Method and apparatus for separating adhesive tapes

A technology of peeling device and adhesive tape, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problems of inability to perform the peeling function and reduced adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

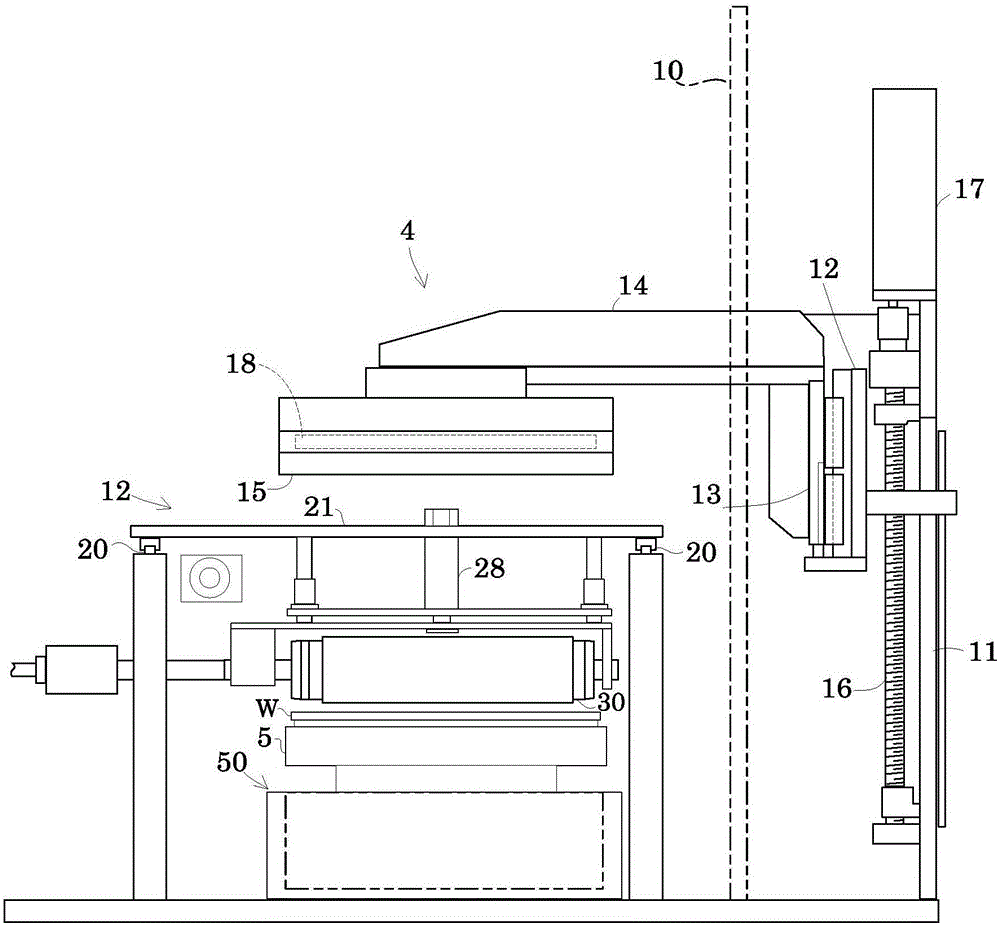

[0046] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

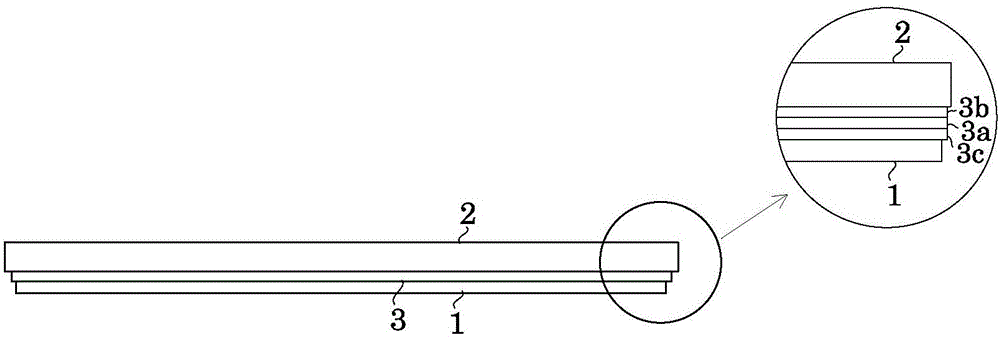

[0047] The adhesive tape peeling apparatus of this invention is provided in a support plate separation apparatus. That is, if figure 1 As shown, the adhesive tape peeling device is used to attach the support plate 2 made of stainless steel, glass substrate or silicon substrate concentrically to the support plate 2 via the double-sided adhesive tape 3 before back grinding. A device for separating a wafer 1 (hereinafter, appropriately referred to as “wafer 1 ”) from the support plate 2 . In addition, the support plate 2 has substantially the same shape as the wafer 1 , and its diameter is equal to or larger than the diameter of the wafer 1 .

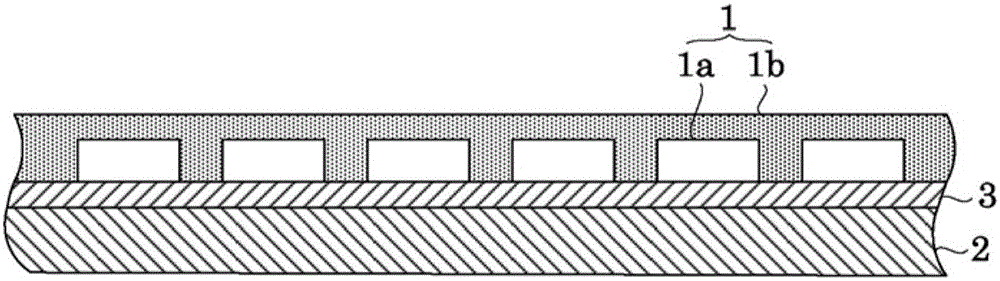

[0048] Here, wafer 1 is formed as follows. Bare chips 1 a obtained by performing a dicing process after forming circuits on the wafer surface are inspected, and only qualified bare chips 1 a are screened out. In such a manner t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com