Silent chain and silent chain transmission device

一种传动装置、无声链的技术,应用在传动链、链元件、皮带/链条/齿轮等方向,能够解决无声链与链轮啮合声变差、无声链弦振动声变大、链轮卷绕变差等问题,达到抑制爬齿、降低弦振动声、举动稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

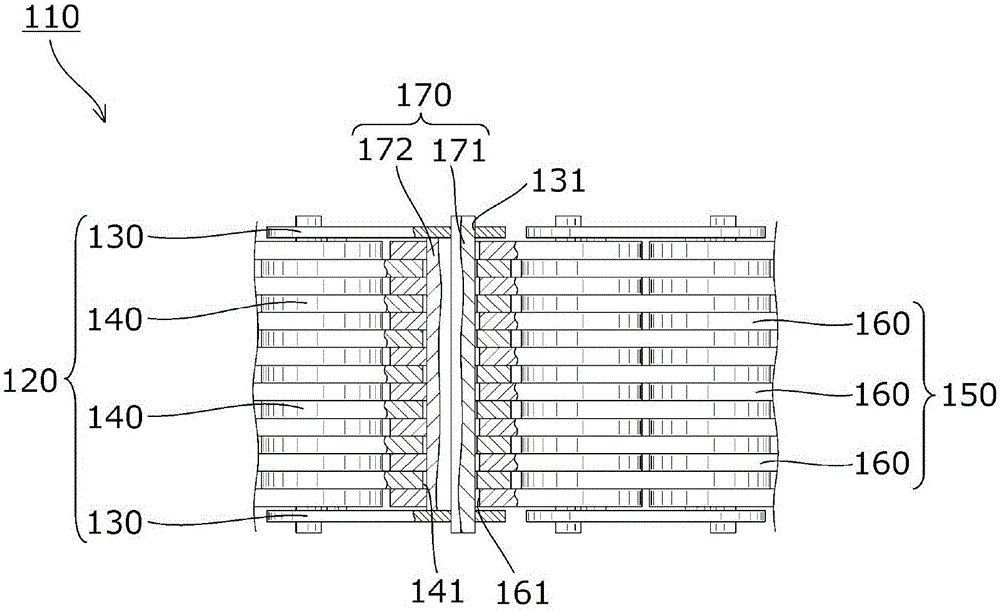

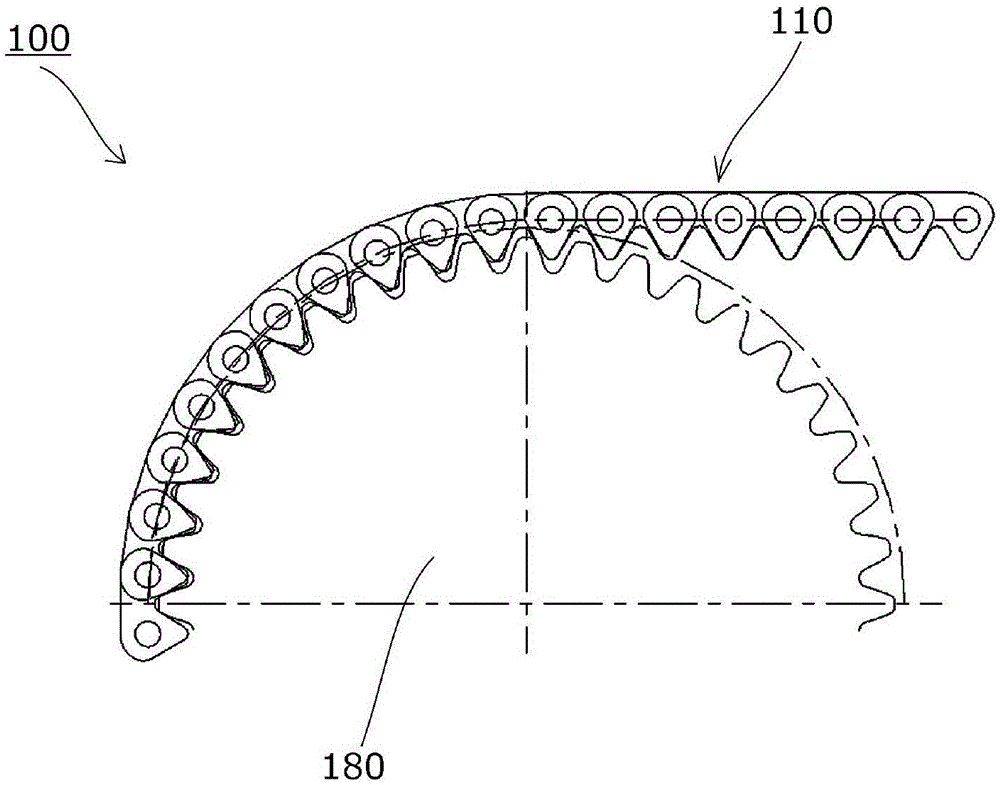

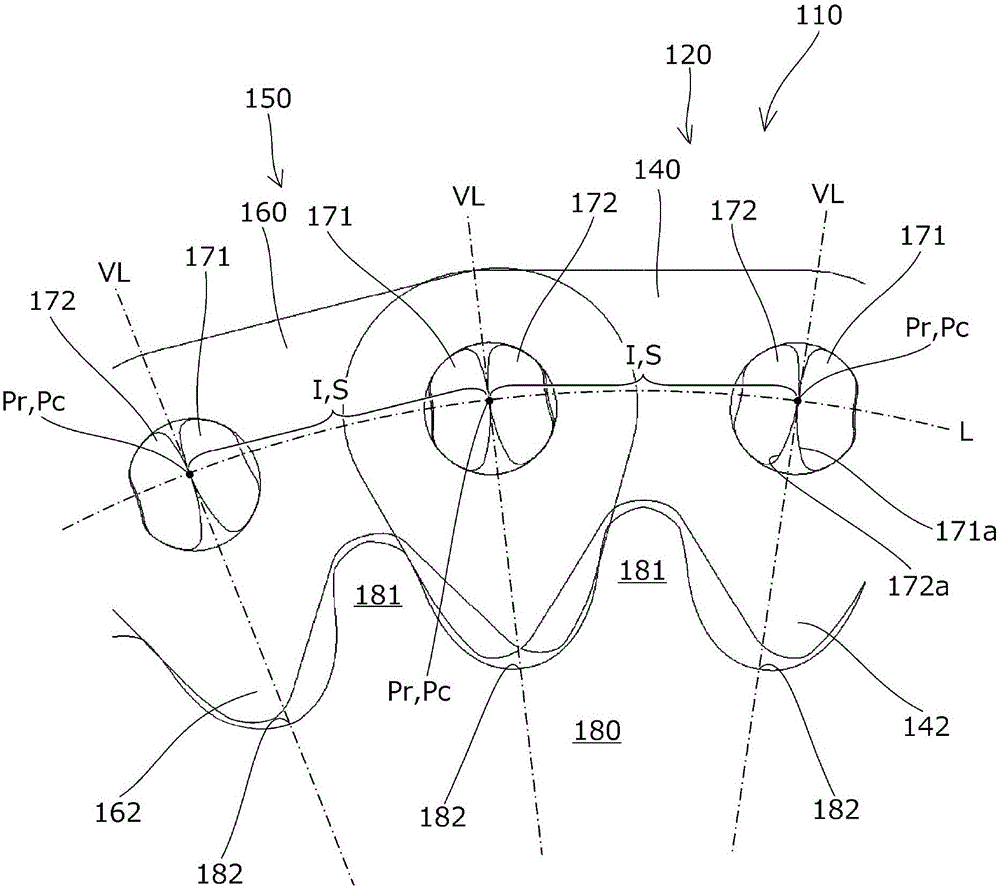

[0051] The silent chain 110 according to the first embodiment of the present invention is as follows: figure 1 As shown, a plurality of guide rows 120 and a plurality of non-guide rows 150 are arranged alternately with half a pitch staggered in the chain length direction, and are flexibly connected by a pair of rotating pins 170, as in figure 2 The silent chain 110 is wound around the sprocket 180 as shown in a part thereof, and the silent chain transmission device 100 according to the first embodiment of the present invention is constituted.

[0052] The guide row 120 of the silent chain 110 is composed of a pair of left and right guide plates 130 disposed on both outer sides in the chain width direction and a plurality of intermediate plates 140 disposed between the pair of left and right guide plates 130 . In addition, the non-guide row 150 is constituted by a plurality of inner flat plates 160 arranged side by side in the chain width direction.

[0053] A pair of rotati...

Embodiment 2

[0077] The silent chain according to the second embodiment of the present invention is as follows: Image 6 As shown, the diameters of the pin holes 241, 261 in the chain length direction of the middle plate and the inner plate are set to be larger than the diameters in the chain height direction, and the cross-sectional shapes of the long pins 271 and short pins 272 are also in the chain length direction. thick.

[0078] And, like the first embodiment, in the state where the pair of rotating pins 271, 272 contact each other through the rotating surfaces 271a, 272a, the pin hole 261 of the inner plate 260 has the seating surface 263 of the inner plate 260 and the short pin 272. The pin hole 241 of the middle plate 240 has a size that can form a gap between the seat surface 243 of the middle plate 240 and the back side of the long pin 271 .

[0079] That is, if Image 6 As shown, in the state where the back of the short pin 272 is located on the seat surface 263 of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com