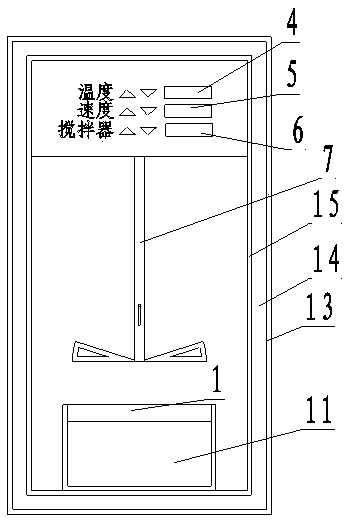

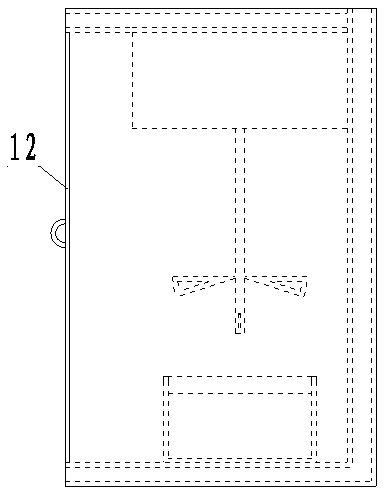

Small normal temperature modified asphalt processing device for indoor tests and use method thereof

A technology for indoor testing of modified asphalt at room temperature, applied in the preparation of test samples, etc., can solve the problems that the processing temperature and stirring speed of modified asphalt at room temperature cannot be simulated, and achieve the effect of easy moving, convenient maintenance, and light equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0042] As a specific example, if it is desired to process normal temperature modified asphalt at minus 10°C, the dosage of the modifier is 15%, the quality of the base asphalt is 2.0kg, and the stirring speed is 200r / min.

[0043] (1) Calculate the amount of modifier and the amount of asphalt put in each batch.

[0044] The total amount of modifier = mass of base asphalt × modifier dosage = 2.0kg × 15% = 0.3kg

[0045] The mass of each batch of base asphalt = the total amount of modifier / 2=0.3kg / 2=0.15kg

[0046] Batch quantity = mass of base asphalt / mass of each batch of base asphalt = 2.0kg / 0.15kg≈14 times

[0047] (2) Turn on the temperature control system of the environmental box, make the temperature of the environmental box reach the predetermined temperature: -10°C, and keep the temperature constant for more than 30 minutes.

[0048] (3) Put 0.3kg modifier into the processing barrel at one time;

[0049] (4) Put 0.15kg of the first batch of asphalt into a processing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com