A cutting knife wheel for fragile materials

A technology of brittle materials and cutting knives, which is applied in glass cutting devices, stone processing tools, stone processing equipment, etc., can solve problems such as inability to effectively control glass bifurcations, disc knives are difficult to cut into the glass, and avoid glass The effect of bifurcation and splitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

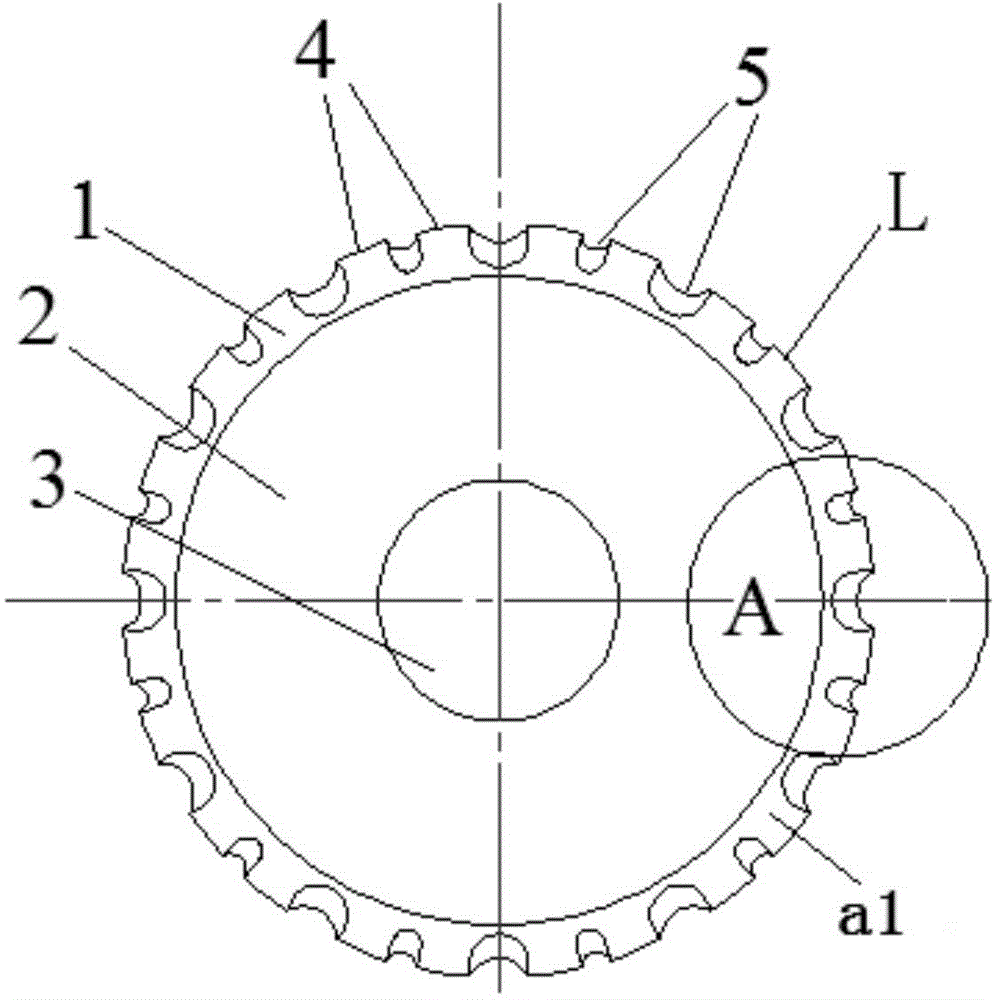

[0064] The first specific embodiment (the first cutter wheel):

[0065] As shown in Fig. 1 (a), Fig. 1 (b), and Fig. 1 (c), the first cutting wheel includes two kinds of concave structures 5 with different sizes, which are respectively the first concave structure 51 and the second concave structure 52 The bottoms of the first concave structure 51 and the second concave structure 52 are both provided with a V-shaped cutting edge 8 formed by the first concave surface 6 , the second concave surface 7 and the curved section. The first recessed structures 51 and the second recessed structures 52 are alternately arranged at intervals. Among them, the first concave structure 51 and the second concave structure 52 can be connected by a smooth transition of a circular arc between the position close to the circular disk surface 2 and the first curved surface a1 and the second curved surface a2; and the first concave structure 51 and The junction between the second concave structure 52 ...

no. 2 Embodiment

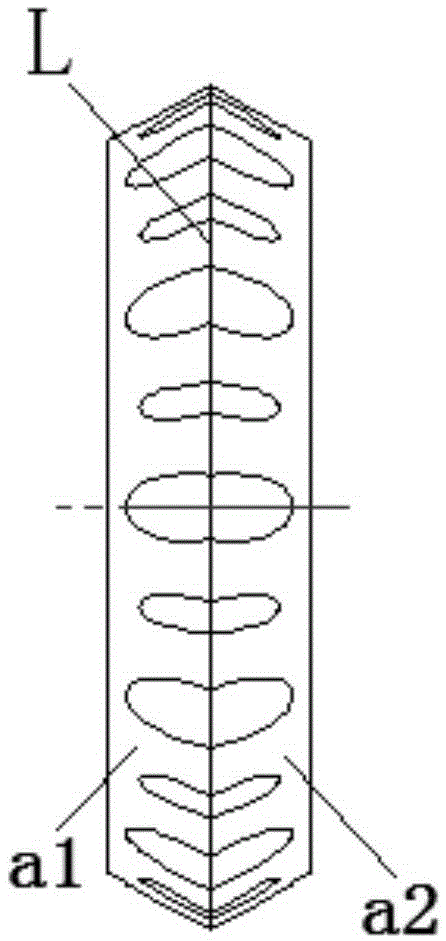

[0067] The second specific embodiment (the second cutter wheel):

[0068] As shown in Fig. 2 (a), Fig. 2 (b), at least one third curved surface a3 can also be provided between one side of the outer edge ridge line L of the second cutting wheel and the first curved surface a1, and the outer edge edge At least one fourth curved surface a4 may also be provided between the other side of the line L and the second curved surface a2.

no. 3 Embodiment

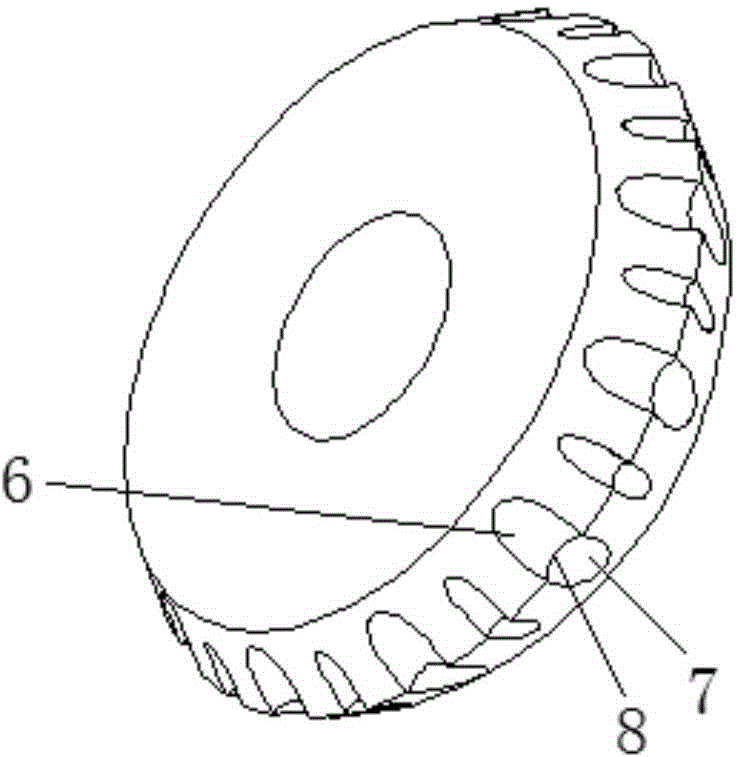

[0069] The third specific embodiment (the third cutter wheel):

[0070] As shown in Fig. 3(a) and Fig. 3(b), the third cutting wheel has several different types of concave structures 5, for example. Except the concave structure 5 that is provided with on the first cutter wheel, also have the concave structure 5 of multiple shapes such as trapezoid, inverted trapezoid, triangle and circular arc, not describe one by one here, and the concave structure of various shapes and sizes 5 can be provided with a V-shaped cutting edge 8, and those of ordinary skill in the art should understand that the size changes, structural changes, opening size changes, and bottom changes of the recessed structure 5 should all be covered by the scope of the technical solution claimed by the present invention. among.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com