Gas direct contact type ice slurry preparation device with precooling sleeve

A contact type, ice slurry technology, applied in ice making, ice making, lighting and heating equipment, etc., can solve the problems of ice hockey condensation, complex heat transfer, etc., to achieve easy construction and maintenance, uniform temperature distribution, and heat exchange area Increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

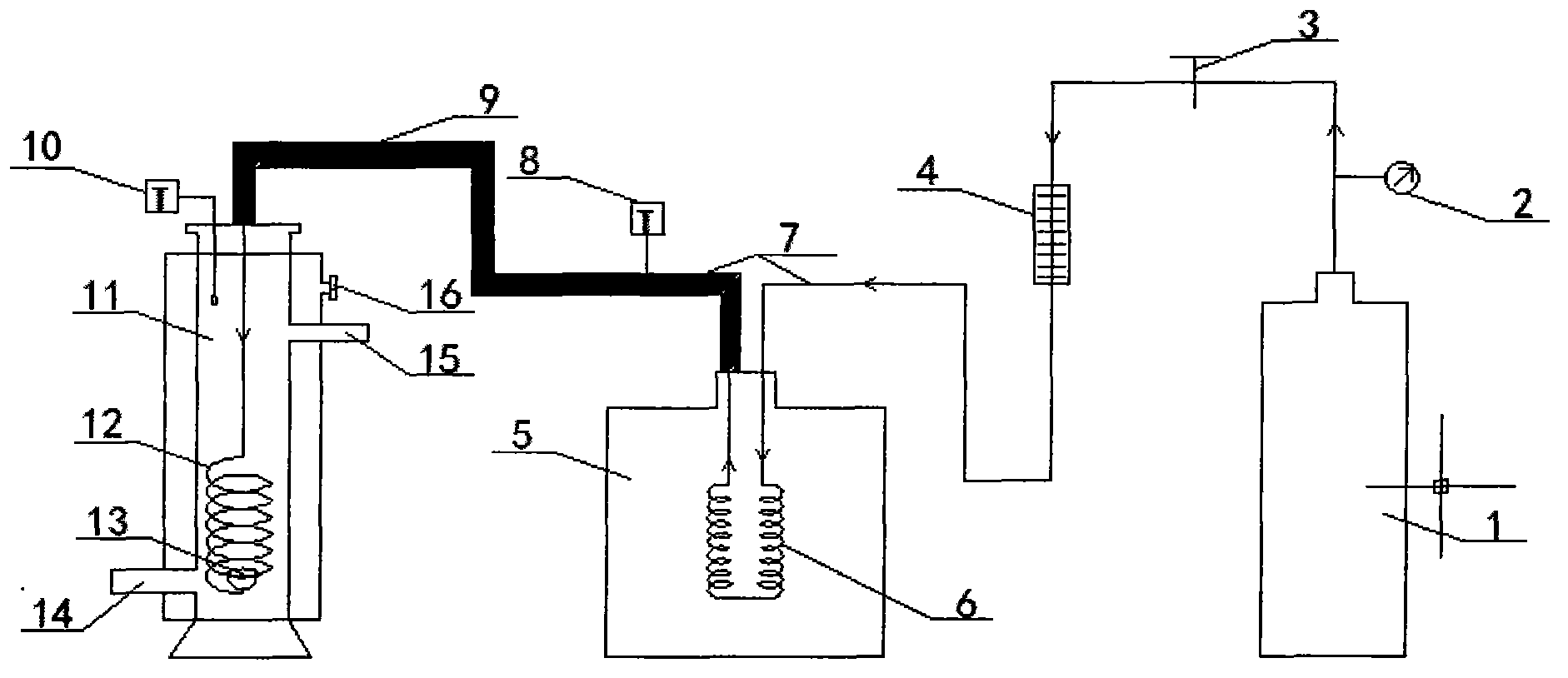

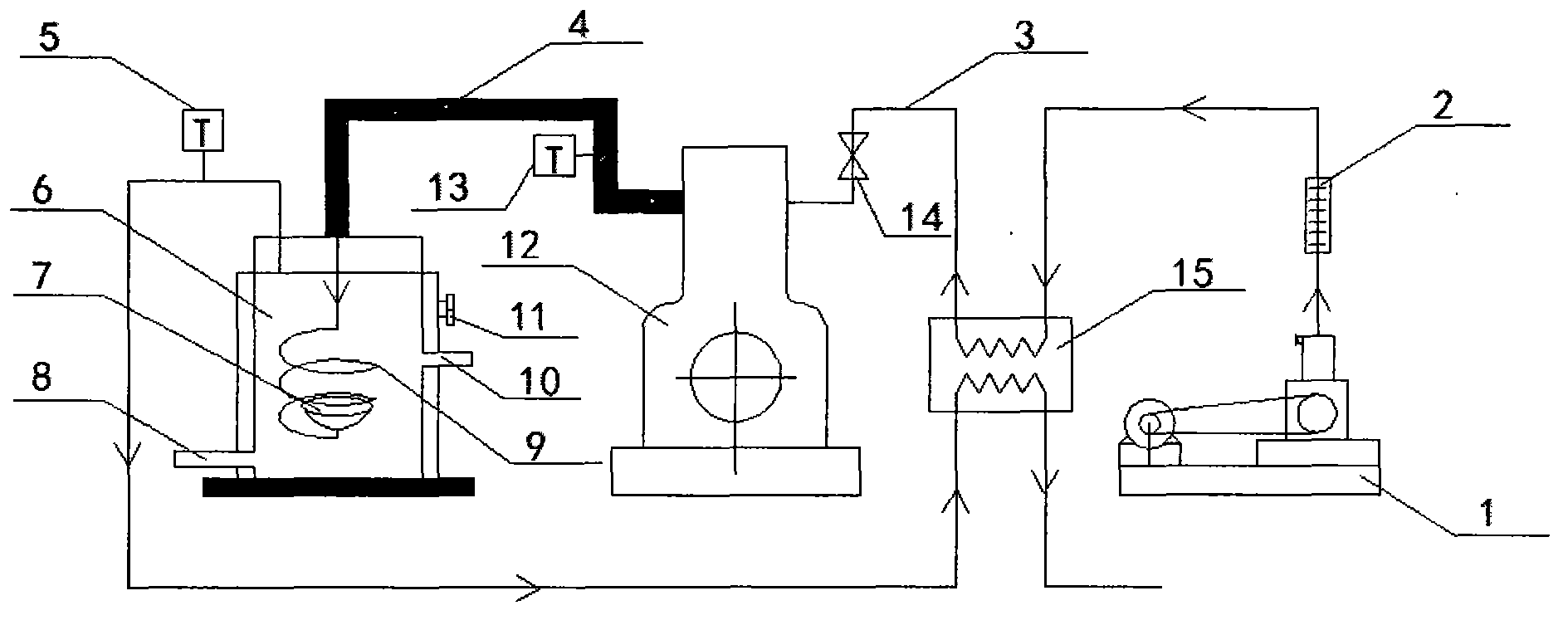

[0051] Take the production and living device as an example (the experimental device is the same): the brine gas passes through the gas supply device 1 (such as an air compressor), and the flow measurement control device 2 (such as a rotameter) controls the flow of the brine gas during the experiment. The flow rate is controlled and recorded, and the flow rate of the refrigerant gas is adjusted to obtain the fastest ice slurry production speed. The refrigerant gas passes through the flow meter 2 and then enters the regenerator 15 through the stainless steel tube 3. The cold gas is fully heat-exchanged for a certain cooling, and then enters the throttle valve 14 for a certain throttling and cooling, and finally in the cooling device. 12 (such as a refrigeration system) to be cooled to the required temperature, and the temperature is measured by a temperature sensor 13 (such as a thermocouple). The cooled brine gas still enters the stainless steel pipe 3, but all the pipes behind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com