Nail dropping device

A technology for setting nails and installing boards, which is applied in the direction of nailing tools, U-shaped nailing tools, manufacturing tools, etc., which can solve the problems of low efficiency and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

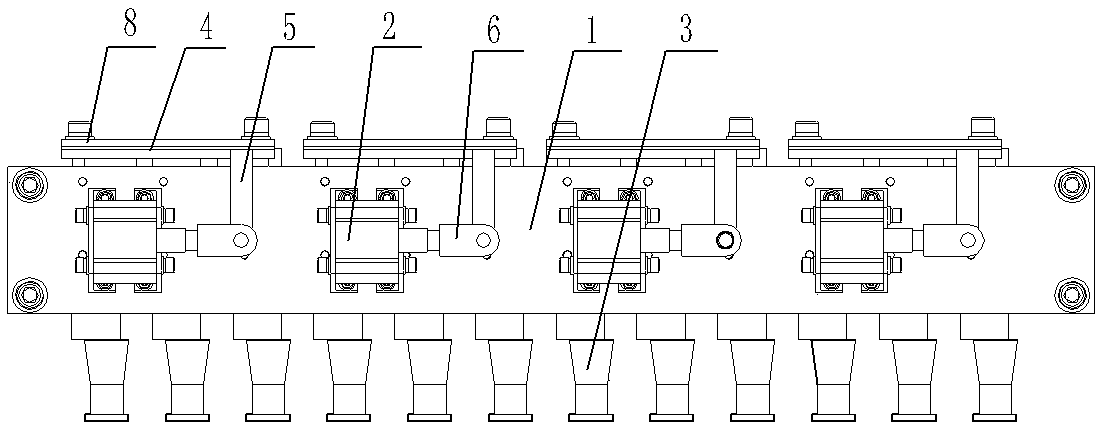

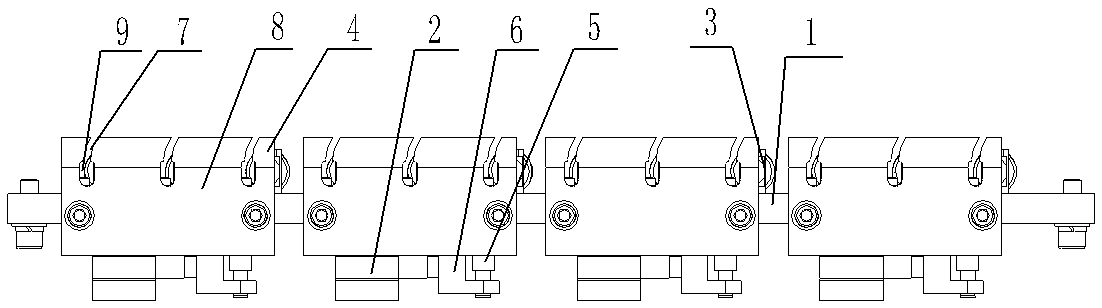

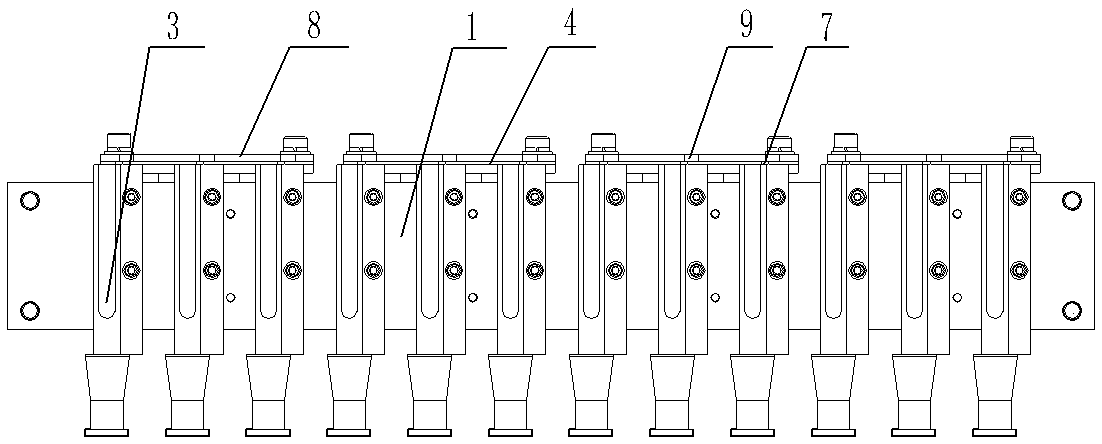

[0016] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a nail setting device includes a push cylinder mounting plate 1, a horizontal drive cylinder 2 is installed on one side of the push cylinder mounting plate 1, a nail guide tube 3 is vertically installed on the other side, and the upper end of the push cylinder mounting plate 1 is set There is a slidable cylinder push plate 4, the cylinder push plate 4 is connected to the double elbow joint 6 installed on the piston rod of the horizontal cylinder 2 through the connecting rod 5, and the cylinder push plate 4 has an opening corresponding to the nozzle of the nail guide tube 3 Slot 7.

[0017] Three open slots 7 are evenly opened on the cylinder push plate 4, and the lower end of each open slot 7 is provided with a nail guide tube 3, and a cylinder push plate 4 and a horizontal drive cylinder 2 form a guide nail mechanism, and the push cylinder installation plate 1 is set There are four nail guide me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com