Automated control system for the production of caramel coloring

An automatic control and caramel pigment technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of long holding time, long heating time, and immature operation, so as to reduce the heating time and reduce the Operational accidents, the effect of avoiding personnel operating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

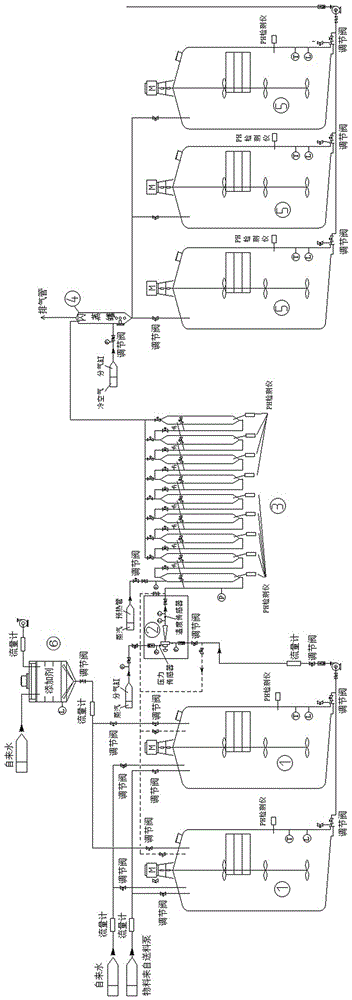

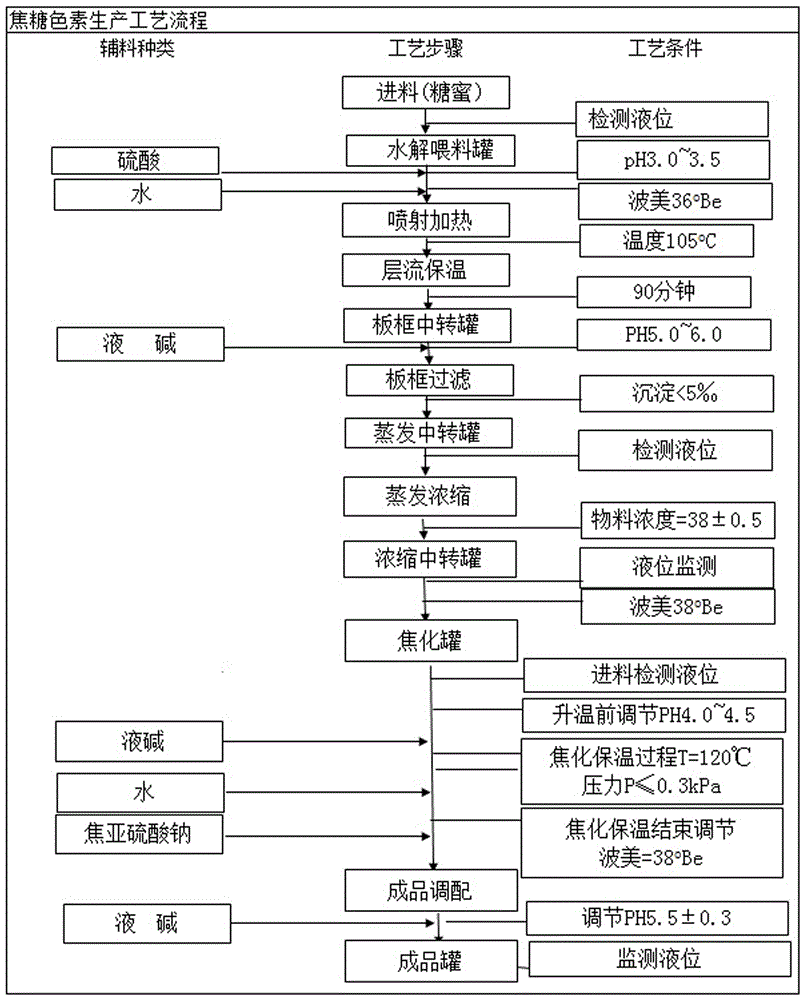

[0031]An automatic control system for the process of producing caramel pigment, which is to automatically control the equipment for producing caramel pigment according to the process conditions during the production process. The equipment for producing caramel pigment includes auxiliary material tanks, material pre-melting tanks, spray heating device, laminar flow reaction tank, flash tank, coking batching tank and finished product tank, which are connected with pipelines in turn, where the flash tank includes a plate and frame transfer tank, evaporation transfer tank and concentration transfer tank, and a central control system is set in the central control room , a flow meter and a regulating valve are installed on the inlet and outlet pipes of the material pre-melting tank, and the flow meter and the regulating valve are connected to the central control system; a temperature sensor, a pressure sensor and a steam regulating valve are installed on the heating pipe of the inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com