Multi-joint synchronous rotary axle structure

A rotating shaft structure and side shaft technology, applied in the field of multi-section rotating shaft structure, can solve the problems of large number of components, difficult to control the tightness, easy leakage of lubricating grease, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

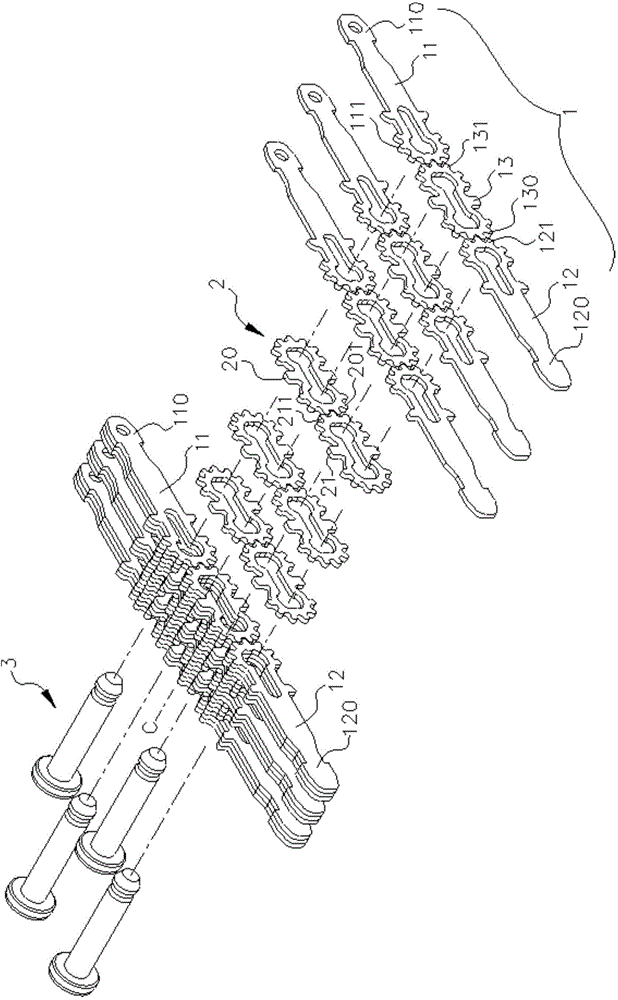

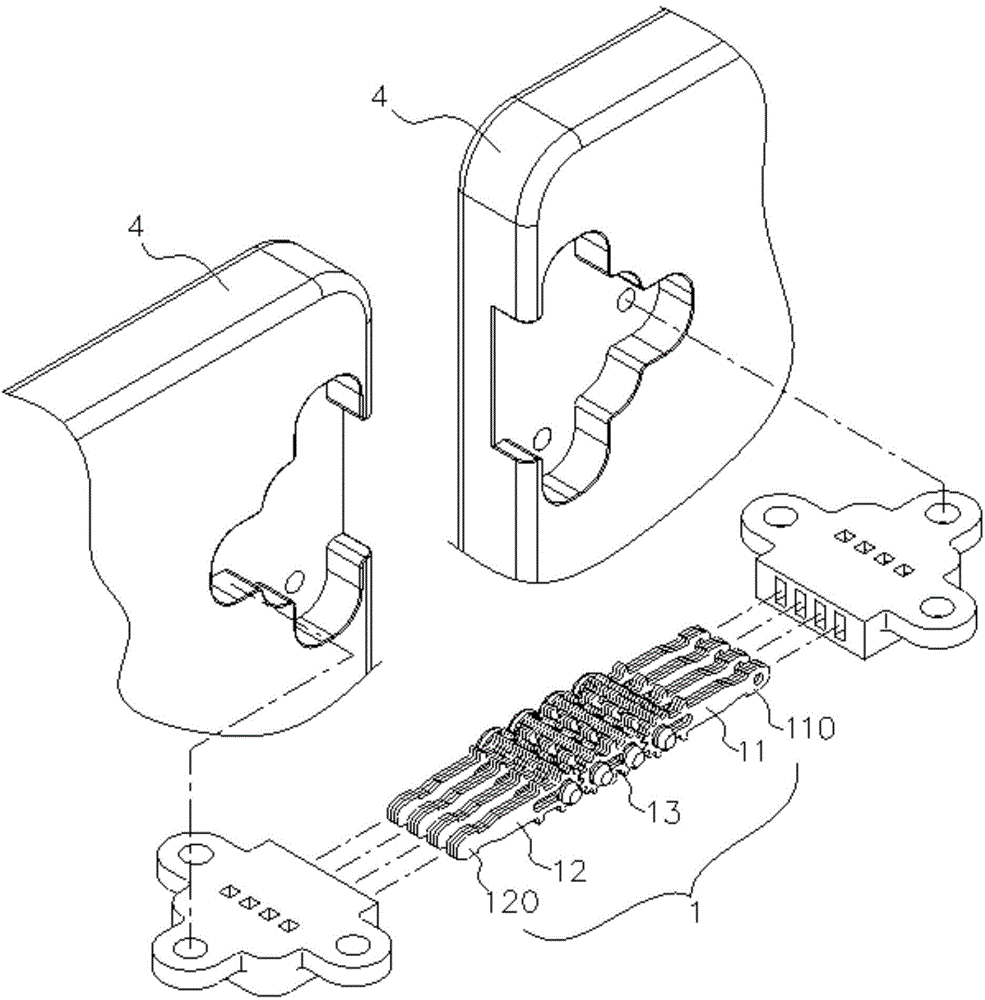

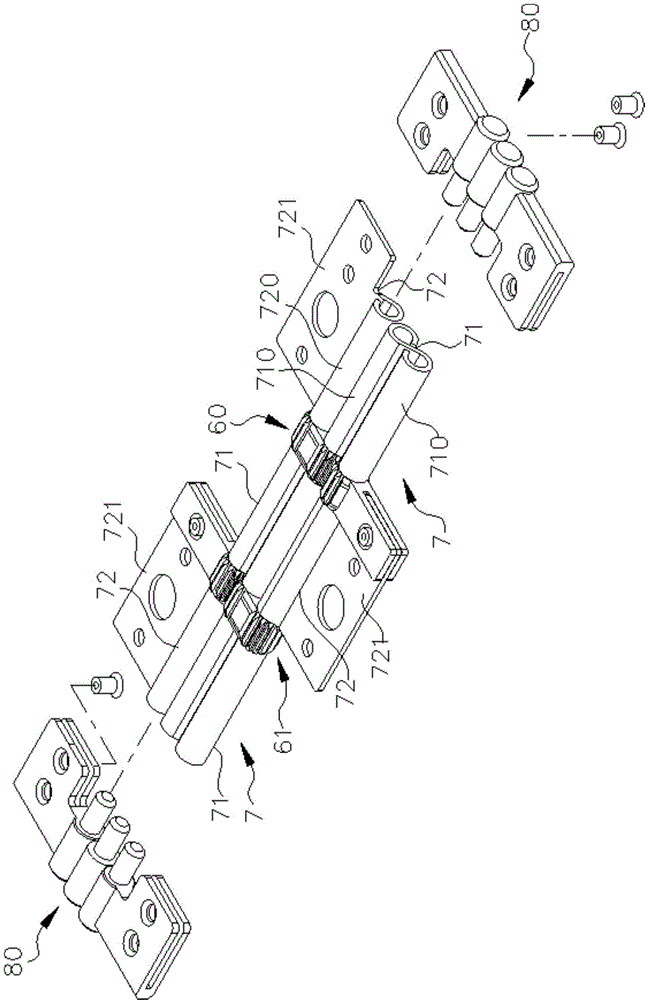

[0060] Please refer to Figure 3 to Figure 5 , the present invention includes a central axis 40 and two side shafts arranged in parallel on both sides of the central axis 40, which include a first side shaft 50 and a second side shaft 51, corresponding to the central shaft 40 and the two side shafts 50, 51 At a first position 400, 500, 510 and a second position 401, 501, 511 of the center shaft 40 and the two side shafts 50, 51, respectively, a first synchronous drive group 60 and a second synchronous Two synchronous actuation groups such as the actuation group 61, the two synchronous actuation groups 60, 61 are combined in opposite directions with respect to the joint between the central shaft 40, the first side shaft 50 and the second side shaft 51; as shown in the accompanying drawings , the first synchronous actuator group 60 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com