Portable 35KV fuse core replacing device and quick core replacing method

A fuse, portable technology, applied in the field of portable 35KV fuse core change device and quick core change, it can solve the problems of long time-consuming fuse change core, cumbersome operation, etc., to achieve simple and clear steps, simple operation and reliability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

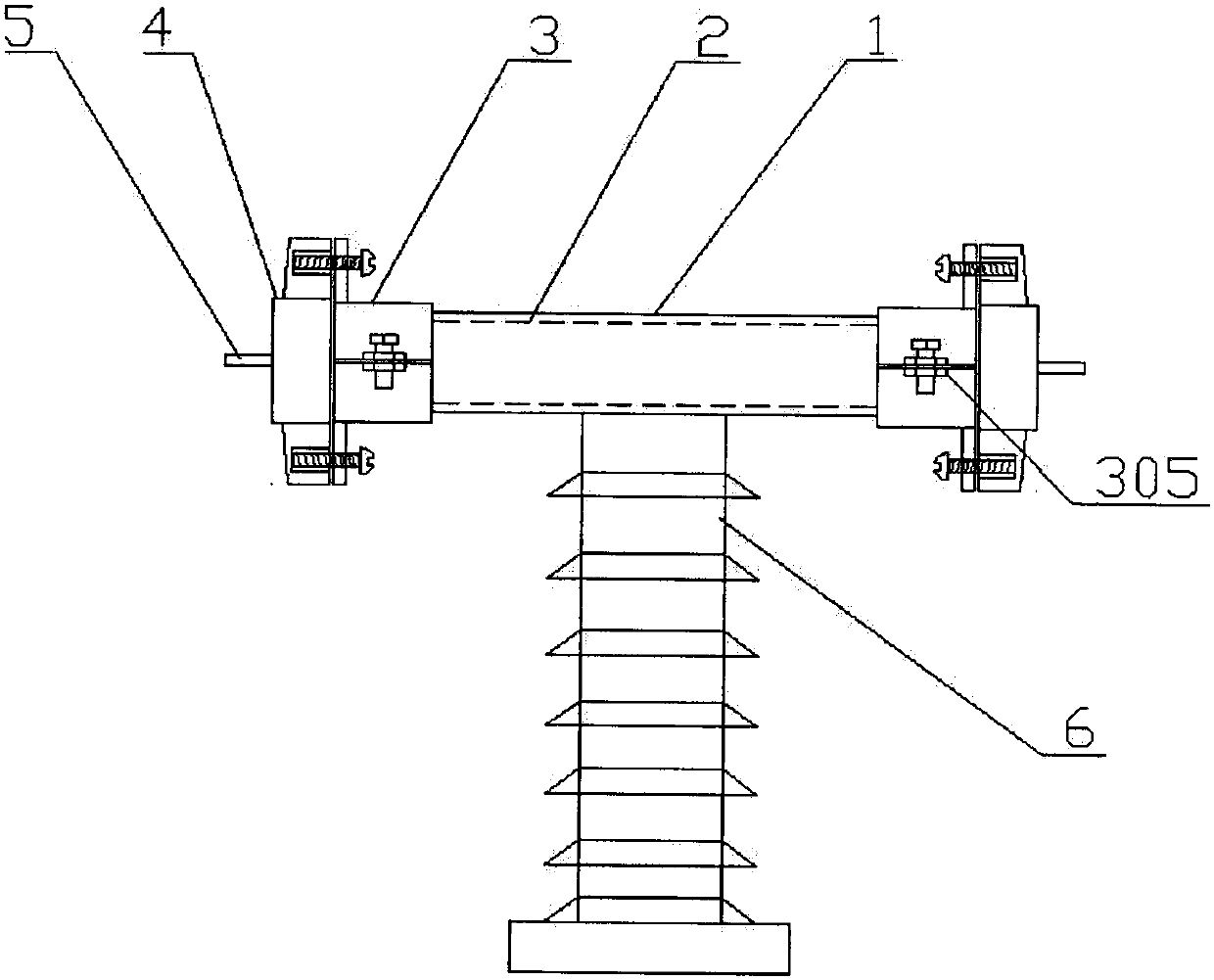

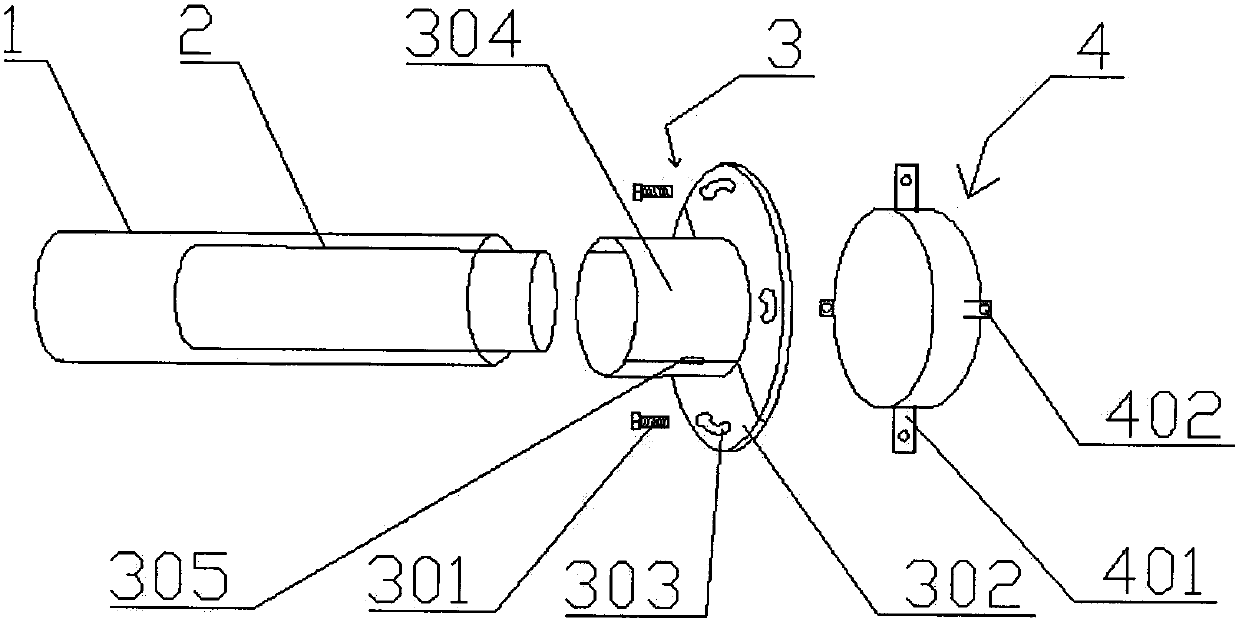

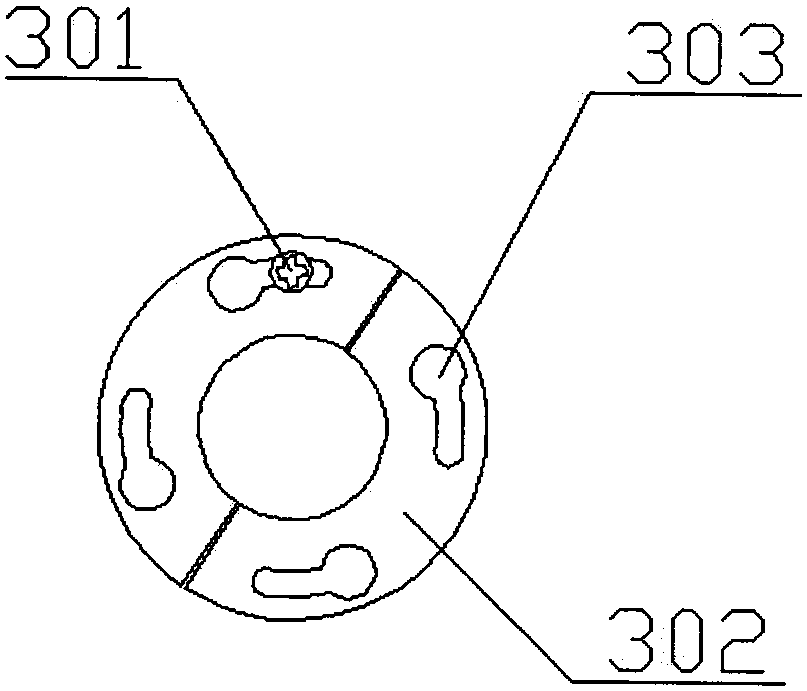

[0037] Embodiment 1: see figure 1 , figure 2 , a convenient 35KV fuse core replacement device, including a fuse sleeve 1, a fuse tube 2, a cover clamp 3, a terminal cover 4, and a terminal 5; the fuse sleeve 1 is fixed on a supporting insulator 6 Above, the terminal cover plate 4 is set at both ends of the fuse sleeve 1, and forms a closed area with it to enclose the fuse tube 2; the fuse tube 2 forms a circuit connection with the terminal 5; the fuse sleeve 1 and the terminal The cover plate 4 is connected through the cover plate clamper 3; the left end of the cover plate clamper 3 is fixedly connected with the fuse porcelain sleeve 1; Detachable connection, the terminal cover is provided with an engaging part corresponding to the track slot, the engaging part is located in the narrow area of the track slot 303, the terminal cover is clamped, and the engaging part is located in the track slot 303 In the open area the terminal cover is loosened.

[0038] see figure 2 ,...

Embodiment 2

[0039] Example 2: see Figures 1 to 5 , the portable 35KV fuse core changing device of this embodiment is basically the same as that of Embodiment 1, the only difference is that the cover clamp is divided into two parts that are symmetrical up and down, and is arranged on the core changing sleeve 304 The sleeve connecting piece 305 is connected into one; the core changing sleeve 304 covers the end of the fuse sleeve, so that the fuse sleeve is fixedly connected with the cover clamp; the sleeve connecting piece can be adjusted by bolts. The gap distance between the upper and lower parts of the board clamp.

[0040] The sleeve connector 305 includes connecting pieces and bolts; the connecting pieces are symmetrically arranged on the edges of the upper and lower core changing sleeves, and the connecting pieces are provided with threaded holes, and the bolts are vertically screwed into the upper and lower threaded holes, so that the upper and lower , The lower connecting piece is...

Embodiment 3

[0041] Embodiment 3: see Figures 1 to 5 , the portable 35KV fuse core replacement device of this embodiment is basically the same as that of Embodiment 2, the only difference is that the size and shape of the terminal cover 4 matches the fuse sleeve 1, and the terminal cover is outward Extend the cover plate protrusion 401 corresponding to the track slot 303; the cover plate protrusion 401 is provided with a cover plate screw hole 402, and the cover plate fixing bolt 301 as the engaging part is screwed into the cover plate screw hole 402 Inside.

[0042] The terminal cover plate 4 is made of aluminum material, the core changing end plate 302, the core changing sleeve 304, the sleeve connector 305 and its bolts are made of stainless steel; the core changing end plate 302 and the core changing sleeve 304 are integrated Formed, the cover raised portion 401 is welded around the terminal cover 4 .

[0043] The specifications of the following parts are: terminal cover plate 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com