Low-fuel-air-ratio combustor

A burner, air ratio technology, applied in burners, combustion methods, combustion types, etc., can solve the problems of fuel utilization and combustion efficiency affecting production costs, low fuel utilization, combustion rate, and low combustion rate, etc. The mixing speed is fast and uniform, the combustion efficiency is improved, and the particles are small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

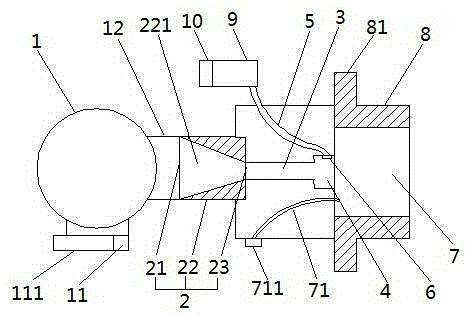

[0020] combine Figure 1 to Figure 2 An embodiment of a low air ratio burner of the present invention will be further described.

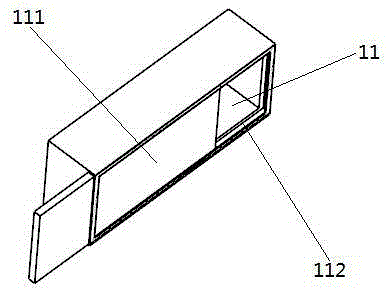

[0021] A low air ratio burner, comprising a fan 1, an air inlet 11 is arranged below the fan 1, and the air inlet 11 has a baffle 111, and the air outlet 12 of the fan 1 is connected to the induced air box 2, and the induced air box 2 includes an air inlet 21, a box body 22, and an air outlet 23, the air inlet 21 is connected to the air outlet 12, the inside 22 of the box is an air induction chamber 221, and the air induction chamber 221 is in the shape of a truncated cone. The air outlet 23 is connected to the air passage 3, the air passage 3 is connected to the mixing chamber 4, the mixing chamber 4 is connected to the fuel passage 5, and a fuel atomizer 6 is arranged at the connection between the fuel passage 5 and the mixing chamber 4, and the The mixing chamber 4 is connected to the combustion head 7, the ignition electrode 71 is arranged ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com