Door plate hoisting transfer device

A transfer device and hoisting technology, which is applied in the direction of transportation and packaging, trolley cranes, cranes, etc., can solve the problems of extrusion processing space, large transportation space, and defective products, so as to save transportation space, ensure safety, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

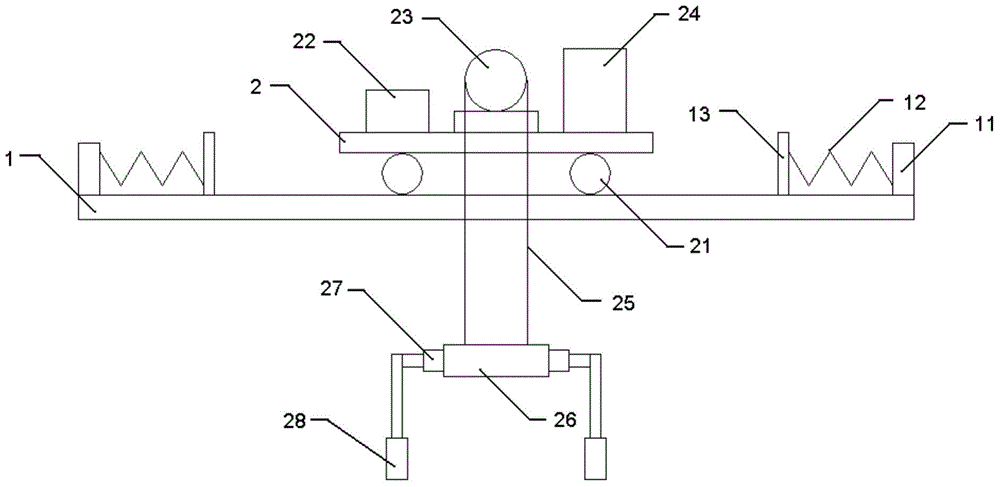

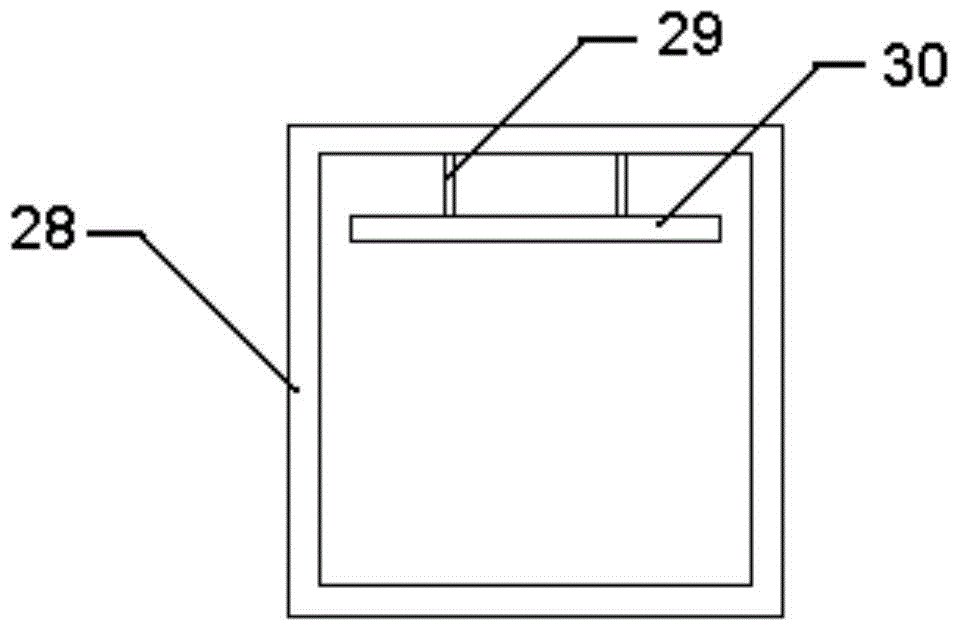

[0015] Such as figure 1 with figure 2 A door panel hoisting transfer device, comprising a guide rail 1 and a truck 2, both ends of the guide rail 1 are provided with stoppers 11; the opposite sides of the two stoppers 11 are provided with springs 12; any of the springs 12 is also connected with the speed brake 13; the guide rail 1 and the truck 2 are connected through the wheels 21 arranged at the bottom of the truck 2; the top of the truck 2 is provided with a driving motor 22, a lift 23 and a controller 24; the lift 23 is connected with steel cable 25; The end of described steel cable 25 is provided with elevating platform 26; The two ends of described elevating platform 26 are all provided with telescoping rod 27; All are provided with chuck 28 on any described telescopic rod 27; The upper part of the chuck 28 is provided with a hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com