Screw pump

A screw pump and stator technology, used in pumps, pump control, rotary piston pumps, etc., can solve problems such as preload mismatch, reduced service life, and low life of screw pump rotors and stators. The effect of improving the service life and improving the balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

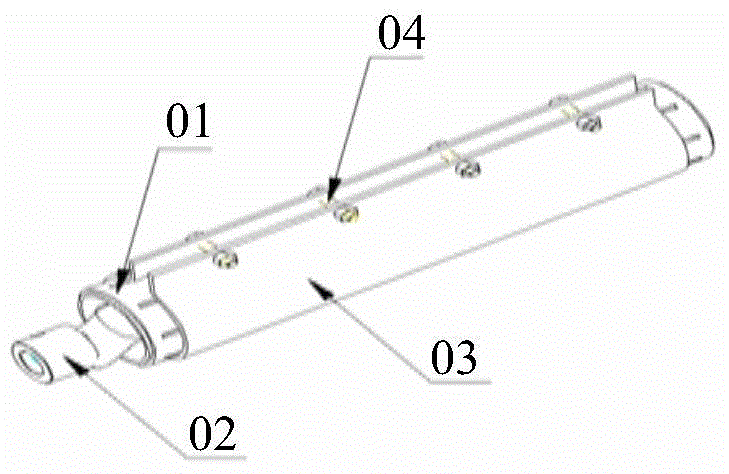

Image

Examples

Embodiment approach

[0048] Mode 1, each clamping hoop can be a hoop.

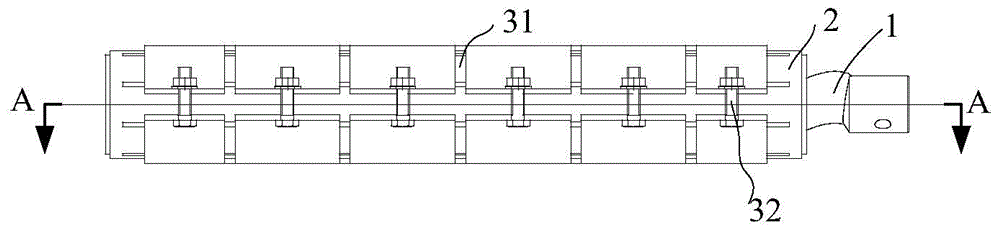

[0049] On the basis of the above method 1, if Figure 6 and Figure 7As shown, each hoop is hinged on the same shaft 6 , and the axis line of the shaft 6 is parallel to the axis line of the stator 2 .

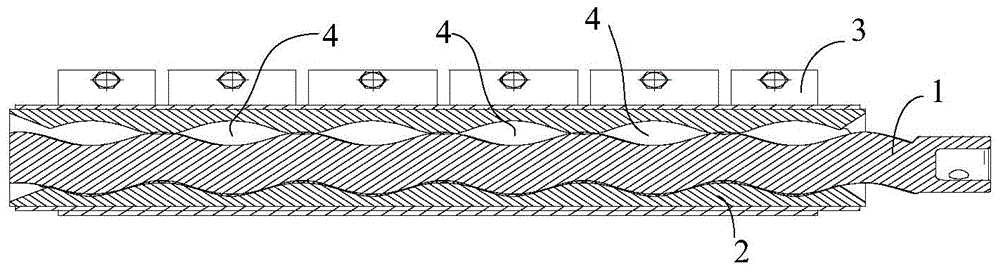

[0050] Such as Figure 6 and Figure 7 As shown, a plurality of hoops are arranged in the axial direction of the screw pair, and each hoop is jointly hinged on the same shaft 6, and each hoop hinged on the shaft 6 is wrapped tightly and neatly on the outside of the stator 2, but each hoop Each hoop can adjust the force of the hoop on the corresponding stator 2 by adjusting the bolts on it, so as to realize the adjustment of the pre-tightening force between the part of the stator 2 and the hoop corresponding to the rotor 1 .

[0051] Such as Figure 8 ~ Figure 9 As shown, each clamp can be a double-bolt clamp 5, and the double-bolt clamp 5 is composed of two half-closed clamps.

[0052] Please refer to figure 2 , combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com