Carbon potential operator

A calculus and carbon potential technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of high development cost, influence on popularization and application, high price, etc., achieve accurate and reliable characterization, and simplify calculation The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

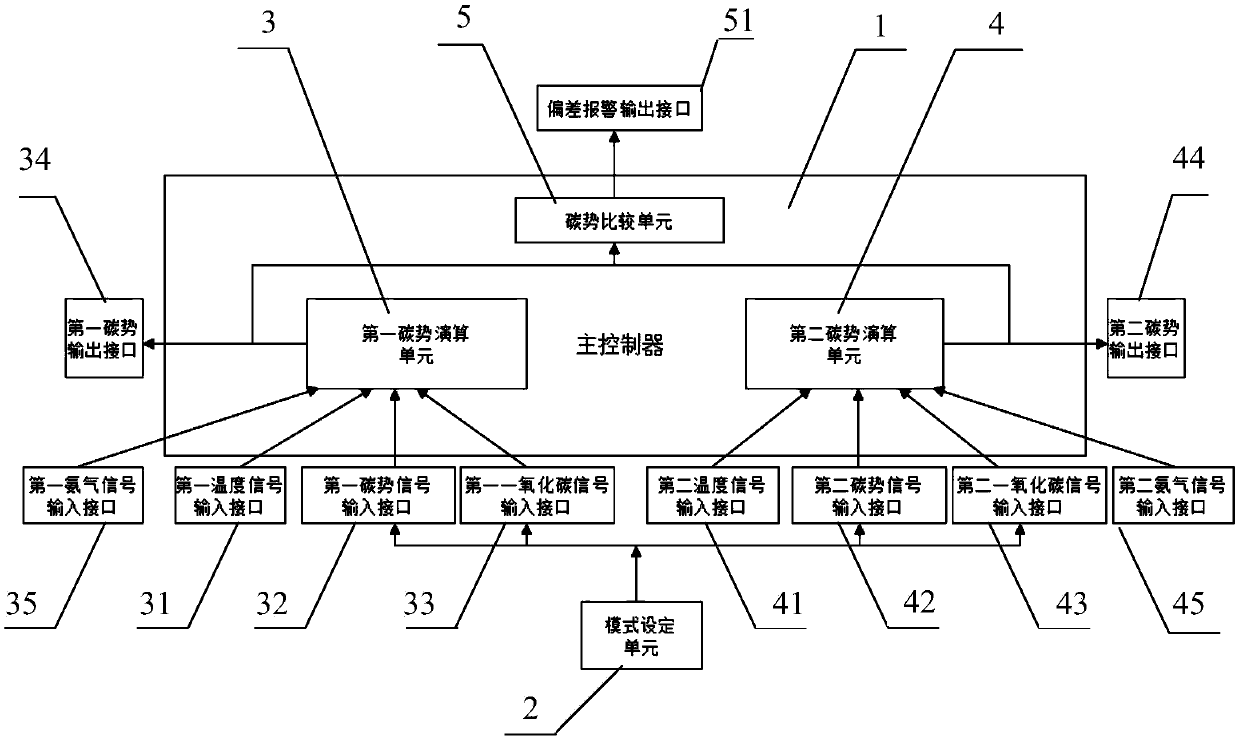

[0014] The carbon potential calculation device in the present embodiment includes a main controller 1 and a mode setting unit 2, the main controller adopts a programmable logic controller (PLC), and the main controller includes a first carbon potential calculation unit 3 And the second carbon potential calculation unit 4, two carbon potential calculation units are set to make the characterization of carbon potential more accurate and reliable.

[0015] The first carbon potential calculation unit 3 includes a first temperature signal input interface 31, a first carbon potential signal input interface 32, a first carbon monoxide signal input interface 33, and a first carbon potential output interface 34; the first temperature signal input interface The interface 31 is used to input the temperature of the atmosphere in the furnace; the first carbon potential signal input interface 32 is used to input the content of the first carbon potential gas in the atmosphere in the furnace, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com