Stack-folding type electrode assembly and manufacturing method therefor

An electrode assembly and folding technology, which is applied in secondary battery manufacturing, secondary batteries, small flat batteries/batteries, etc., can solve the problems of electrode active material detachment, low design freedom, low space utilization, etc., and achieve folding Effects of reduced size tolerance and defect ratio, increased degrees of freedom, and freedom in cell design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

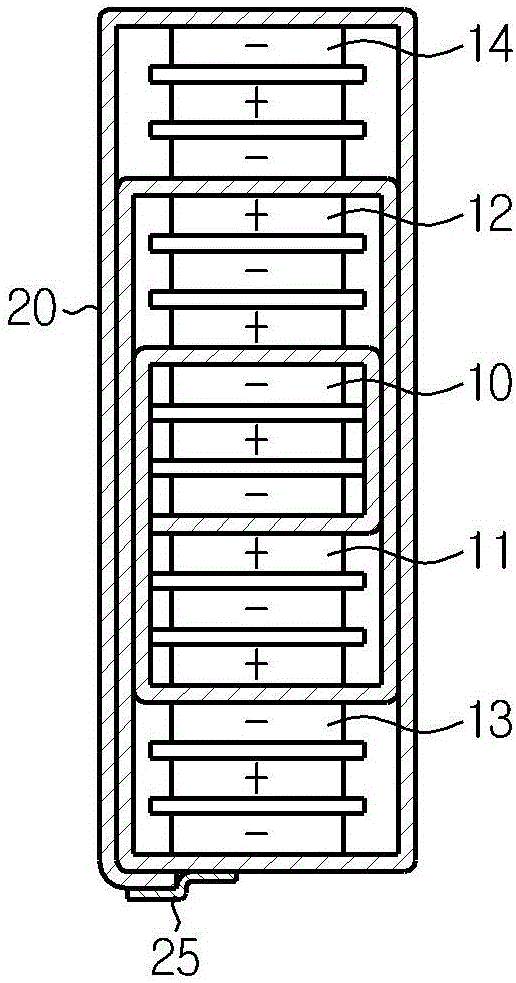

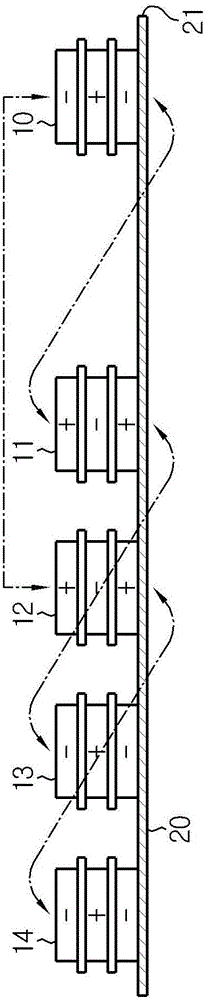

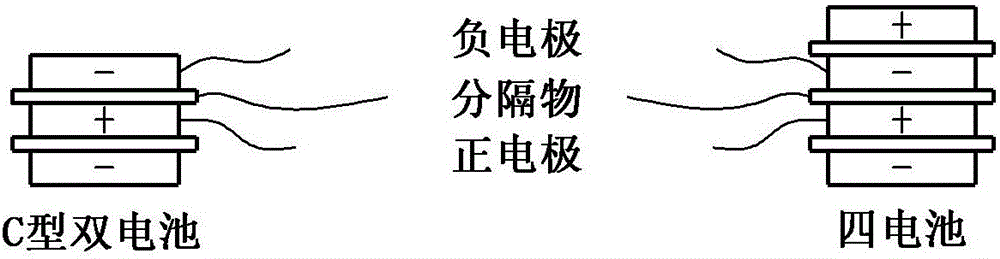

[0052] Hereinafter, preferred embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. Before the description, it should be understood that the terms used in this specification and the appended claims should not be interpreted as limited to the general dictionary meaning, but should be interpreted based on the meaning and concept corresponding to the technical aspect of the present disclosure, which is Based on the principle that the inventors are allowed to properly define terms for best interpretation.

[0053] It should also be understood that battery packs or electrode assemblies encompassed by the present disclosure include all types without being limited to specific types, for example, those having a plurality of stacked unit cells wound with folded separator sheets cut into an elongated shape A stacked-folded electrode assembly and a Z-shaped stacked electrode assembly having stacked single cells wound by folding in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com