Cable paying-off machine

A pay-off and axis technology, which is applied in the direction of cable laying equipment, etc., can solve the problems of heavy workload, small space, damage to the outer skin, etc., and achieve the effects of improving speed and quality, saving labor costs, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

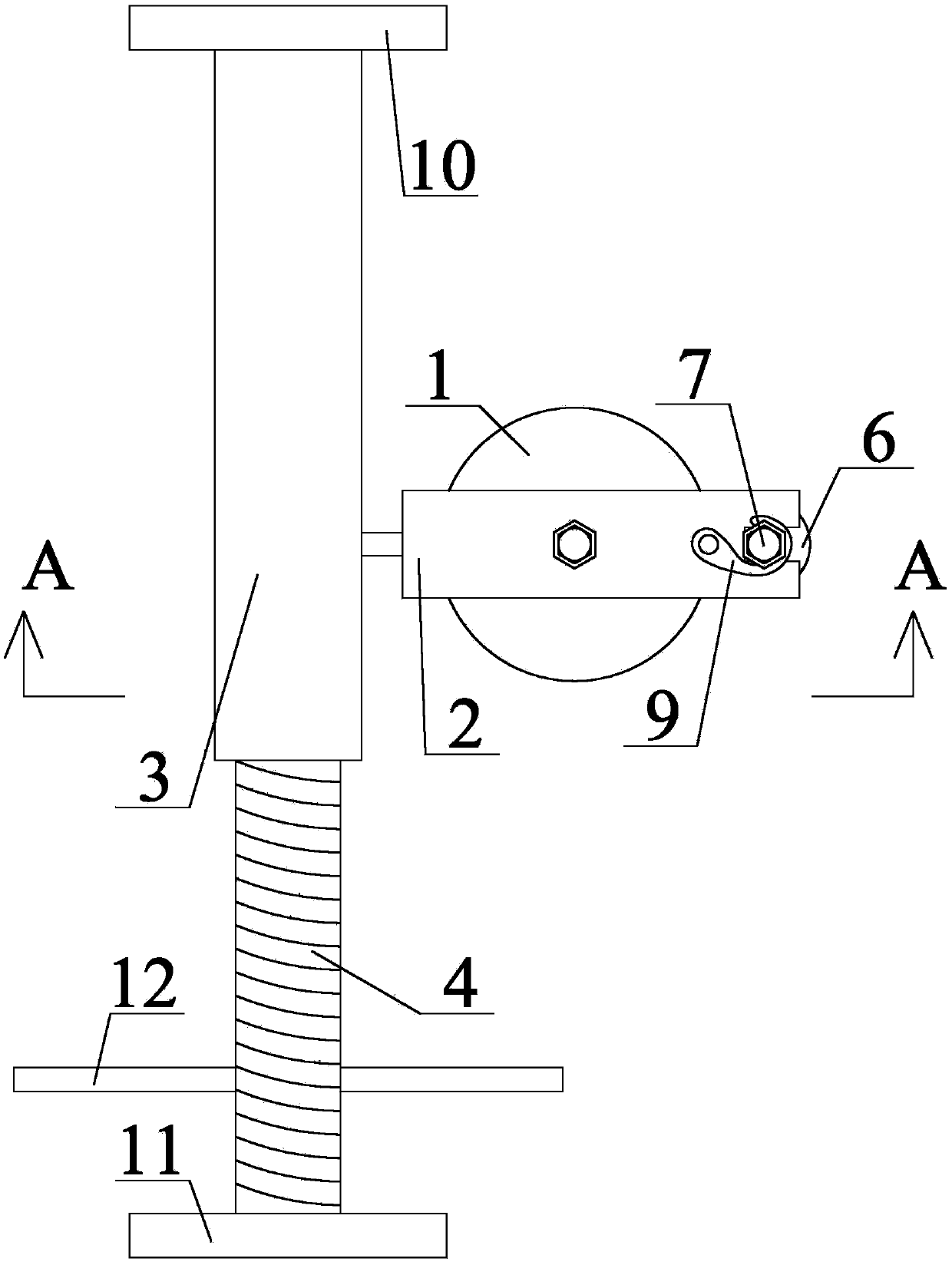

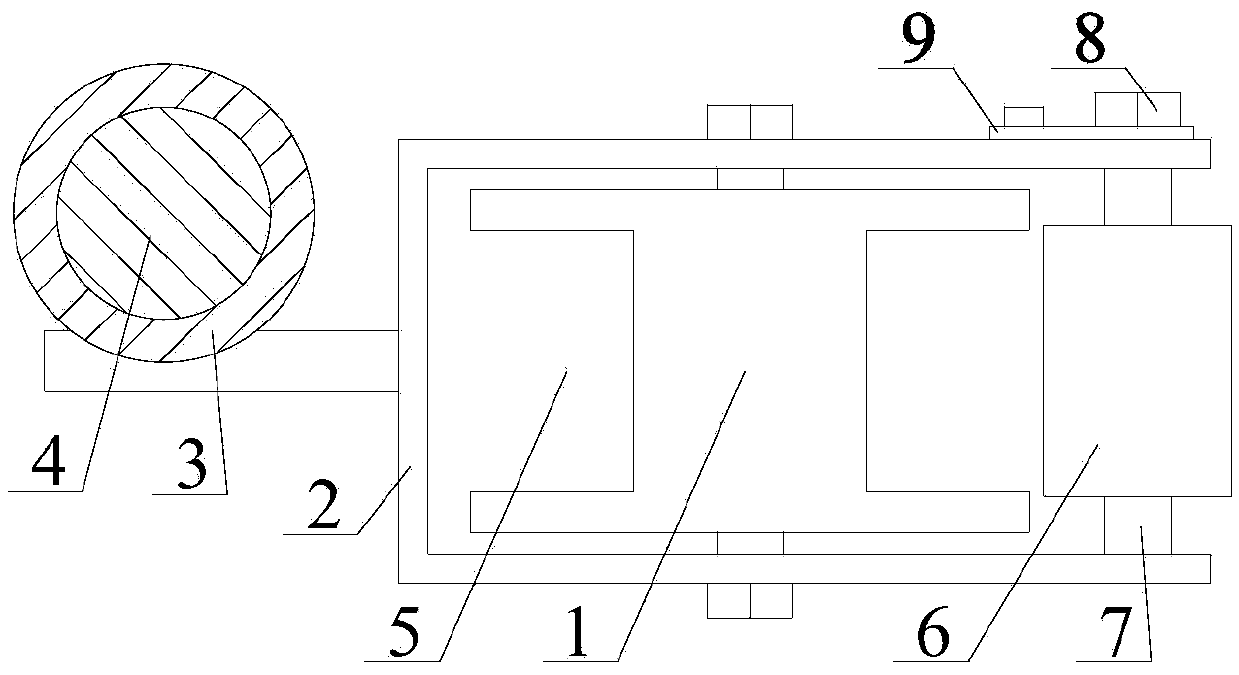

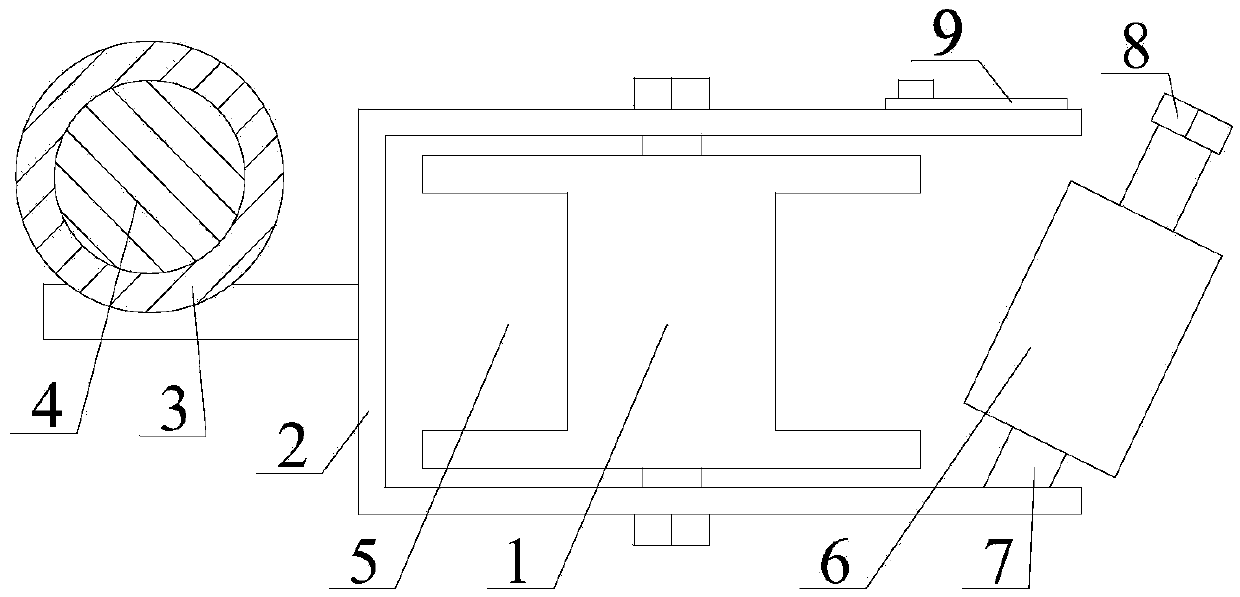

[0020] Specific examples, such as figure 1 , figure 2 and image 3 As shown, a pay-off device includes a length adjustment rod, a thread wheel 1 and a clip 2, the length adjustment rod is arranged horizontally, the length adjustment rod includes a fixed rod 3 and a telescopic rod 4, and the fixed rod 3 is set on the outside of the telescopic rod 4, The telescopic rod 4 is elongated or shortened in the fixed rod 3 and forms a locking fit with the fixed rod 3. The wire passing wheel 1 is arranged on one side of the fixed rod 3 and the axis of the wire passing wheel 1 is vertically arranged. The clip 2 is formed by the upper The clamping structure composed of the splint and the lower splint, one end of the clip 2 is an open end, the other end of the clip 2 is a closed end, the open end of the clip 2 is facing the side away from the fixed rod 3, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap