Phase commutation process control apparatus and method for marine high-power brushless direct current motor apparatus

A brushed DC motor and process control technology, which is applied in the fields of excitation or armature current control, etc., can solve the problems of little research on the commutation process control technology of marine high-power brushless DC motor devices, and the application technology has not yet been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

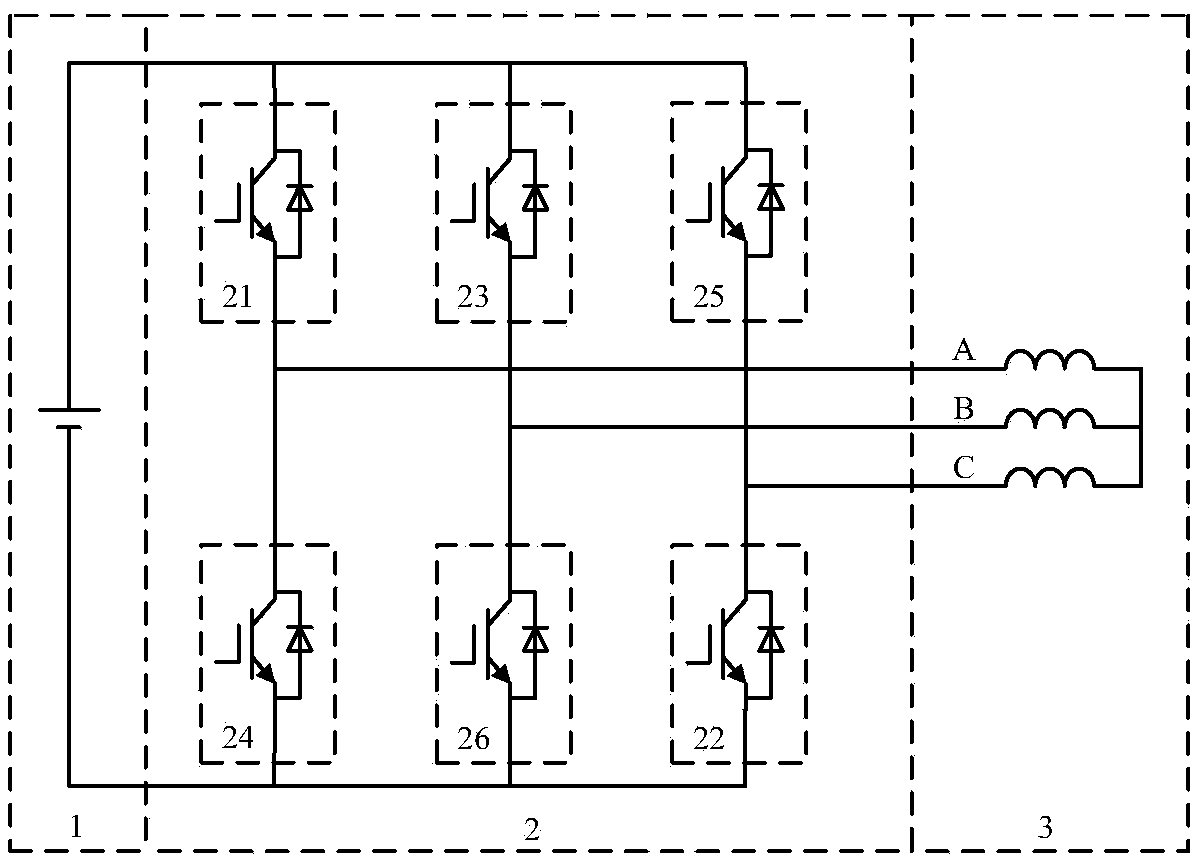

[0018] Such as figure 1 As shown, the present invention provides a commutation process control device for a marine high-power brushless DC motor device, which is used to control the commutation process of the brushless DC motor 3. The control device includes a DC voltage source 1 and a three-phase A full-bridge inverter 2, wherein the three-phase full-bridge inverter 2 is composed of six power tubes 21-26 connected in series to form three bridge arms and then connected in parallel. Specifically, the source of the power tube 21 is connected to the power tube 24, the source of power tube 23 is connected to the drain of power tube 26, the source of power tube 25 is connected to the drain of power tube 22, and the drains of power tubes 21, 23, 25 are connected together and commonly connected The positive pole of the DC voltage source 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com