Preparation method of ultra-stable silicone oil-based magnetorheological fluid

A technology of magnetorheological fluid and silicone oil, which is applied in the field of preparation of silicone oil-based magnetorheological fluid, can solve the problems of cumbersome preparation process and achieve the effect of avoiding cumbersome steps and satisfying complex reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing an ultra-stable silicone oil-based magnetorheological fluid, comprising:

[0033] Add magnetically sensitive particles and additives into the carrier liquid, stir and mix, and then carry out compound reaction to obtain oil-based magnetorheological fluid in one step;

[0034] Among them, the proportions of magnetic sensitive particles, carrier liquid and additives are respectively as follows:

[0035] Magnetic sensitive particles: 30-35 parts; carrier liquid: 50-70 parts; additives: 1-10 parts;

[0036] Wherein, the magnetic sensitive particle is Fe 3 0 4 Powder or alloy particle powder of Fe, Co and Ni, the average particle diameter of the magnetic sensitive particles is 1-10 microns;

[0037] The additives include antifriction and antiwear agents, antioxidants, thixotropic agents, antifreeze agents and surfactants;

[0038] The carrier liquid is silicone oil;

[0039] Wherein, the temperature for composite reaction aft...

Embodiment 1

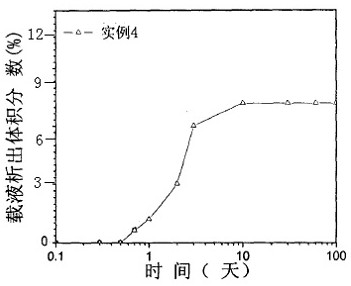

[0051] With 3.0g (0.5%) molybdenum disulfide (friction-reducing anti-wear agent), 3.0g (0.5%) organophosphorus compound (oxidant inhibitor), 6g (1%) organic bentonite (thixotropic agent), 27g ( 4.5%) ethylene glycol, 3.0g (0.5%) alkoxy thiophosphate (surfactant) were added to 81g (13.5%) low-viscosity silicone oil (PA0170), stirred, 504g Fe 3 0 4 The powder was added to the silicone oil, stirred at a high speed of 1000rpm to obtain a suspension, and the above suspension was compounded and reacted at a temperature of 70°C for 2 hours to prepare an oil-based magnetorheological fluid.

[0052] Put the magnetorheological fluid prepared in this example into a 10ml measuring cylinder, let it settle at room temperature, and observe its sedimentation rate after 3 months. Among them, the sedimentation rate is determined according to the following method: after standing for 3 months of sedimentation, take the ratio of the volume of the supernatant to the total volume of the sample, multi...

Embodiment 2

[0055] 4.2g (0.7%) antifriction and antiwear agent molybdenum disulfide and graphite (1:1), 6g (1%) thixotropic agent organic bentonite, 15g (2.5%) ethylene glycol, 4.8g (0.8%) surface Activator alkoxythiophosphate was added to 45g (7.5%) low-viscosity silicone oil (PA0168) and stirred, 537g of Fe, Co and Ni alloy particle powder was added to the silicone oil, stirred at a high speed of 1000rpm to obtain a suspension, and The above suspension was compounded and reacted at a temperature of 70°C for 2 hours to prepare an oil-based magnetorheological fluid.

[0056] Put the magnetorheological fluid prepared in this example into a 10ml measuring cylinder, let it settle at room temperature, and observe its sedimentation rate after 3 months. Among them, the sedimentation rate is determined according to the following method: after standing for 3 months of sedimentation, take the ratio of the volume of the supernatant to the total volume of the sample, multiply it by 100%, and obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com