Anti-icing structure of PCV opening of escape pipe of air cleaner of air inlet system

A technology of air intake system and air outlet pipe, applied in the direction of fuel air filter, fuel air intake port, etc., can solve the problems of damaged crankcase seal, high pressure, poor lubrication performance, etc., and achieve the goal of avoiding freezing blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

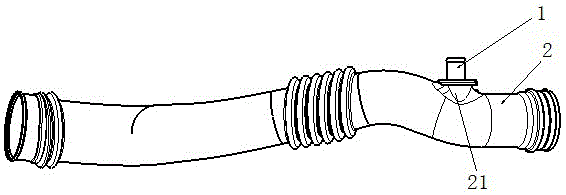

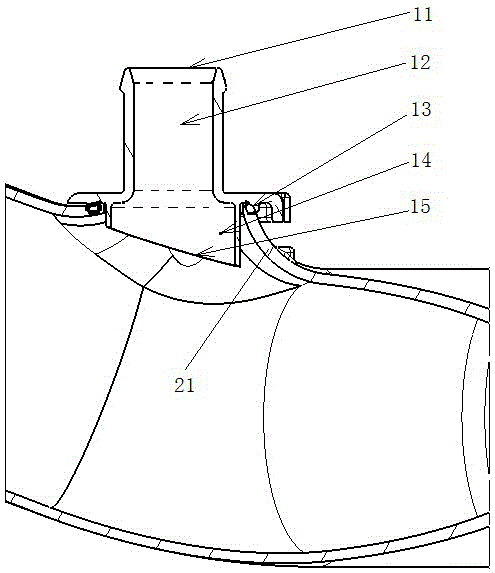

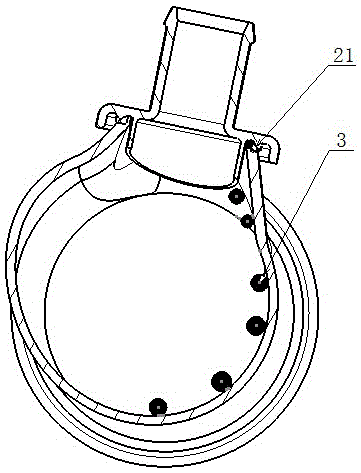

[0015] Such as figure 1 , 2 As shown, an air intake system air filter outlet pipe PCV port anti-icing structure, including a PCV joint 1 and an air filter outlet pipe 2, the air filter outlet pipe 2 is provided with a PCV port, and one end of the PCV joint 1 is fixed Installed on the PCV port, the other end of the PCV joint 1 communicates with the crankcase ventilation pipe, and the PCV port naturally extends outward to the PCV port connection section 21, and the PCV joint 1 includes a ventilation pipe section 12, a joint surface 13 and an air outlet pipe section 14. The inner wall of the connection between the ventilation pipe section 12 and the air outlet pipe section 14 is smoothly transitioned, the joint surface 13 is set at the junction of the ventilation pipe section 12 and the air outlet pipe section 14, and the air outlet pipe section 14 is inserted into the connection section of the PCV port In 21, the PCV joint 1 is sealed and fixedly installed on the PCV port conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com