Water-absorbing tube cleaner

A technology of pipe cleaners and water collectors, which is applied in the field of petroleum engineering, and can solve problems such as poor sealing and wear of pipe cleaner cups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The purpose of the present invention is to develop a water suction pig for cleaning the residual water in the low-lying part of the natural gas and oil pipeline, thereby effectively slowing down the corrosion and ice blockage of the pipeline.

[0025] The technical solutions in the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation manners.

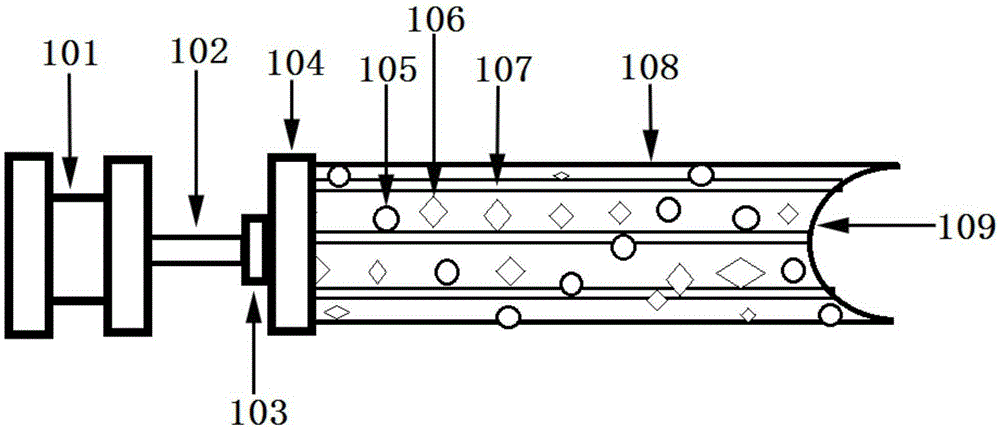

[0026] Such as figure 1 As shown, the present embodiment provides a water suction pig, comprising:

[0027] Cylindrical metal cylinder 108, the cylinder wall of cylindrical metal cylinder 108 is a hollowed-out mesh structure, and the mesh diameter of the mesh structure is between 0.1 mm and 5 cm;

[0028] The polymer water-absorbing resin 106 is located in the cylindrical metal cylinder 108, and the polymer water-absorbing resin 106 has a strong water-absorbing capacity;

[0029] The arc-shaped water collector 109 is arranged on the front end of the cylind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com