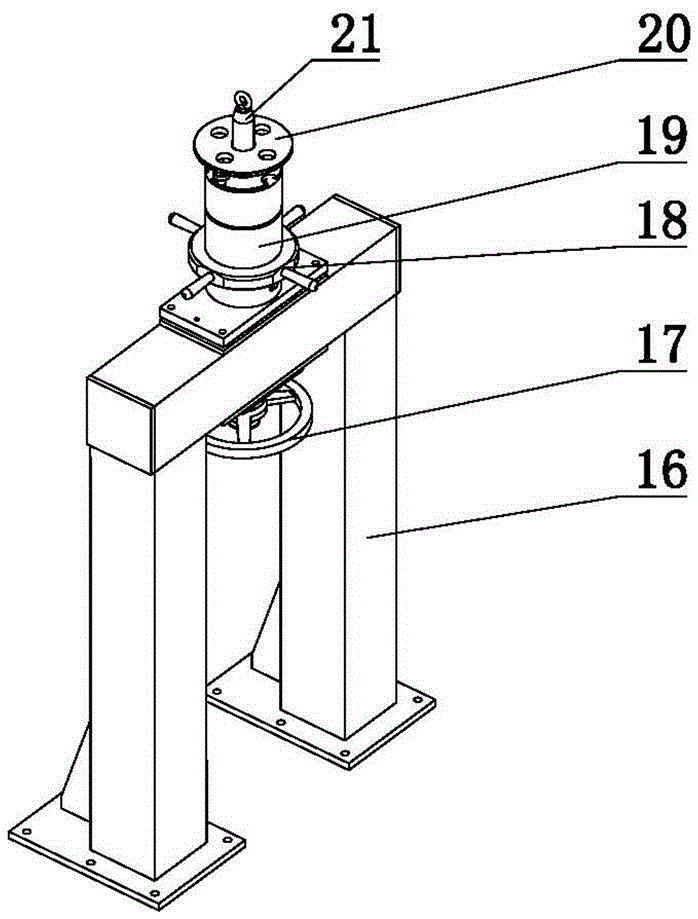

[0015] The front positioning mechanism 6 includes a front positioning frame 16 arranged on the mobile frame 10 , a support plate 20 is provided above the front positioning frame 16 through a first lifting mechanism 19 , and a positioning shaft 21 is arranged on the support plate 20 .

[0016] A first driving handwheel 17 is arranged below the firs...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap