Flexible display apparatus and preparation method therefor

A flexible display device and display film technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reducing the accessibility of packaging, easy cracks at the edge film interface, water and oxygen intrusion, etc., to achieve Improve edge reliability, improve water and oxygen barrier ability, and ensure the effect of display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

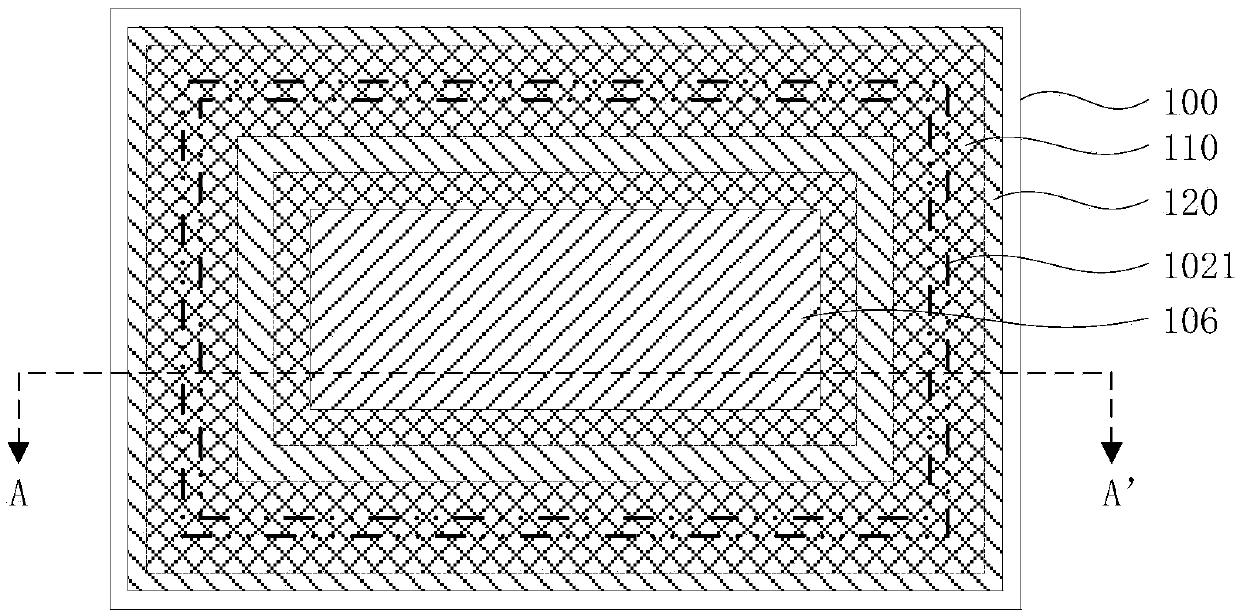

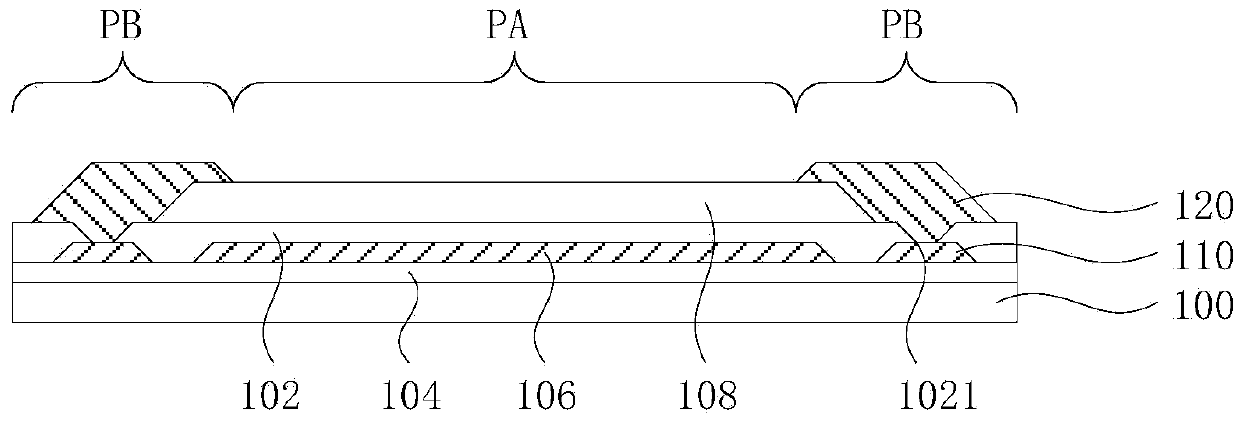

[0029] Please refer to figure 1 with figure 2 , figure 1 It is a schematic top view structure diagram of a flexible display device provided in Embodiment 1 of the present invention, figure 2 yes figure 1 Schematic diagram of the cross-sectional structure along the AA' section in the middle. A flexible display device provided in this embodiment includes: a flexible substrate 100 including a display area PA and a packaging area PB; a packaging substrate 110 located in the packaging area PB of the flexible substrate 100; a display film layer comprising at least one The first display film layer 102 on the packaging substrate 110, the first display film layer 102 has a first via hole 1021 on the packaging substrate 110 to expose at least part of the packaging substrate 110; the thin film packaging layer 108 covers the display The film layer extends from the display area PA to the packaging area PB, and the edge of the thin film packaging layer 108 is closer to the display are...

Embodiment 2

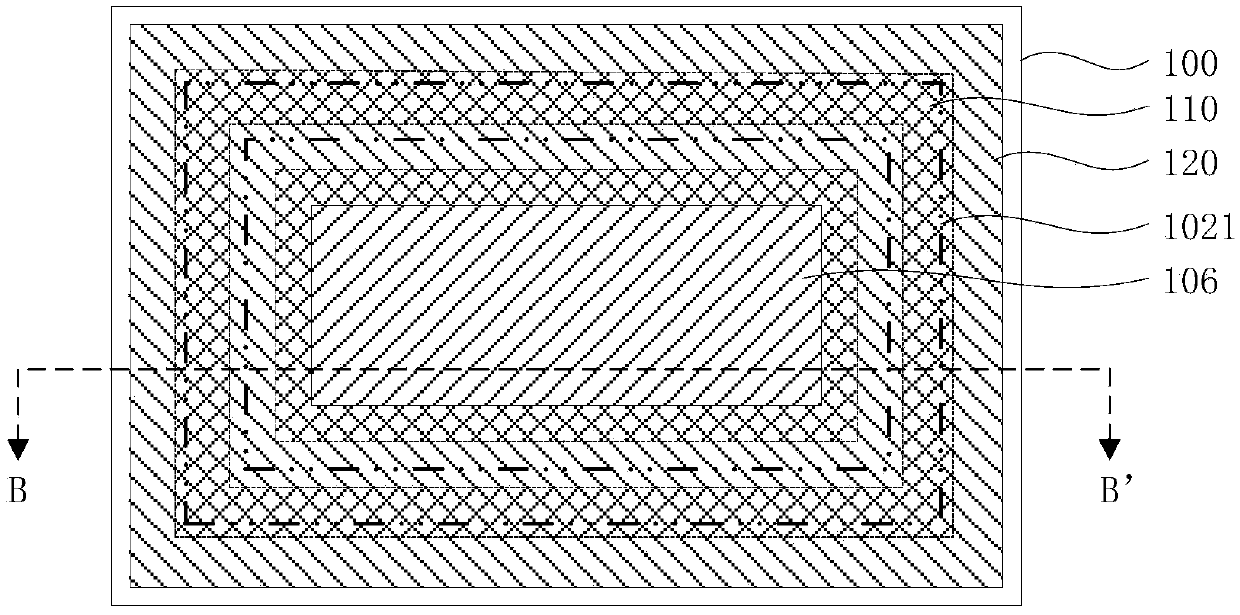

[0041] Please refer to image 3 with Figure 4 , image 3 It is a schematic top view structural diagram of a flexible display device provided in Embodiment 2 of the present invention, Figure 4 yes image 3 Schematic diagram of the cross-sectional structure along the BB' section in the middle. A flexible display device provided in this embodiment includes: a flexible substrate 100 including a display area PA and a packaging area PB; a packaging substrate 110 located in the packaging area PB of the flexible substrate 100; a display film layer comprising at least one The first display film layer 102 on the packaging substrate 110, the first display film layer 102 has a first via hole 1021 on the packaging substrate 110 to expose at least part of the packaging substrate 110; the thin film packaging layer 108 covers the display The film layer extends from the display area PA to the packaging area PB, and the edge of the thin film packaging layer 108 is closer to the display ar...

Embodiment 3

[0047] Please refer to Figure 5 as well as Figures 6A-6G , Figure 5 is a schematic flow chart of a method for preparing a flexible display device provided in Embodiment 3 of the present invention, Figures 6A-6G It is a schematic cross-sectional structure diagram of a method for manufacturing a flexible display device provided in Embodiment 3 of the present invention. In this embodiment, with figure 2 The flexible display device shown in is taken as an example to illustrate the preparation method of the flexible display device. A method for manufacturing a flexible display device provided in this embodiment includes: preparing a flexible substrate 100, the flexible substrate 100 including a display area PA and a packaging area PB; forming a packaging substrate 110 in the packaging area PB of the flexible substrate 100; A first display film layer 102 is formed on the package substrate 110, and the first display film layer 102 covers the package substrate 110; a first vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com