Tool box storing and popping structure

The technology of a toolbox and a main box is applied in the field of toolbox storage and pop-up structure, which can solve the problems of inconvenient carrying, troublesome maintenance, and many tools, and achieves the effect of being convenient to use and not easily lost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

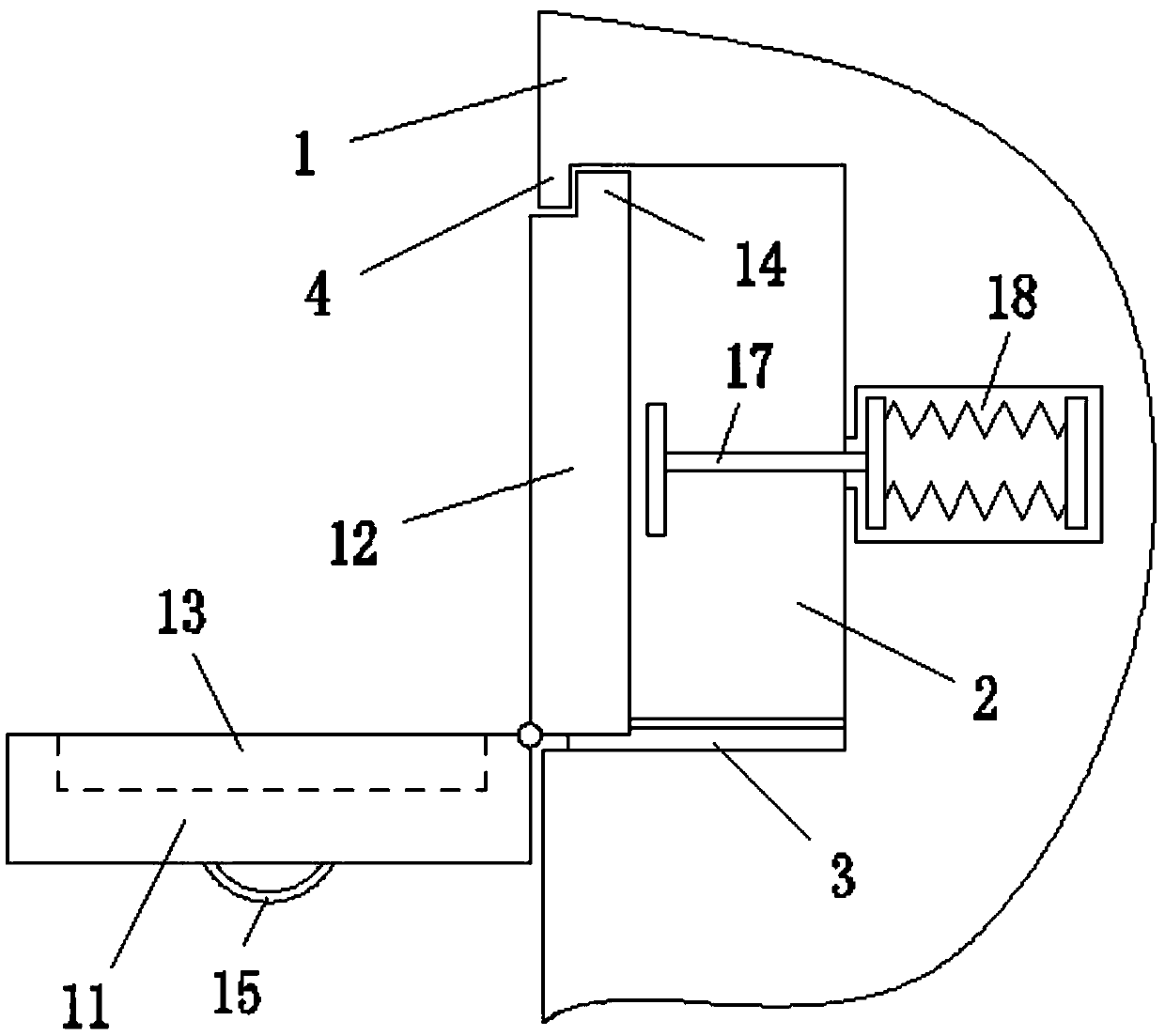

[0011] The present invention is described below in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown, a toolbox storage pop-up structure according to the present invention includes a switch cabinet side wall 1 and a tool box, and a storage space 2 is provided in the switch cabinet side wall 1, and a slide rail 3 and a stopper are provided in the storage space 2 4. The tool box is slidingly matched with the slide rail 3; the tool box includes a main box body 11 and an auxiliary box body 12 hinged to each other, the main box body 11 is provided with a tool storage part 13, and the auxiliary box body 12 is provided with a mating block 14. After the toolbox is closed and stored in the accommodation space 2, the outside of the main box body 11 is flush with the outer surface of the side wall 1 of the switch cabinet. When the toolbox is pulled out to the maximum position, the mating block 14 is matched with the stopper 4 , so that the auxiliary box 12 is lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com