High-energy-density lithium ion battery and preparation method thereof

A lithium-ion battery, high energy density technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problem of excluding transition metal oxides, etc., to improve rate performance, reduce contact resistance, and improve cycle. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment prepares high-energy-density lithium-ion batteries according to the following steps:

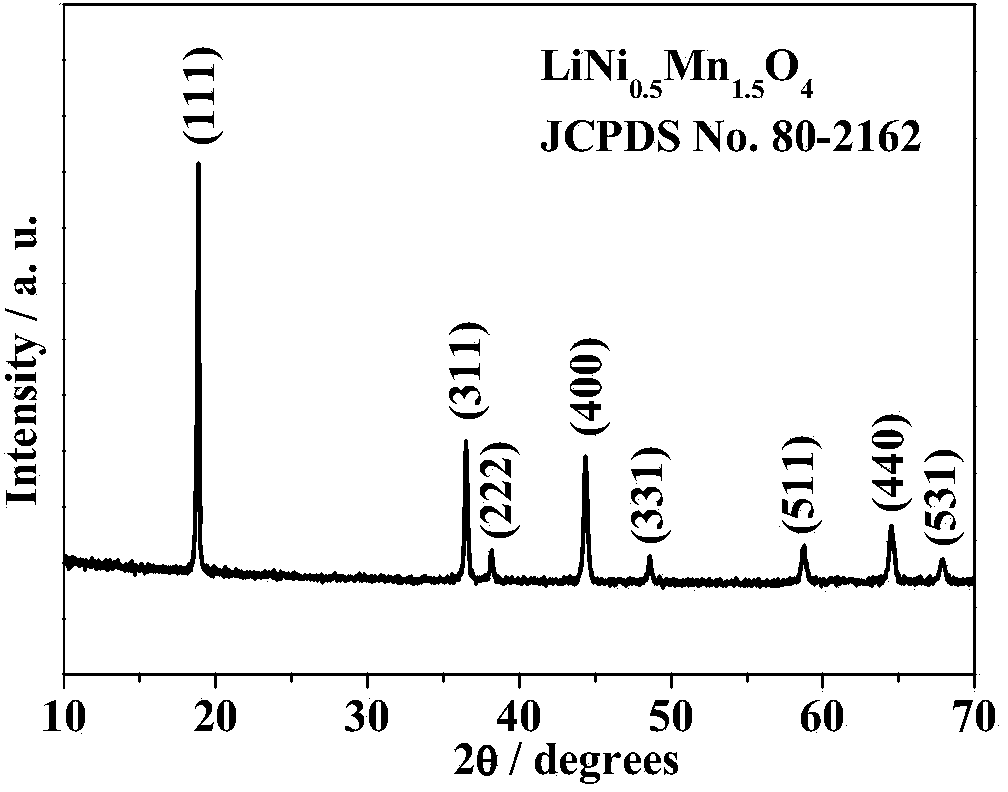

[0033] 1. Preparation of positive electrode sheet: lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 Positive electrode active material (its XRD figure is as shown in figure 1 shown), the conductive agent acetylene black, and the binder polyvinylidene fluoride (PVDF) are mixed according to the mass ratio of 80:10:10, and the mixture is prepared into a slurry with 1-methyl-2-pyrrolidone (NMP). coated on an aluminum foil current collector with a thickness of 20 μm, dried at 65° C., and sliced to obtain a positive electrode sheet.

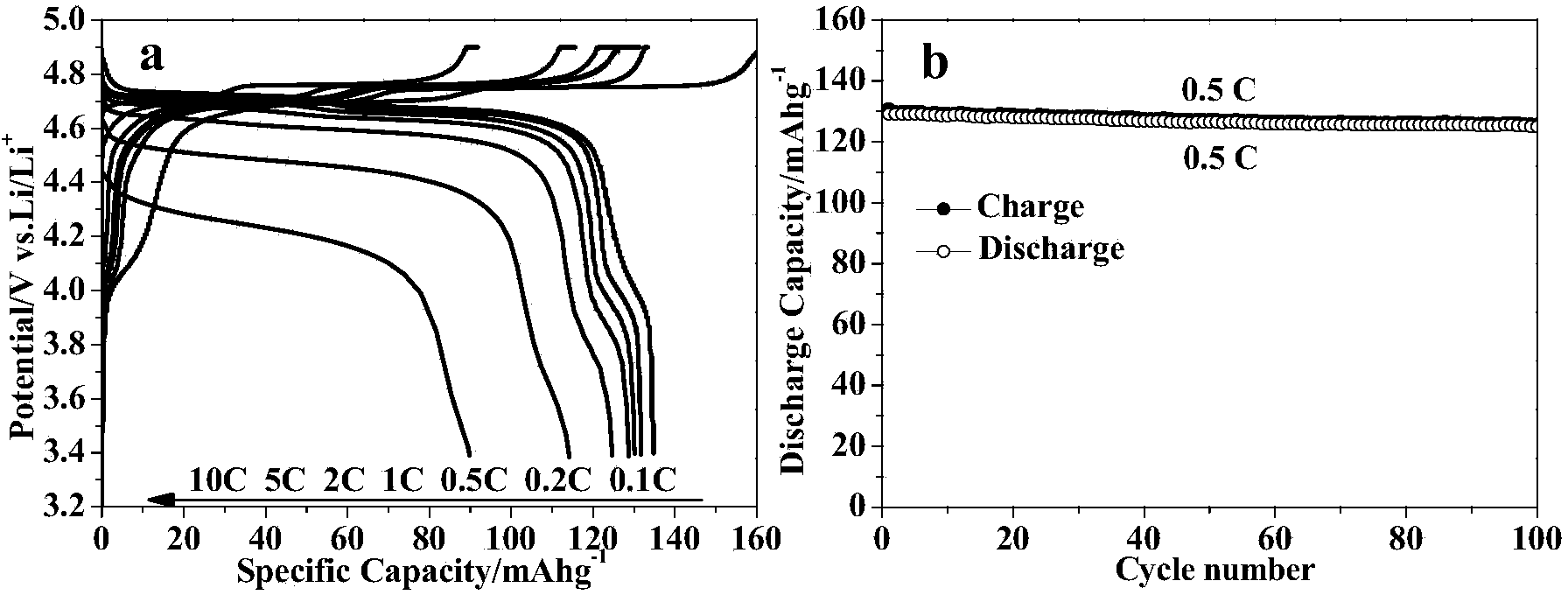

[0034] In order to test the performance of the obtained positive electrode sheet, the positive electrode sheet and the lithium sheet were assembled into a half-cell, and its electrochemical performance and cycle performance were tested at different rates. The results are as follows: figure 2 shown. Its charge-discharge curves at diffe...

Embodiment 2

[0041] This embodiment prepares high-energy-density lithium-ion batteries according to the following steps:

[0042] 1. Preparation of positive electrode sheet: LiNi 0.5 mn 1.5 o 4 The positive electrode active material, conductive agent acetylene black, and binder polyvinylidene fluoride (PVDF) are mixed according to the mass ratio of 80:10:10, and the mixture is prepared into a slurry with 1-methyl-2-pyrrolidone (NMP). coated on an aluminum foil current collector with a thickness of 20 μm, dried at 65° C., and sliced to obtain a positive electrode sheet.

[0043] 2. Preparation of the negative electrode sheet: Clean the base of the foamed nickel metal current collector, then put it into a 40mL aqueous solution containing 1mmol / L NiSO4 and 10mmolurea, react for 6h under hydrothermal conditions at 100°C, wash and dry, Calcined at 300°C for 6h in air to obtain NiO thin film.

[0044] 3. Battery assembly: Assemble the battery core in the order of positive electrode sheet-d...

Embodiment 3

[0047] This embodiment prepares high-energy-density lithium-ion batteries according to the following steps:

[0048] 1. Preparation of positive electrode sheet: 0.5Li 2 MnO 3 0.5LiMO 2 The positive electrode active material, conductive agent acetylene black, and binder polyvinylidene fluoride (PVDF) are mixed according to the mass ratio of 75:15:10, and the mixture is prepared into a slurry with 1-methyl-2-pyrrolidone (NMP). coated on an aluminum foil current collector with a thickness of 20 μm, dried at 65° C., and sliced to obtain a positive electrode sheet.

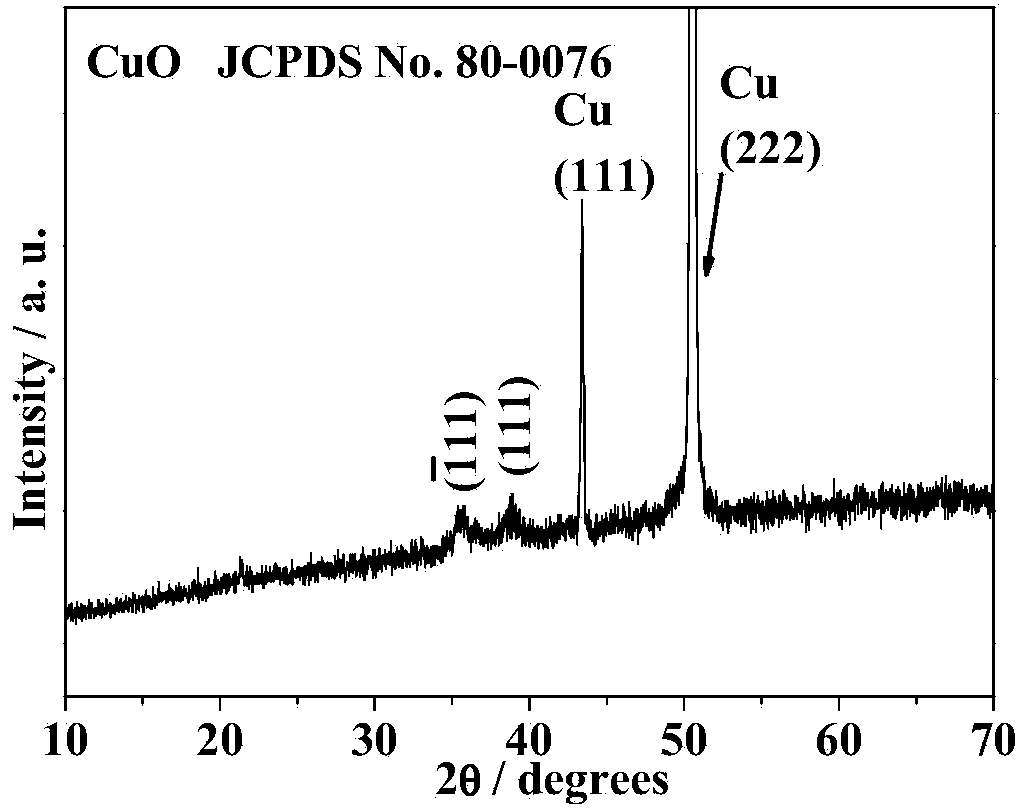

[0049] 2. Preparation of the negative electrode sheet: clean the base of the foamed nickel metal current collector, and then put 40mL of 0.1mol / L Cu(NO 3 ) 2 In the aqueous solution, add 3 mL of 0.5 mol / L NH 3 ·H 2 O aqueous solution was reacted in a water bath at 60° C. for 4 h, washed and dried to obtain a CuO nanosheet film.

[0050] 3. Battery assembly: Assemble the battery core in the order of positive el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com