Cylindrical test specimen lateral dynamic uniform distribution load testing apparatus

A test device and uniform loading technology, which is used in measurement devices, instruments, scientific instruments, etc., can solve the problems of inability to apply loads to structural specimens, harsh test conditions, and high danger, and achieve flexible and diverse loading methods and save testing. The effect of space and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

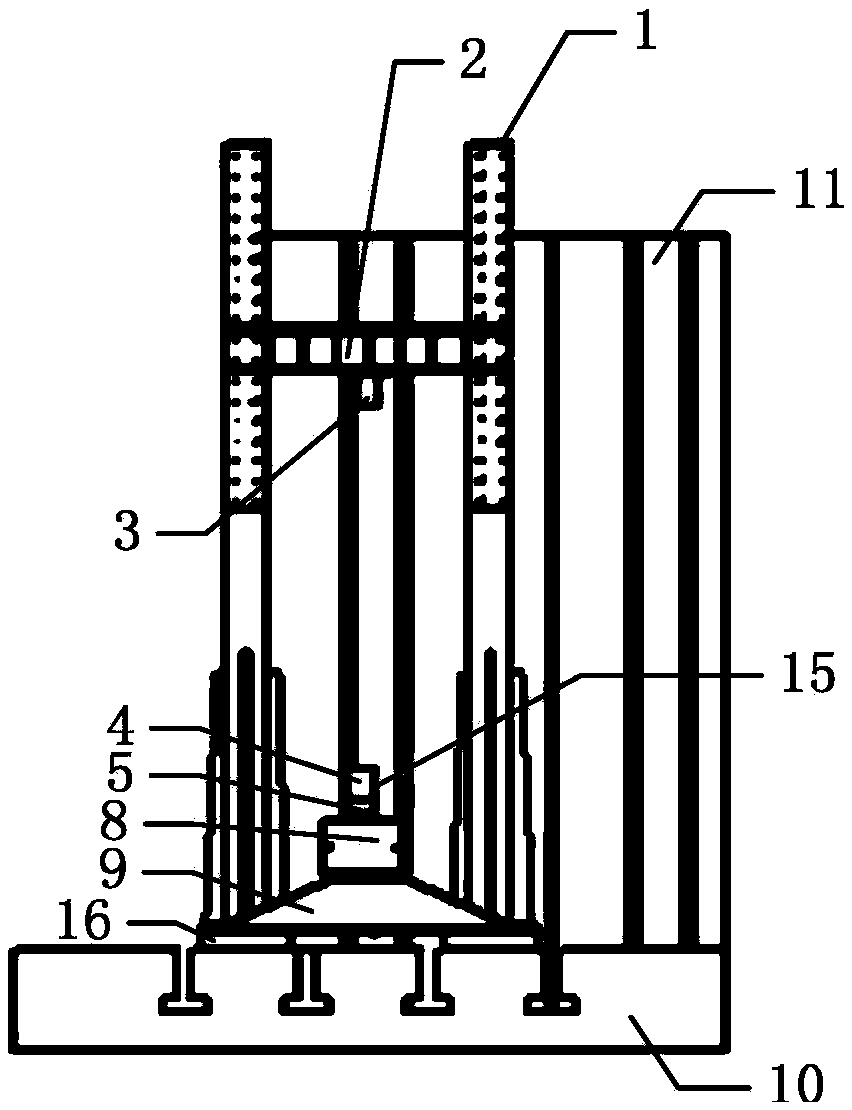

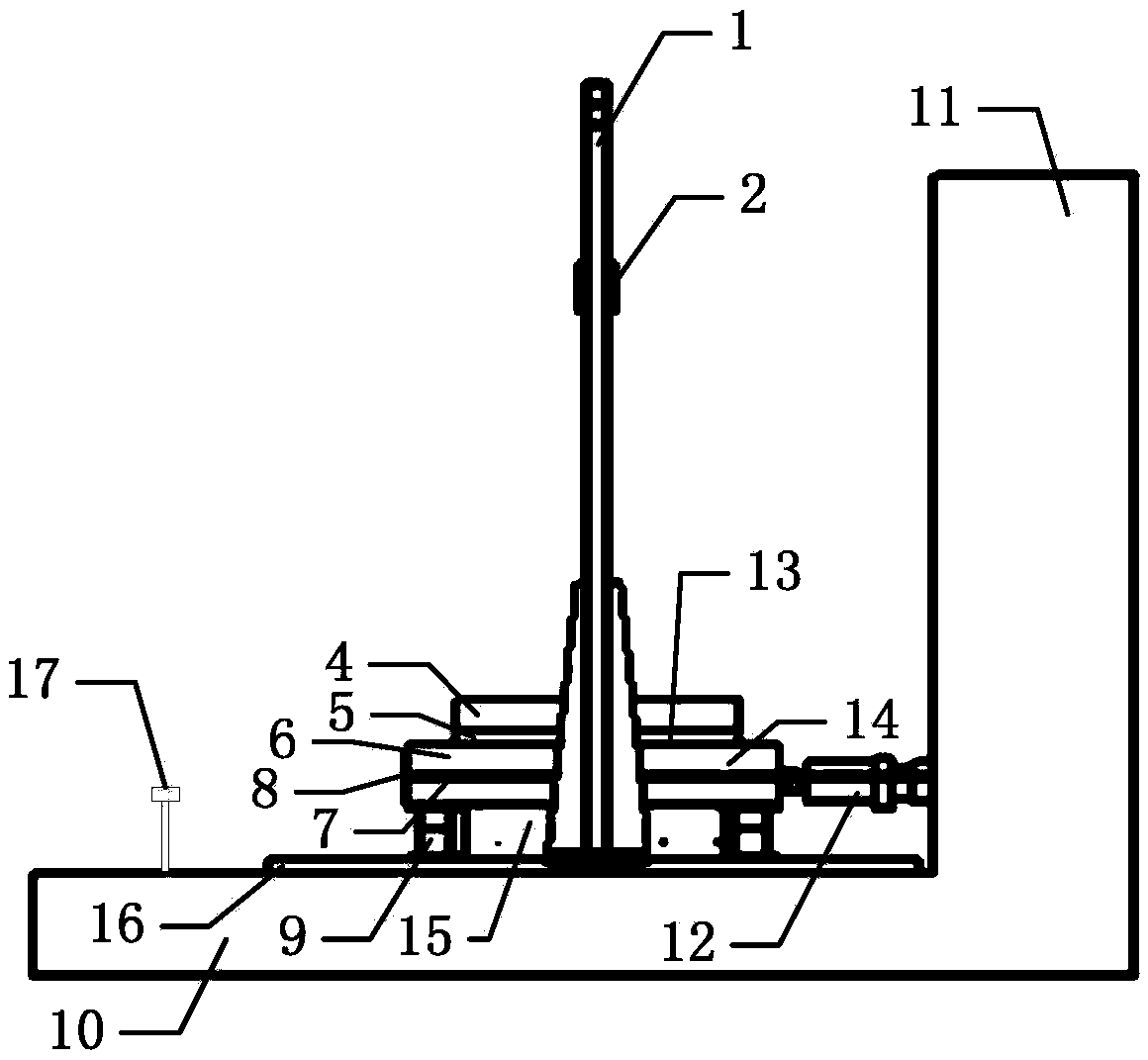

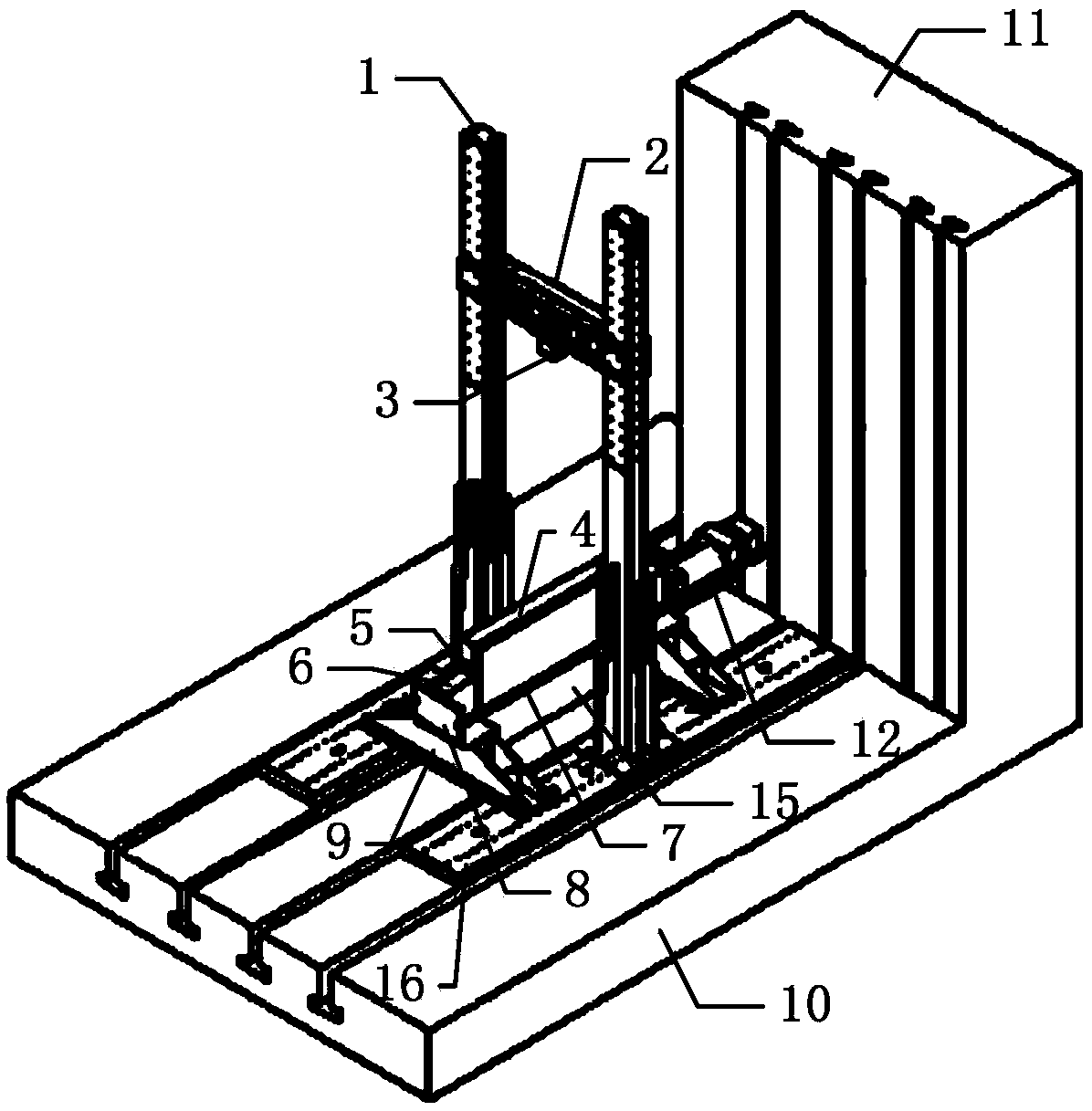

[0015] Such as Figure 1-3 As shown, the horizontal dynamic uniform loading test device of the columnar test piece of the present invention includes a reaction wall 11 located at one end of the columnar test piece 1, two supports 9 placed below the test piece 1 and close to the two ends of the test piece 1, The steel baffle 8 close to the other end of the test piece 1 also includes an anchor rod 7 and a horizontal actuator 12, one end of the anchor rod 7 is vertically connected to the steel baffle 8, and the other end is fixed on the reaction force In the vertical channel of the wall 11, the horizontal actuator 12 is placed between the reaction wall 11 and the test piece 1, one end of which is fixed on the reaction wall 11, and the other end withstands the test piece 6 and is close to the reaction force. one end of wall 11,

[0016] It also includes a door-type guide rail 1 perpendicular to the plane of the foundation 10, and a load-bearing beam 2 that can slide freely along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com