A super-long shallow-buried construction method for existing pipelines in complex environments

A technology with complex environment and construction methods, applied in earthwork drilling, wellbore lining, tunnel lining, etc., to achieve the effect of firm and safe structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

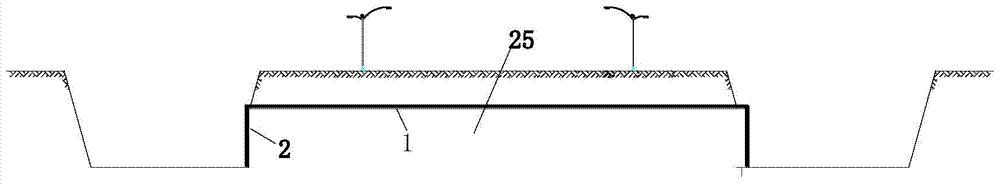

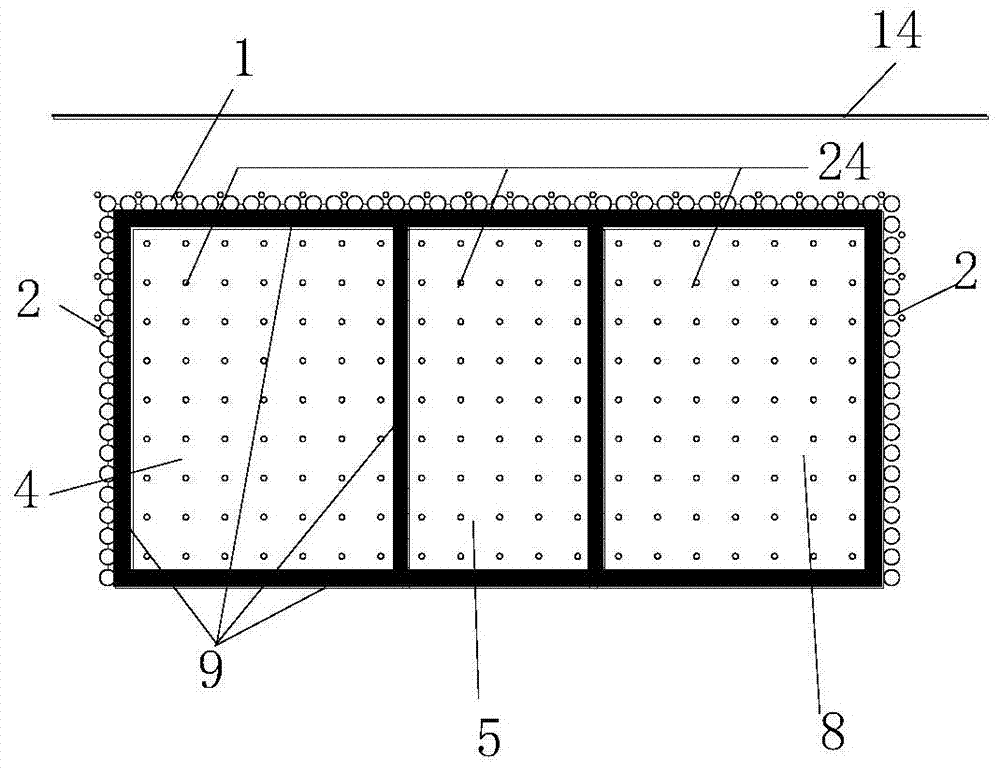

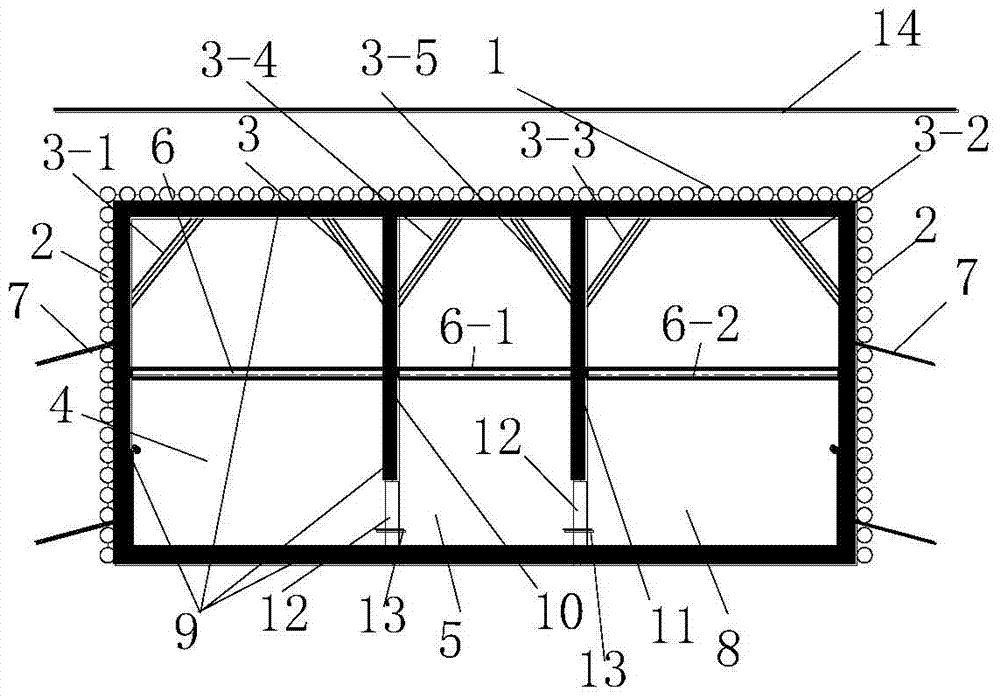

[0052] (1) The top elevation position of the underground passage 25 set below the pipeline of the road 14 and within the length of the underground passage 25 along the width direction of the road from one side of the road to the other side of the road, a plurality of tunnels are arranged in close proximity to each other The top pipe curtain 1 of each two adjacent top pipe curtains 1 is connected by an angle steel lock; then within the height range of the underground passage 25, at the position of the two side walls of the underground passage 25, along the road width direction from the side of the road To the other side of the road, a plurality of side tube curtains 2 closely arranged up and down are arranged in turn, and every two adjacent side tube curtains 2 are connected by angle steel locks; the top tube curtain 1 and the two sides The outer pipe curtain 2 is composed of multiple sections of steel pipes. When the jacking of one section of steel pipes is completed and the ne...

Embodiment 2

[0070] (1) The top elevation position of the underground passage 25 set below the pipeline of the road 14 and within the length of the underground passage 25 along the width direction of the road from one side of the road to the other side of the road, a plurality of tunnels are arranged in close proximity to each other The top pipe curtain 1 of each two adjacent top pipe curtains 1 is connected by an angle steel lock; then within the height range of the underground passage 25, at the position of the two side walls of the underground passage 25, along the road width direction from the side of the road To the other side of the road, a plurality of side tube curtains 2 closely arranged up and down are arranged in turn, and every two adjacent side tube curtains 2 are connected by angle steel locks; the top tube curtain 1 and the two sides The outer pipe curtain 2 is composed of multiple sections of steel pipes. When the jacking of one section of steel pipes is completed and the ne...

Embodiment 3

[0088] (1) The top elevation position of the underground passage 25 set below the pipeline of the road 14 and within the length of the underground passage 25 along the width direction of the road from one side of the road to the other side of the road, a plurality of tunnels are arranged in close proximity to each other The top pipe curtain 1 of each two adjacent top pipe curtains 1 is connected by an angle steel lock; then within the height range of the underground passage 25, at the position of the two side walls of the underground passage 25, along the road width direction from the side of the road To the other side of the road, a plurality of side tube curtains 2 closely arranged up and down are arranged in turn, and every two adjacent side tube curtains 2 are connected by angle steel locks; the top tube curtain 1 and the two sides The outer pipe curtain 2 is composed of multiple sections of steel pipes. When the jacking of one section of steel pipes is completed and the next...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com