Electric full-suspension wheel set force-transfer pin disassembling device

A disassembly device and power transmission pin technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, inability to reuse, and long disassembly time, so as to reduce labor intensity, improve work efficiency, The effect of improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

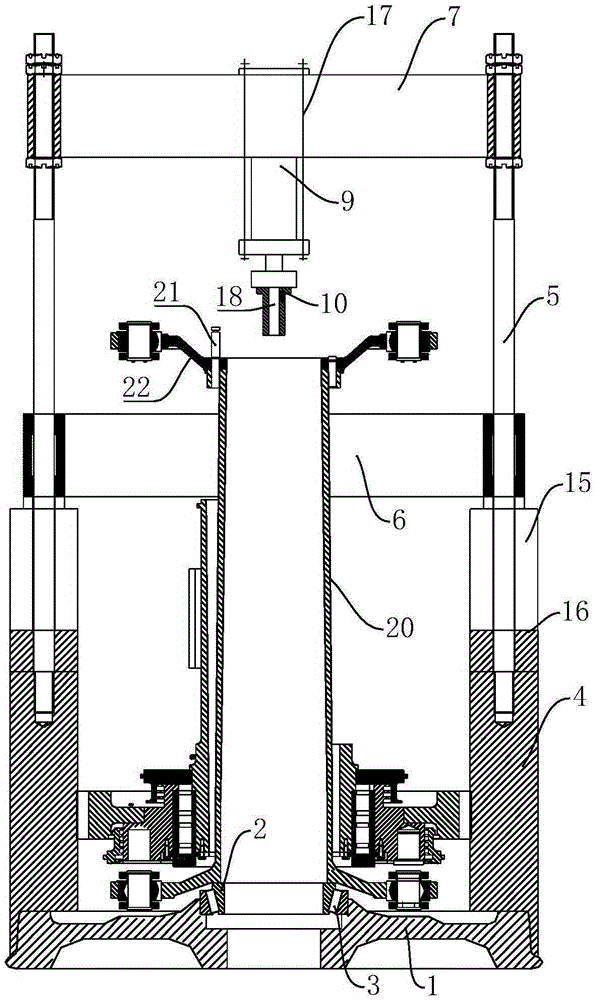

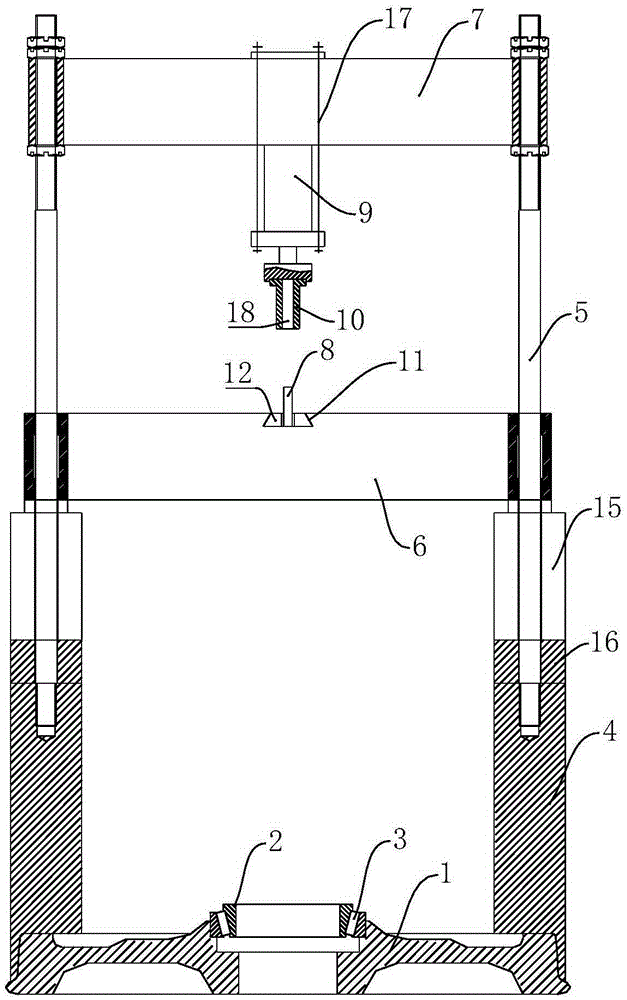

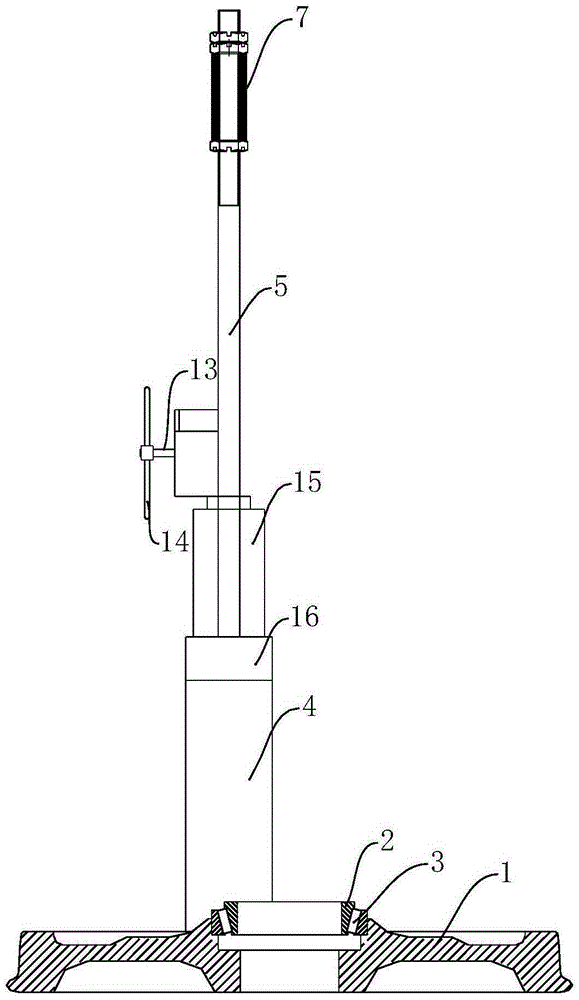

[0026] Such as figure 2 and 3 , which is a dismounting device for power transmission pins of electric fully suspended wheel sets, including a base 1, a support seat 2 is arranged in the center of the base 1, and the support seat 2 and the base 1 are connected by bearings 3; two sides of the base 1 are provided Column 4, guide column 5 is fixedly installed on column 4 respectively; Hollow oil cylinder 15 is respectively installed on column 4 on both sides, and guide column 5 passes through hollow oil cylinder 15, and hollow oil cylinder 15 is set on guide column 5; 6 two ends are provided with connecting holes 23, and the guide pillars 5 pass through the connecting holes 23 at the two ends of the movable beam 6 respectively, so that the movable beam 6 is movably connected on the guide pillars 5, and the movable beam 6 moves up and down along the guide pillars 5; They...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com