Method for evaluating structuralization of methyl vinyl silicone rubber product

A methyl vinyl silicon, product structure technology, applied in the direction of instruments, analytical materials, flow characteristics, etc., can solve the problems of increasing labor intensity, reducing production efficiency, unable to understand product quality in advance, etc. Evaluate quickly and evaluate immediate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

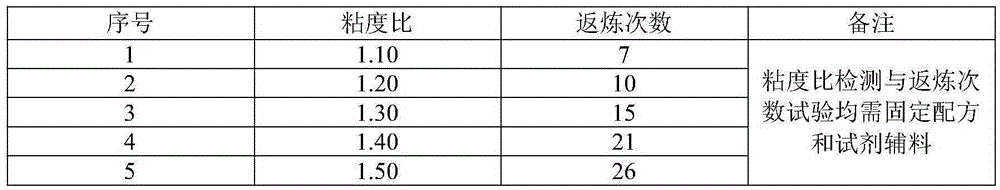

Embodiment 1

[0027] Pour 500 grams of DMC into a 1000ml beaker, weigh 50 grams of raw rubber sample A on aluminum foil, cut the raw rubber into small pieces, add it to DMC to dissolve, fix the sample cup under the stirrer, stir for 4 hours, and dissolve completely . Then take 250ml of the solution and pour it into a disposable water cup, place it in a 25°C incubator for 2 hours, set the Brookfield rotor viscometer speed at 20RPM, select the No. 2 rotor, test the viscosity of 309.6mPa.s, and then add 0.25g Vinyltrimethoxysilane and 0.15 g of dibutyltin dilaurate were sealed and stirred evenly, and placed in a thermostat at 25° C. for 1 hour. The viscosity was tested again to be 396.4 mPa.s, and the gelation viscosity ratio was 1.28. Mix 140g of raw rubber B, 70g of white carbon black, and 4.2g of hydroxy silicone oil on an open mill for 15 minutes, then heat-treat at 190°C for 3 hours, cool for 20 hours, and re-mill. The number of re-milling of this raw rubber is 14 times.

Embodiment 2

[0029] Pour 500 grams of DMC into a 1000ml beaker, weigh 25 grams of raw rubber sample A on aluminum foil, cut the raw rubber into small pieces, add it to DMC to dissolve, fix the sample cup under the stirrer, stir for 4 hours, and dissolve completely . Then take 250 ml of the solution and pour it into a disposable water cup, place it in a 25°C incubator for 2 hours, set the speed of Brookfield viscometer at 20RPM, select the No. 2 rotor, test the viscosity of 165.0mPa.s, and then add 0.25g Vinyltrimethoxysilane and 0.15 g of dibutyltin dilaurate were sealed and stirred evenly, and placed in a thermostat at 25° C. for 1 hour, and the viscosity was tested again to be 213.0 mPa.s, and the gelation viscosity ratio was 1.29. Mix 140g of raw rubber B, 70g of white carbon black, and 4.2g of hydroxy silicone oil on an open mill for 15 minutes, then heat-treat at 190°C for 3 hours, cool for 20 hours, and re-mill. The number of re-milling of this raw rubber is 14 times.

Embodiment 3

[0031] Pour 500 grams of DMC into a 1000ml beaker, weigh 100 grams of raw rubber sample A on aluminum foil, cut the raw rubber into small pieces, add to DMC to dissolve, fix the sample cup under the stirrer, stir for 4 hours, and dissolve completely . Then take 250 ml of the solution and pour it into a disposable water cup, place it in a 25°C incubator for 2 hours, set the speed of Brookfield viscometer at 20RPM, select the No. 2 rotor, test the viscosity of 388.6mPa.s, and then add 0.25g Vinyltriethoxysilane and 0.15 g of dibutyltin dilaurate were sealed and stirred evenly, and placed in a thermostat at 25°C for 1 hour. The viscosity was tested again to be 493.6 mPa.s, and the gelation viscosity ratio was 1.27. Mix 140g of raw rubber B, 70g of white carbon black, and 4.2g of hydroxy silicone oil on an open mill for 15 minutes, then heat-treat at 190°C for 3 hours, cool for 20 hours, and re-mill. The number of re-milling of this raw rubber is 14 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com