Self-centering depth hole parameter measurement device

A technology of parameter measurement and centering device, which is applied to measurement devices, optical devices, instruments, etc., can solve problems such as low efficiency and small measurement range, and achieve the effect of ensuring accurate measurement and measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

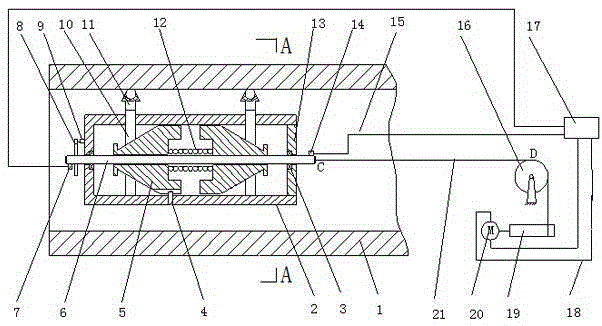

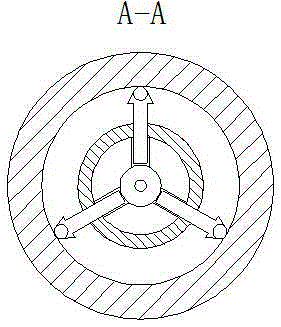

[0027] like figure 1 , 2 As shown, a self-centering deep hole parameter measurement device includes a centering device, a measurement recording device and a traveling device. The centering device is located in the deep hole of the workpiece 1, and the centering device includes a sleeve 2, a centering shaft 6, two cones 5, two bearings 3, six measuring rods and a spring 12, and the centering shaft 6 is located on the axis of the sleeve 2, and the centering shaft 6 is connected to the sleeve 2 through two bearings 3, two sets of through holes are opened on the wall of the sleeve 2, each set of through holes is three, and three The through holes are evenly distributed on the cross section perpendicular to the axis of the sleeve 2; the two cones 5 and the spring 12 are located in the sleeve 2, and are movable sleeved on the centering shaft 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com