Adsorption type polyester bottle label removing machine

An adsorption type polyester bottle technology, applied in cleaning hollow objects, recycling technology, plastic recycling, etc., can solve the problems of unstable cleaning rate of polyester bottles, label paper cannot be completely sucked out by the suction fan, etc., to maintain The effect of cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

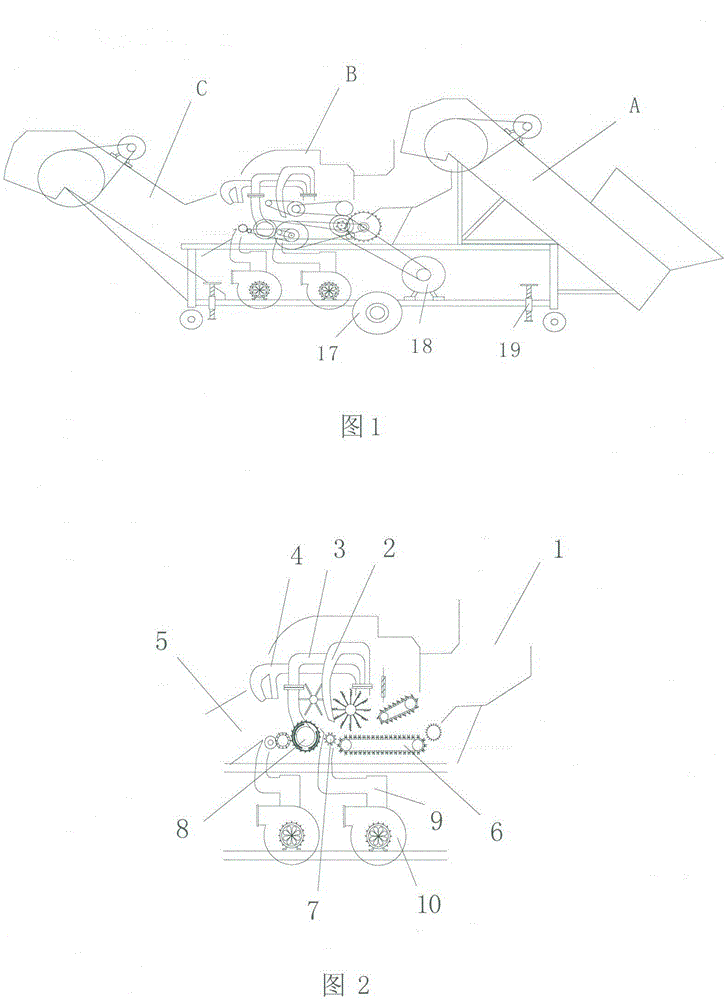

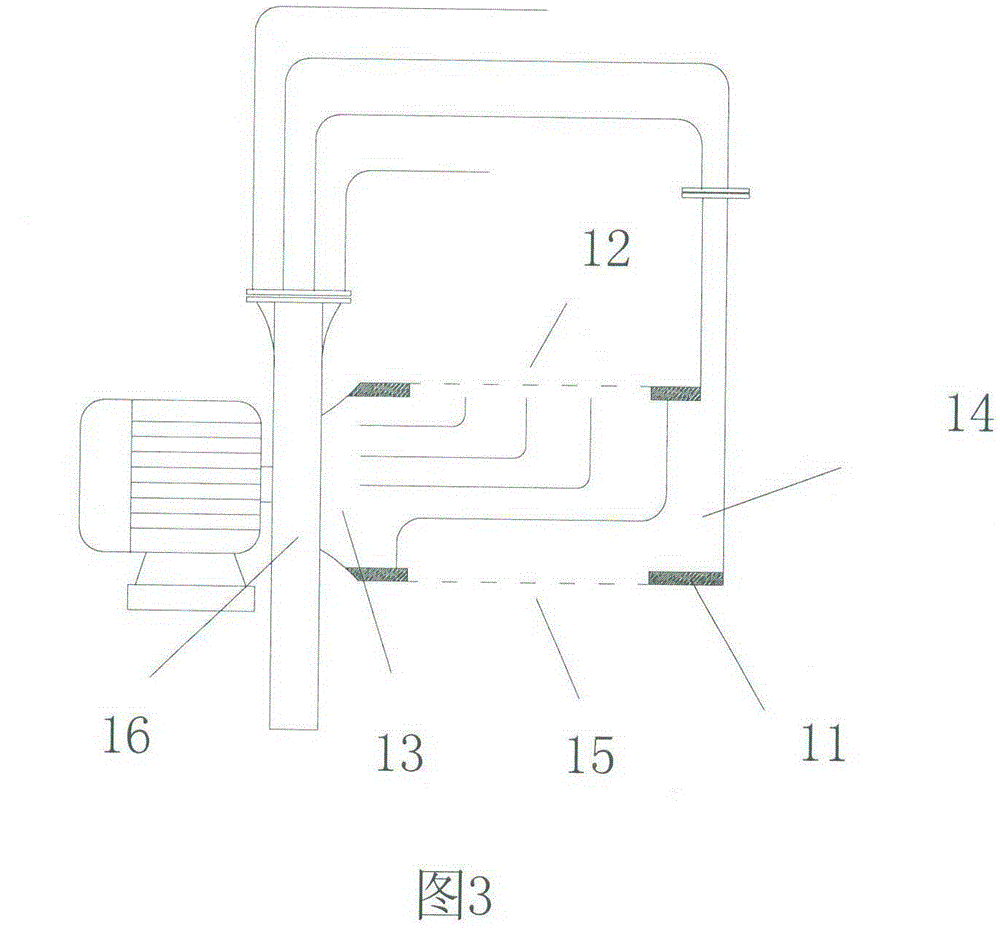

[0019] The structure schematic diagram of a kind of adsorption type polyester bottle delabeling machine of the present embodiment is as follows figure 1 As shown, this kind of adsorption type polyester bottle delabeling machine includes a feeding part A, a fuselage part B and a discharging part C; Blowing channel 3, lower layer blowing channel 4, transmission chain group 6, zigzag transmission roller 7, adsorption roller 8, suction channel 9, low-pressure suction fan 10, discharge port 5, high-pressure fan 16, rubber tire 17, main Transmission motor 18, stabilizing bolt 19; said zigzag conveying roller 7 is arranged horizontally between the conveying chain group 6 and the adsorption roller 8, and the surface of the zigzag conveying roller 7 is parallel and equally spaced to be provided with ring-shaped steel The steel sheet is per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com